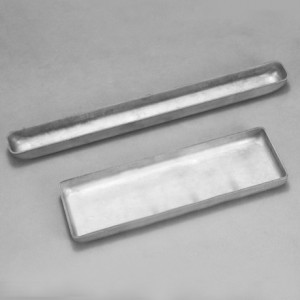

Izikrufu zeTantalum kunye neziqhoboshi ze nuts tantalum

Inkqubo yokuvelisa i-tantalum bolts kunye namantongomane ilandela ngokungqongqo imigangatho ephezulu yokuqinisekisa ukuqina kunye nokuthembeka kweemveliso. Bangakwazi ukumelana namaqondo obushushu aphezulu kakhulu kunye noxinzelelo, kwaye bagcine ukusebenza okuzinzileyo nakwimeko ezingqongileyo. Ke ngoko, iibholiti ze-tantalum kunye namantongomane ziqhele ukusetyenziswa kwimizi-mveliso kunye nezicelo zenzululwazi ezifunwa kakhulu, ezifana ne-aerospace, izibonelelo zenyukliya, kunye nokwenziwa kwezixhobo zonyango ezikumgangatho ophezulu. ...

| Imilinganiselo | Njengemfuno yakho |

| Indawo yeMvelaphi | Luoyang, Henan |

| Igama lebrand | FGD |

| Isicelo | Ishishini, isemiconductor |

| Ubunyulu | 99.95% |

| Indawo yokunyibilika | 2996℃ |

| Ukuxinana | 16.65g/cm3 |

| Ukuqina | HV250 |

| λ/nm | f | W | F | S* | CL | G |

| 271.5 | 0.055 | 0.2 | N / A | 30 | 1.0 | |

| 260.9(D) | 0.2 | N / A | 23 | 2.1 | ||

| 265.7 | 0.2 | N / A | 2.5 | |||

| 293.4 | 0.2 | N / A | 2.5 | |||

| 255.9 | 0.2 | N / A | 2.5 | |||

| 264.8 | 0.2 | N / A | x | |||

| 265.3 | 0.2 | N / A | 2.7 | |||

| 269.8 | 0.2 | N / A | 2.7 | |||

| 275.8 | 0.2 | N / A | 3.1 | |||

| 277.6 | 0.2 | N / A | 58 |

1. Umzi-mveliso wethu useLuoyang City, kwiPhondo laseHenan. I-Luoyang yindawo yemveliso yemigodi ye-tungsten kunye ne-molybdenum, ngoko ke sineenzuzo ezipheleleyo kumgangatho kunye nexabiso;

2. Inkampani yethu inabasebenzi bezobugcisa abaneminyaka engaphezu kwe-15 yamava, kwaye sibonelela ngezisombululo ezijoliswe kuzo kunye neengcebiso kwiimfuno zomthengi ngamnye.

3. Zonke iimveliso zethu zihlolwa ngokungqongqo umgangatho phambi kokuba zithunyelwe kumazwe angaphandle.

4. Ukuba ufumana iimpahla ezineziphene, unokuqhagamshelana nathi ukuze ubuyiselwe imali.

1. ukulungiswa kwezinto ekrwada

(Khetha imathiriyeli efanelekileyo yocingo okanye yebhodi ukuqinisekisa ukuba imathiriyeli iyahlangabezana neemfuno eziqhelekileyo.)

2. Ukucutshungulwa kocingo/ukunyathela

(Ucingo lusetyenzwa lube zizikrufu ezingenanto ngoomatshini bentloko ababandayo; Ishiti lentsimbi ligqojozwa kwizithuba zamandongomane kusetyenziswa ipunch press. Eli nyathelo lelokwenza ubume obusisiseko bebholithi kunye ne nut).

3. unyango lobushushu

(Ubushushu phatha indawo engenanto, njengokucinywa, ukucaphuka, njl. njl., ukuqinisa ubulukhuni kunye nokuqina, ukuqinisekisa iipropathi zomatshini zesibophelelo)

4. Ukuqengqeleka intambo / ukucofa amazinyo

(Iizithuba ezivaliweyo zithululwa kusetyenziswa umatshini wokuqengqeleka; Indongomane engenanto ilungiswa ngemisonto yangaphakathi kumatshini wokucofa)

5.Unyango lomphezulu

(Unyango oluphezulu olufana ne-electroplating, i-oxidation, i-phosphating, njl. njl. lwenziwa ngokweemfuno zokunyusa ukuxhathisa ukubola kunye nobuhle.

6. ukufumanisa

(Sebenzisa iigeyiji, izixhobo zamehlo, njl.njl. Ukuhlola ngokubanzi iimveliso ezigqityiweyo zobukhulu, ukuchaneka komsonto, iziphene zomhlaba, njl., Ukuqinisekisa umgangatho)

7. Ukuhlola kunye nokuPakisha

(Susa iimveliso ezingahambelaniyo ngomatshini wesikrini ongcangcazelayo, uzihlele ngokweenkcukacha, kwaye emva koko uzilungiselele okanye uzipakishe ngesandla)

8. ukulawula umgangatho

(Iisampulu zokuvavanya ukusebenza koomatshini, njengovavanyo lokuqina, uvavanyo lwetorque, njl.njl., Ukuqinisekisa ukuba imveliso idibana neshishini kunye nemigangatho yabathengi)

Iithagethi ze-Molybdenum ziqhele ukusetyenziswa kwiityhubhu ze-X-reyi kumfanekiso wezonyango, uhlolo lwemizi-mveliso, kunye nophando lwezenzululwazi. Izicelo zeethagethi ze-molybdenum ikakhulu kukuvelisa ii-X-reyi zamandla aphezulu kumfanekiso wokuxilonga, njenge-computed tomography (CT) scans kunye ne-radiography.

Iithagethi zeMolybdenum zithandwa kwindawo yazo ephezulu yokunyibilika, ezivumela ukuba zimelane nobushushu obuphezulu obuveliswa ngexesha lemveliso yeX-ray. Kwakhona bane-conductivity efanelekileyo ye-thermal, inceda ukukhupha ukushisa kunye nokwandisa ubomi betyhubhu ye-X-ray.

Ukongeza kwi-imaging yonyango, iithagethi ze-molybdenum zisetyenziselwa uvavanyo olungonakalisi kwizicelo zoshishino, ezifana nokuhlola i-welds, imibhobho kunye nezixhobo ze-aerospace. Zikwasetyenziswa kwizibonelelo zophando ezisebenzisa i-X-ray fluorescence (XRF) spectroscopy kuhlalutyo lwezinto kunye nokuchongwa kwe-elemental.

Ukudibanisa izikrufu kunye namantongomane kubandakanya ukuqinisekisa ukuba imisonto yezikrufu kunye namantongomane iyahambelana. Nanga amanyathelo aqhelekileyo okudibanisa izikrufu kunye namandongomane:

1. Qinisekisa ubungakanani be-screw: Ukulinganisa ububanzi kunye nobude be-screw ukujonga ubungakanani baso. Ubukhulu bezijija eziqhelekileyo bonyulwa kusetyenziswa inani elilandelwa liqhezu, njenge #8-32 okanye #10-24.

2. Chonga iindidi zemisonto: Izikrufu kunye namandongomane zinokuba neendidi ezahlukeneyo zemisonto, njengemisonto erhabaxa okanye imisonto ecolekileyo. Kubalulekile ukuba uhlobo lwentambo ye-screw luhambelana ne-nut ehambelanayo.

3. Jonga i-pitch ye-thread pitch: I-pitch ye-thread pitch ibhekiselele kumgama phakathi kwemisonto ekufutshane kwi-screw okanye i-nut. Qinisekisa ukuba izikrufu kunye namandongomane anepitch yomsonto efanayo ukuqinisekisa ukuba zidibana ngokuchanekileyo.

4. Qwalasela imathiriyeli kunye namandla: Khetha izikrufu kunye namandongomane enziwe ngezinto ezihambelanayo kunye nemilinganiselo yamandla afanayo ukuqinisekisa ukuba banokumelana nesicelo esicetywayo.

5. Vavanya ukufaneleka: Ngaphambi kokhetho lokugqibela, vavanya izikrufu kunye namandongomane ukuze uqinisekise ukuba ziyahambelana kakuhle kwaye zikhuselekile.

Ngokulandela la manyathelo angezantsi, unokuthelekisa ngokufanelekileyo izikrufu kunye namandongomane kwisicelo sakho esithile.

Xa ucinga ngoyilo lwentambo yeebholiti ze-tantalum kunye namantongomane, kukho imiba emininzi ebalulekileyo ekufuneka iqatshelwe ngenxa yeempawu ezizodwa ze-tantalum:

1. I-Material Compatibility: I-Tantalum yintsimbi enganyangekiyo kwi-corrosion, ngoko ke kubalulekile ukuqinisekisa ukuba izinto ezisetyenziselwa amantongomane kunye neebholiti nazo ziyahambelana ne-tantalum. Ukusebenzisa izinto ezingahambelaniyo ne-tantalum kunokubangela ukubola kwe-galvanic kwaye kuphazamise ingqibelelo yokudibanisa.

2. I-Thread lubrication: I-Tantalum inomkhuba wokunxiba, okuyinkqubo yokubambelela kwizinto eziphathekayo kunye nokudluliselwa phakathi kweendawo zokutyibilika. Ukunciphisa le ngxaki, i-lubrication yentambo efanelekileyo kufuneka ithathelwe ingqalelo xa uyila iibholiti ze-tantalum kunye namantongomane ukuthintela ukunxiba kunye nokuqinisekisa ukudibanisa okugudileyo kunye nokuchithwa.

3. Amandla omsonto: I-Tantalum yintsimbi ethambileyo, ngoko amandla ezinto eziphathekayo kufuneka athathelwe ingqalelo xa kuyilwa imisonto. Kubalulekile ukuqinisekisa ukuba ifom yentambo kunye nokubandakanya inika amandla okwaneleyo kwisicelo esicetywayo ngelixa uphepha ukugxilwa koxinzelelo olugqithisileyo.

4. Ifom yomsonto: Ifom yomsonto, nokuba yi-metric, iyunifomu, okanye eminye imigangatho, kufuneka ikhethwe ngononophelo ukuqinisekisa ukuhambelana neendawo zokukhwela kunye nokuhlangabezana neemfuno ezithile zesicelo.

5. Umphezulu wokuGqibela: Iibholithi zeTantalum kunye namantongomane kufuneka zibe nomphezulu ogudileyo kunye nofanayo ukuze kuncitshiswe ukunxitywa okunokwenzeka kunye nokuqinisekisa ukutywinwa okufanelekileyo xa umdibaniso ubonakaliswe kulwelo okanye iigesi.

Ngokujongana nale miba kwi-tantalum bolt kunye noyilo lwentambo ye-nut, unokuqinisekisa ukuthembeka kunye nokusebenza kweenkqubo zakho zokuqinisa kwizicelo ze-tantalum.