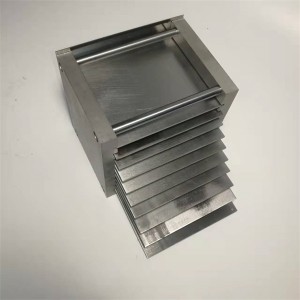

Imbiza enyibilikayo ye-tungsten crucible yeziko lobushushu obuphezulu

I-Tungsten crucible luhlobo lwemveliso ye-tungsten yensimbi, ngokukodwa eyahlulahlulwe yaba ziindidi ezimbini: i-sintering kunye ne-stamping. Inkqubo yokulungiselela i-tungsten crucible ibandakanya uhlobo lokujikeleza, uhlobo lwesitampu, njl.njl. Ezi nkqubo zenza i-tungsten crucible ibe noxinaniso oluphezulu, uburhabaxa obusezantsi, ukuqina okuhle kunye nobulukhuni, ngelixa ixabiso lemveliso liphantsi kakhulu, kwaye ixabiso lemveliso liphantsi kakhulu. .

Ukusetyenziswa okubanzi kwee-tungsten crucibles kuncedo kwiimpawu zabo ezibalaseleyo zomzimba kunye neekhemikhali, kubandakanywa indawo ephezulu yokunyibilika, amandla aphezulu, ukuxhathisa okulungileyo kokubola, kunye nokumelana nokunxiba. ...

| Imilinganiselo | Njengemfuno yakho |

| Indawo yeMvelaphi | Luoyang, Henan |

| Igama lebrand | FGD |

| Isicelo | Ishishini |

| Umphezulu | Ilungisiwe |

| Ubunyulu | 99.95% Min |

| Izinto eziphathekayo | I-tungsten ecocekileyo |

| Ukuxinana | 19.3g/cm3 |

| Indawo yokunyibilika | 3400℃ |

| Indawo yokusetyenziswa | Vacuum okusingqongileyo |

| Ubushushu bokusetyenziswa | 1600-2500℃ |

| Amacandelo aphambili | W-99.95% |

| Umxholo wokungcola≤ | |

| Pb | 0.0005 |

| Fe | 0.0020 |

| S | 0.0050 |

| P | 0.0005 |

| C | 0.01 |

| Cr | 0.0010 |

| Al | 0.0015 |

| Cu | 0.0015 |

| K | 0.0080 |

| N | 0.003 |

| Sn | 0.0015 |

| Si | 0.0020 |

| Ca | 0.0015 |

| Na | 0.0020 |

| O | 0.008 |

| Ti | 0.0010 |

| Mg | 0.0010 |

| Izinto eziphathekayo | 100% recrystallization ubushushu ℃ | (Ixesha lokumisa: 1 iyure)) |

|

| Deformation degree=90% | Deformation degree=99.99% |

| Ococekileyo W | 1350 | - |

| WVM | - | 2000 |

| WL10 | 1500 | 2500 |

| WL15 | 1550 | 2600 |

| WRe05 | 1700 | - |

| WRe26 | 1750 | - |

1. Umzi-mveliso wethu useLuoyang City, kwiPhondo laseHenan. I-Luoyang yindawo yemveliso yemigodi ye-tungsten kunye ne-molybdenum, ngoko ke sineenzuzo ezipheleleyo kumgangatho kunye nexabiso;

2. Inkampani yethu inabasebenzi bezobugcisa abaneminyaka engaphezu kwe-15 yamava, kwaye sibonelela ngezisombululo ezijoliswe kuzo kunye neengcebiso kwiimfuno zomthengi ngamnye.

3. Zonke iimveliso zethu zihlolwa ngokungqongqo umgangatho phambi kokuba zithunyelwe kumazwe angaphandle.

4. Ukuba ufumana iimpahla ezineziphene, unokuqhagamshelana nathi ukuze ubuyiselwe imali.

1. Lungisa i-tungsten powder

(Okokuqala, lungisa umgubo wetungsten kwaye uwukhuse ukwahlula umgubo orhabaxa kunye nocolekileyo wetungsten)

2. Ibhetshi edibeneyo

(Ukusetyenzwa kwebhetshi ye-tungsten powder enemichiza efanayo kodwa kwiinkqubo ezahlukeneyo zokuvelisa)

3. ukucinezela isostatic

(Faka i-tungsten powder edibeneyo kwisitya esitywiniweyo esizaliswe ngolwelo, kwaye ngokuthe ngcembe uyicinezele ngenkqubo yoxinzelelo ukuze unciphise umgama phakathi kweeathom, ukwandisa ingxinano, kunye nokuphucula iimpawu ezibonakalayo zempahla ngaphandle kokutshintsha ukubonakala kwayo)

4. Rugh billet machining

(Emva kokugqiba ucinezelo lwe-isostatic, ukusetyenzwa kwe-billet rough kuyenziwa)

5. Intermediate frequency sintering

(Beka i-billet erhabaxa esetyenzisiweyo kwisithando somlilo esiphakathi ukuze usebenze ngokuntywila)

6. Ukulungiswa kakuhle kwemoto

(Ukuguqula imveliso ene-sintered ukufumana imilinganiselo echanekileyo kunye neemilo)

7. Hlola ukupakishwa

(Hlola i-crucible tungsten esetyenzisiweyo kwaye uyipakishe emva kokuphumelela ukuhlolwa)

Ukunyibilika kweglasi yequartz: Izikhewu zeTungsten zikwasetyenziswa ngokubanzi kwiziko lokunyibilikisa iglasi yequartz. Njengenye yezixhobo ezibalulekileyo zokunyibilikisa iglasi yequartz, amandla abo obushushu obuphezulu kunye nokumelana nomhlwa kwenza ukuba iglasi yequartz inyibilike kwaye yenze ubume obunqwenelekayo kwindawo yobushushu obuphezulu.

I-deformation ye-crucible ibangelwa ukwandiswa okungalinganiyo kweendawo ezahlukeneyo ze-crucible ngenxa yokufudumala okugqithiseleyo kunye nokungalingani. Ukufudumeza okukhawulezayo kunye nokungalinganiyo kwe-crucible kufuneka kugwenywe.

Uluhlu lobushushu olucetyiswayo luyi-1600-2500 degrees Celsius.