ubushushu obuphezulu bokunyibilika kwe-molybdenum crucible kwiziko

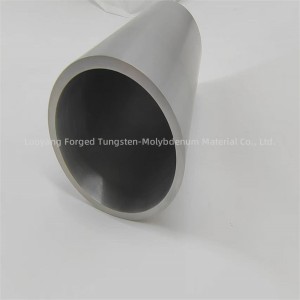

I-Molybdenum crucible yimveliso ebalulekileyo yemizi-mveliso esetyenziswa kakhulu kwishishini lesinyithi, ishishini lomhlaba elinqabileyo, isilicon ye-monocrystalline, i-crystal eyenziweyo kunye namashishini okulungisa oomatshini.

Ngokukodwa kwiziko lokukhula kwekristale enye, i-molybdenum crucibles enobunyulu obuphezulu, ukuxinana okuphezulu, akukho zintanda zangaphakathi, ubungakanani obuchanekileyo, kunye neendonga ezigudileyo zangaphakathi nangaphandle zidlala indima ebalulekileyo kwizinga lempumelelo ye-crystallization yembewu, ulawulo lomgangatho wokutsalwa kwekristale, de crystallization. kunye nokunamathela kwiimbiza, kunye nobomi benkonzo ngexesha lokukhula kwekristale yesafire. ...

| Imilinganiselo | Ukwenza ngokwezifiso |

| Indawo yeMvelaphi | Luoyang, Henan |

| Igama lebrand | FGD |

| Isicelo | Ishishini leMetallurgical |

| Ubume | Umjikelo |

| Umphezulu | Ilungisiwe |

| Ubunyulu | 99.95% Min |

| Izinto eziphathekayo | UMo emsulwa |

| Ukuxinana | 10.2g/cm3 |

| Iimpawu | Ukumelana nobushushu obuphezulu |

| Ukupakisha | Ityala lomthi |

| Amacandelo aphambili | Mo>99.95% |

| Umxholo wokungcola≤ | |

| Pb | 0.0005 |

| Fe | 0.0020 |

| S | 0.0050 |

| P | 0.0005 |

| C | 0.01 |

| Cr | 0.0010 |

| Al | 0.0015 |

| Cu | 0.0015 |

| K | 0.0080 |

| N | 0.003 |

| Sn | 0.0015 |

| Si | 0.0020 |

| Ca | 0.0015 |

| Na | 0.0020 |

| O | 0.008 |

| Ti | 0.0010 |

| Mg | 0.0010 |

| Izinto eziphathekayo | Uvavanyo lobushushu(℃) | Ukutyeba kwepleyiti(mm) | Unyango lwangaphambi kovavanyo lobushushu |

| Mo | 1100 | 1.5 | 1200℃/1h |

|

| 1450 | 2.0 | 1500℃/1h |

|

| 1800 | 6.0 | 1800℃/1h |

| I-TZM | 1100 | 1.5 | 1200℃/1h |

|

| 1450 | 1.5 | 1500℃/1h |

|

| 1800 | 3.5 | 1800℃/1h |

| MLR | 1100 | 1.5 | 1700℃/3h |

|

| 1450 | 1.0 | 1700℃/3h |

|

| 1800 | 1.0 | 1700℃/3h |

1. Umzi-mveliso wethu useLuoyang City, kwiPhondo laseHenan. I-Luoyang yindawo yemveliso yemigodi ye-tungsten kunye ne-molybdenum, ngoko ke sineenzuzo ezipheleleyo kumgangatho kunye nexabiso;

2. Inkampani yethu inabasebenzi bezobugcisa abaneminyaka engaphezu kwe-15 yamava, kwaye sibonelela ngezisombululo ezijoliswe kuzo kunye neengcebiso kwiimfuno zomthengi ngamnye.

3. Zonke iimveliso zethu zihlolwa ngokungqongqo umgangatho phambi kokuba zithunyelwe kumazwe angaphandle.

4. Ukuba ufumana iimpahla ezineziphene, unokuqhagamshelana nathi ukuze ubuyiselwe imali.

1. ukulungiswa kwezinto ekrwada

(Le mathiriyeli ekrwada idinga ukuhlangabezana nomgangatho othile wobunyulu, ngokuqhelekileyo kunye nemfuno yococeko ye-Mo ≥ 99.95%)

2. imveliso engenanto

(Layisha imathiriyeli ekrwada kumngundo ukuze ulungise i-billet eqinileyo yecylindrical, kwaye emva koko uyicinezele kwi-cylindrical billet)

3. umoni

(Beka indawo engenanto ecwangcisiweyo kwi-intermediate frequency sintering furnace, kwaye ungenise igesi yehydrogen kwiziko. Ubushushu bobushushu yi-1900 ℃ kwaye ixesha lokufudumeza ziiyure ezingama-30. Emva koko, sebenzisa ukujikeleza kwamanzi ukupholisa iiyure eziyi-9-10, kuphole ukuya ubushushu begumbi, kwaye ulungiselele umzimba obunjiweyo ukuze usetyenziswe kamva)

4. Ukubumba kunye nokubumba

(Fudumeza i-billet eyenziwe kwi-1600 ℃ kwiiyure ze-1-3, emva koko uyisuse kwaye uyifake kwi-crucible shape ukugqiba ukuveliswa kwe-molybdenum crucible)

Uphando lwezeNzululwazi: I-Molybdenum crucibles inoluhlu olubanzi lwezicelo kwinkalo yophando lwesayensi. Okokuqala, idlala indima ebalulekileyo kwiimvavanyo zemichiza, njengoko i-molybdenum crucibles isetyenziswa ngokubanzi kwiimvavanyo zokushisa okuphezulu kunye nokuphendula kweekhemikhali ngenxa yokuzinza kwazo okuphezulu kobushushu kunye nokuxhathisa ukubola. Kwisayensi yezinto, i-molybdenum crucibles isetyenziswa ngokubanzi kwiinkqubo ezinje ngokunyibilika kunye ne-slid-state sintering. Ngokomzekelo, kwinkqubo yokunyibilika kwee-alloys zetsimbi, i-molybdenum crucibles inokumelana nokushisa okuphezulu kunye nokugcina uzinzo, okwenza ukulungiswa kweentsimbi zetsimbi zichaneke kwaye zilawuleke.

Ukongeza, kuhlalutyo lwe-thermal kunye nokuvavanya ukusebenza kweesampuli zezinto eziphathekayo, i-molybdenum crucibles iphinda isebenze njengezikhongozelo ezibalulekileyo zesampula, inika indawo ezinzileyo kumaqondo okushisa aphezulu kunye nokuqinisekisa ukuchaneka kwedatha yovavanyo.

Ukusetyenziswa okungafanelekanga: Ukuba ukushisa kwehla ngokukhawuleza ngexesha lokusetyenziswa, uxinzelelo olubangelwa ukuhluka kweqondo lokushisa phakathi kweendonga zangaphandle kunye nezangaphakathi zidlula uluhlu olunokumelana ne-crucible, olunokuthi lukhokelela ekuqhekekeni. ...

Ewe, kunokwenzeka ukutshisa i-molybdenum crucible ukuya kushushu obomvu. IMolybdenum ineqondo eliphezulu lokunyibilika lama-2,623 degrees celsius (4,753 degrees Fahrenheit), nto leyo eyivumela ukuba imelane nobushushu obuphezulu kakhulu ngaphandle kokunyibilika. Oku kwenza i-molybdenum crucibles ifaneleke kwizicelo ezifuna ukufudumeza kwiqondo lokushisa elibomvu-elishushu, njengokunyibilika kwesinyithi, iglasi, okanye ezinye iinkqubo zobushushu obuphezulu. Nangona kunjalo, kubalulekile ukuqinisekisa ukuba i-crucible isetyenziswe ngaphakathi kwinqanaba lobushushu elichaziweyo kunye nokuba kulandelwa amanyathelo afanelekileyo okhuseleko xa kusetyenziswa iibhola ezibomvu ezishushu.

Kubalulekile ukutshisa i-crucible ngobunono ngexesha lomzuzu wokuqala ukukhusela ukutshatyalaliswa kwe-thermal. Xa i-crucible ebandayo ibonakaliswe kumaqondo aphezulu kakhulu ngokukhawuleza, inokubangela ukwanda okungalinganiyo kunye noxinzelelo lwe-thermal, olunokubangela ukuba i-crucible iqhube okanye iqhube. Ukunciphisa umngcipheko wokutshitshiswa kwe-thermal kwaye uqinisekise ukunyaniseka kwe-crucible ngexesha lokufudumeza ngokufudumeza i-crucible ngobunono ekuqaleni kwaye ngokuthe ngcembe uyizise kwiqondo lokushisa elifunayo. Le ndlela inceda ukwandisa ubomi be-crucible kwaye igcine ingqibelelo yayo yesakhiwo ukuze isetyenziswe kwakhona.