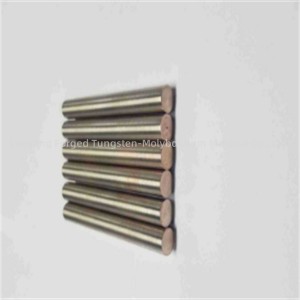

High Hardness Tungsten yethusi Ingxubevange Round Rod

Ukukhiqizwa kwe-tungsten copper alloy round rods ngokuvamile kudinga inqubo ecophelelayo ukuze kuqinisekiswe ukuthi izinto ezibonakalayo ezidingekayo ziyafinyelelwa. Okulandelayo yizinyathelo ezijwayelekile zokukhiqizwa kwezinduku eziyindilinga ze-tungsten copper alloy:

Ukukhethwa kwempahla eluhlaza: Impushana ye-tungsten ene-high-purity ne-copper powder ikhethwa njengezinto zokusetshenziswa eziyinhloko ze-alloy. Ukukhethwa kwalezi zinto zokusetshenziswa kubalulekile ukuze kuzuzwe izakhiwo ezidingekayo zemishini, ezishisayo nezikagesi zomkhiqizo wokugcina. Ukuxuba I-Powder: I-Tungsten powder ne-powder yethusi kuxutshwe kahle ngezilinganiso ezilawulwayo ukuze kutholwe ukwakheka kwe-alloy oyifunayo. Lesi sinyathelo sokuxuba sibalulekile ukuze kuqinisekiswe ukusatshalaliswa okulinganayo kwezithako ngaphakathi kwe-alloy. I-Compaction: I-powder ehlanganisiwe ihlanganiswe ngaphansi kwengcindezi ephezulu ukuze yakhe umzimba oluhlaza onomumo oyifunayo. Le briquetting isinyathelo sokuqala ekubumbeni impahla eluhlaza ibe yisimo senduku oyifunayo. I-Sintering: Umzimba oluhlaza ube usushiswa ngezinga lokushisa eliphezulu endaweni elawulwayo ukuze ubophe izinhlayiya ze-tungsten nezethusi futhi uzuze ukuminyana okudingekayo namandla okusebenza. Ukucutshungulwa kwe-thermal: I-sintered material ingaphansi kwezinqubo zokucubungula ezishisayo ezifana ne-extrusion noma i-forging ukuze kuthuthukiswe ukubunjwa nokucwenga okokusebenza kube yisimo senduku eyindilinga. Ukwelashwa Kokushisa: Isitokwe senduku singangena inqubo yokwelashwa kokushisa ukuze sithuthukise izakhiwo zaso zomshini njengamandla nokuqina. Ukulawulwa kwekhwalithi: Phakathi nayo yonke inqubo yokukhiqiza, izinyathelo zokulawula ikhwalithi ziyamukelwa ukuze kuqinisekiswe ukuthi ukwakheka, usayizi kanye nezakhiwo zemishini yezinduku eziyindilinga ze-tungsten zethusi ezitholakalayo zihlangabezana nezidingo ezishiwo.

Ngokulandela lezi zinyathelo zokukhiqiza, abakhiqizi bangakhiqiza ama-tungsten copper alloy round rods anezakhiwo ezifunwayo, abenze bafanelekele uhla olubanzi lwezicelo zezimboni.

I-tungsten copper alloy round rods isetshenziswa kabanzi emikhakheni ehlukahlukene ngenxa yezakhiwo zayo ezihlukile. Nazi ezinye izinto ezisetshenziswayo ezijwayelekile zama-tungsten copper alloy round rods:

I-Electrical and Thermal Conductivity: Ama-tungsten copper alloy round rods asetshenziswa ezinhlelweni ezidinga ukuguquguquka okuphezulu kwe-thermal kanye nogesi, njengokuthintana kukagesi, osinki okushisa, nama-electrodes e-electrical discharge machining (EDM). Izinhlelo zokusebenza ezinokushisa okuphezulu: Indawo ephezulu yokuncibilika kanye ne-thermal conductivity enhle kakhulu ye-tungsten-copper alloy iyenza ifaneleke ukusetshenziswa ezindaweni ezishisa kakhulu, ezifana ne-aerospace nezinhlelo zokuvikela, ezingxenyeni ezinjengama-rocket nozzle kanye nezingxenye zesithando somlilo esishisa kakhulu. Ukumelana nokugqoka: Izinduku eziyindilinga ze-Tungsten zethusi ze-alloy zisetshenziswa ezinhlelweni ezidinga ukumelana nokugqokwa okuphezulu, njengokwakhiwa kwama-electrode wokushisela, othintana nabo kagesi kanye nezingxenye zesikhunta sepulasitiki. I-Radiation Shielding: Ukuminyana okuphezulu kwe-Tungsten-copper alloy kanye nezakhiwo ezinhle kakhulu zokuvikela imisebe kuyenza ifanelekele ukusetshenziswa kwezokwelapha nezenuzi, njengemishini yokwelapha ngemisebe kanye nezingxenye zokuvikela imisebe. I-Aerospace kanye Nezokuvikela: Izinti eziyindilinga ze-Tungsten zethusi ze-alloy zisetshenziswa ku-aerospace kanye nezicelo zokuzivikela ngenxa yamandla azo aphezulu, ukuzinza kwe-thermal kanye nekhono lokumelana nezimo ezimbi kakhulu, okuzenza zifaneleke izingxenye ezifana nama-propellant chambers, ama-rotor blades nama-projectiles abhoboza izikhali.

Sekukonke, inhlanganisela eyingqayizivele yezakhiwo ezivezwa yi-tungsten-copper alloy round rods izenza zibe wusizo ezinhlobonhlobo zezinhlelo zokusebenza ze-aerospace, ezokuvikela, zikagesi, nezimboni zokukhiqiza.

| Igama Lomkhiqizo | I-Tungsten Copper Alloy Round Rod |

| Okubalulekile | W1 |

| Ukucaciswa | Ngokwezifiso |

| Ubuso | Isikhumba esimnyama, i-alkali egeziwe, epholishiwe. |

| Icebo | Sintering inqubo, machining |

| Iphuzu elincibilikayo | 3400 ℃ |

| Ukuminyana | 19.3g/cm3 |

Ingxoxo: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com