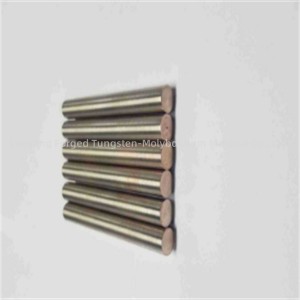

Izinga lokushisa eliphezulu kanye ne-high melting point wire tungsten

Ukukhiqizwa kwentambo ye-tungsten kuhilela izinyathelo ezimbalwa ezibalulekile, ngokuvamile eziqala ngokukhipha insimbi ye-tungsten bese icutshungulwa ibe ifomu locingo. Okulandelayo isingeniso esifushane sendlela yokukhiqiza yocingo lwe-tungsten:

1. Imayini ye-Tungsten ore: I-Tungsten ivamise ukukhishwa ku-ore, ngokuvamile ngendlela yamaminerali e-tungsten oxide, njenge-scheelite noma i-wolframite. I-ore iyambiwa futhi icutshungulwe ukuze kukhishwe i-tungsten concentrate.

2. Ukuguqulwa ku-tungsten powder: I-concentrate ye-tungsten ibe isiguqulwa ngamakhemikhali ibe yi-tungsten oxide, ephinde yehliswe ngenqubo ebizwa ngokuthi i-tungsten oxide ukunciphisa ukuze kukhiqizwe i-tungsten powder. Le powder ye-tungsten iyinhloko yokusetshenziswa kocingo lwe-tungsten.

3. Ukuhlanganiswa kwe-Powder: I-tungsten powder ihlanganiswe ngaphansi kwengcindezi ephezulu ukuze yakhe ibhulokhi eqinile, bese i-sintered ekushiseni okuphezulu ukuze yakhe i-tungsten billet eqinile. Le billet isetshenziswa njengempahla eluhlaza yokukhiqiza induku yocingo.

4. Umdwebo: I-tungsten billet ibe isicutshungulwa ngochungechunge lwemisebenzi yokudweba, idonswe ngochungechunge lwama-dies ukuze kuncishiswe ububanzi bayo obuyisayizi oyifunayo. Inqubo ingase ihlanganise izinyathelo eziningi zokudweba ukuze kuzuzwe ububanzi bocingo lokugcina.

5. Ukufakwa kwe-Annealing: Intambo ye-tungsten edonsayo kufanele idlule enqubweni yokudonsa, lapho ucingo lushiselwa ezingeni lokushisa elithile bese lupholiswa kancane ukuze kuqedwe ukucindezelwa kwangaphakathi futhi kuthuthukiswe ukuduka kwayo nokuguquguquka.

6. Ukwelashwa okungaphezulu: Intambo ye-Tungsten ingaphathwa ngaphezulu, njengokuhlanza, ukumbozwa noma okunye ukuguqulwa kwendawo, ukuze kuthuthukiswe ukusebenza kwayo kwezinhlelo ezithile zokusebenza.

7. Ukulawulwa kwekhwalithi: Kuyo yonke inqubo yokukhiqiza, izinyathelo zokulawula ikhwalithi ziyasetshenziswa ukuze kuqinisekiswe ukuthi intambo ye-tungsten ihlangabezana nezidingo ezicacisiwe zobukhulu, zemishini namakhemikhali.

Sekukonke, ukukhiqizwa kocingo lwe-tungsten kuhilela uchungechunge lwezinyathelo ezilawulwa ngokucophelela, kusukela ekukhishweni kwensimbi ye-tungsten kuya ekudwebeni kokugcina nokucutshungulwa. Inqubo idinga ukunemba nobungcweti ukuze kukhiqizwe ucingo lwe-tungsten olusezingeni eliphezulu olufanele izinhlelo zokusebenza ezihlukene zezimboni.

I-Tungsten wire isetshenziswa kabanzi ezimbonini ezahlukahlukene ngenxa yezakhiwo zayo ezihlukile. Ezinye izinto ezisetshenziswayo ze-tungsten wire zihlanganisa:

1. Ukukhanyisa: I-Tungsten filament isetshenziswa kakhulu ekukhiqizeni ama-incandescent amalambu namalambu e-halogen. Ngenxa yezinga eliphezulu lokuncibilika kanye nokuhamba kahle kukagesi, isetshenziswa njengefilament kulezi zicelo zokukhanyisa.

2. Izinto zikagesi nezikagesi: Intambo ye-Tungsten isetshenziswa ezintweni ezihlukahlukene zikagesi nezikagesi, okuhlanganisa amashubhu evacuum, amashubhu e-cathode ray (CRT), kanye nemishini yokushisela i-electron beam. Iphuzu layo eliphezulu lokuncibilika kanye nokumelana nokwanda kokushisa kuyenza ifanele lezi zicelo zokushisa okuphezulu.

3. Izakhi zokushisa: Intambo ye-Tungsten isetshenziselwa ukukhiqiza izinto zokushisisa zezithando zokushisa eziphezulu, imishini yokukhiqiza i-semiconductor, nezinye izinhlelo zokusebenza zokushisa ezimbonini. Ikhono layo lokumelana namazinga okushisa aphakeme kakhulu ngaphandle kokuguqulwa noma i-oxidation iyenza ibe yigugu kulokhu kusetshenziswa.

4. I-Aerospace kanye Nokuvikela: I-Tungsten filament isetshenziswa kwi-aerospace nezinhlelo zokuvikela, njengezintambo ezisetshenziswa ekukhiqizeni amasistimu okuqondisa imicibisholo, izinyathelo zokuphikisa zika-elekthronikhi, nezinye izisetshenziswa zezempi ze-elekthronikhi.

5. Imishini yezokwelapha: Intambo ye-Tungsten isetshenziswa emishinini yezokwelapha, okuhlanganisa amashubhu e-X-ray, imishini yokwelapha nge-radiotherapy nezinsimbi ezihlukahlukene zokuhlinza. Ukuminyana kwayo okuphezulu namandla kuyenza ifanele lezi zicelo zezokwelapha ezibucayi.

6. Ukuhlunga nokuhlola: I-Tungsten wire mesh isetshenziswa ekuhlungeni nasekuhloleni izinhlelo zokusebenza ezimbonini ezinjengokucubungula amakhemikhali, i-aerospace, nezimoto. Amandla aphezulu entambo yocingo kanye nokumelana nokugqwala kuyenza ifanelekele lezi zindawo ezinokhahlo.

7. Izinzwa Zokushisa Eziphakeme: Intambo ye-Tungsten isetshenziselwa ukwakha izinzwa zokushisa eziphezulu zezinhlelo zokusebenza zezimboni, ezifana nokuqapha nokulawula izinqubo zokushisa okuphezulu ezindaweni zokukhiqiza nezokucwaninga.

Sekukonke, inhlanganisela eyingqayizivele yendawo yokuncibilika okuphezulu, ukuqhutshwa kukagesi, namandla kwenza intambo ye-tungsten ibe yinto ebalulekile enezinhlobonhlobo zezinhlelo zokusebenza ezimbonini ezifana nezibani, izinto zikagesi, i-aerospace, ezokwelashwa, nezimboni zokukhiqiza.

| Igama Lomkhiqizo | Izinga lokushisa eliphezulu kanye ne-high melting point wire tungsten |

| Okubalulekile | W |

| Ukucaciswa | Kwenziwe ngokwezifiso |

| Ubuso | Isikhumba esimnyama, i-alkali egeziwe, epholishiwe. |

| Icebo | Sintering inqubo, machining |

| Iphuzu elincibilikayo | 3400 ℃ |

| Ukuminyana | 19.3g/cm3 |

Ingxoxo: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com