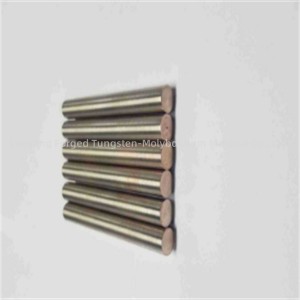

High Hardness Tungsten tooj liab Alloy Round Qws

Kev tsim cov tungsten tooj liab alloy round rods feem ntau yuav tsum tau ua tib zoo txheej txheem los xyuas kom meej cov khoom tsim nyog tau ua tiav. Hauv qab no yog cov kauj ruam dav dav rau kev tsim cov tungsten tooj liab alloy round rods:

Cov khoom siv raw xaiv: High-purity tungsten hmoov thiab tooj liab hmoov raug xaiv los ua cov ntaub ntawv tseem ceeb ntawm cov hlau. Kev xaiv ntawm cov ntaub ntawv raw yog qhov tseem ceeb rau kev ua tiav cov khoom tsim nyog, thermal thiab hluav taws xob ntawm cov khoom kawg. Powder Mixing: Tungsten hmoov thiab tooj liab hmoov yog sib xyaw kom huv si hauv kev tswj cov proportions kom tau txais qhov xav tau alloy muaj pes tsawg leeg. Cov kauj ruam sib xyaw no yog qhov tseem ceeb kom ntseeg tau tias muaj kev faib tawm ntawm cov khoom xyaw hauv cov hlau. Compaction: Cov hmoov sib xyaw yog compacted nyob rau hauv siab siab los tsim ib lub cev ntsuab nrog rau cov duab uas xav tau. Qhov briquetting no yog thawj kauj ruam hauv kev tsim cov khoom siv raw rau hauv cov pas nrig uas xav tau. Sintering: Lub cev ntsuab yog ces sintered ntawm qhov kub thiab txias nyob rau hauv ib qho chaw tswj kom sib txuas cov tungsten thiab tooj liab hais thiab ua tiav qhov yuav tsum tau ceev thiab txhua yam muaj zog. Thermal processing: Cov khoom siv sintered yog raug rau cov txheej txheem thermal xws li extrusion lossis forging kom ntxiv cov duab thiab ua kom cov khoom ua kom zoo nkauj rau hauv ib puag ncig qws. Kev kho cua sov: Qws Tshuag tuaj yeem dhau los ua cov txheej txheem kho cua sov los txhim kho nws cov khoom siv xws li lub zog thiab tawv. Kev Tswjhwm Zoo: Thaum lub sijhawm tag nrho cov txheej txheem tsim khoom, kev tswj xyuas zoo tau txais kev pom zoo los xyuas kom meej tias cov khoom muaj pes tsawg leeg, qhov loj thiab cov khoom siv ntawm cov khoom tau txais tungsten tooj liab alloy round rods ua tau raws li qhov yuav tsum tau ua.

Los ntawm kev ua raws li cov kauj ruam no, cov tuam txhab tsim khoom tuaj yeem tsim cov tungsten tooj liab alloy round rods nrog cov khoom xav tau, ua rau lawv tsim nyog rau ntau yam kev lag luam.

Tungsten tooj liab alloy round rods yog dav siv nyob rau hauv ntau yam teb vim hais tias ntawm lawv cov yam ntxwv tshwj xeeb. Nov yog qee qhov kev siv rau tungsten tooj liab alloy round rods:

Hluav taws xob thiab Thermal Conductivity: Tungsten tooj liab alloy round rods yog siv nyob rau hauv daim ntawv thov uas yuav tsum tau thermal thiab hluav taws xob conductivity, xws li hluav taws xob tiv tauj, tshav kub dab dej, thiab hluav taws xob paug machining (EDM) electrodes. High-temperature applications: Lub siab melting point thiab zoo heev thermal conductivity ntawm tungsten-tooj liab alloy ua rau nws haum rau siv nyob rau hauv high-kub ib puag ncig, xws li aerospace thiab tiv thaiv daim ntaub ntawv, rau cov khoom xws li foob pob ua ntxaij nozzles thiab high-temperature furnace Cheebtsam. Hnav tsis kam: Tungsten tooj liab alloy round rods yog siv rau hauv daim ntawv thov uas yuav tsum tau hnav tsis kam, xws li kev tsim cov vuam electrodes, hluav taws xob tiv tauj thiab yas pwm qhov chaw. Radiation Shielding: Tungsten-tooj liab alloy lub siab ceev thiab zoo heev hluav taws xob shielding zog ua rau nws haum rau kev kho mob thiab nuclear daim ntaub ntawv, xws li hluav taws xob kho cov cuab yeej thiab hluav taws xob shielding Cheebtsam. Aerospace thiab Kws muaj txuj ci: Tungsten tooj liab alloy round rods yog siv nyob rau hauv aerospace thiab tiv thaiv daim ntaub ntawv vim lawv lub zog siab, thermal stability thiab muaj peev xwm tiv taus huab cua txias, ua rau lawv haum rau cov khoom xws li propellant chambers, rotor hniav thiab armor-piercing projectiles.

Zuag qhia tag nrho, qhov tshwj xeeb ua ke ntawm cov khoom nthuav tawm los ntawm tungsten-tooj liab alloy round rods ua rau lawv muaj txiaj ntsig rau ntau yam kev siv hauv aerospace, tiv thaiv, hluav taws xob, thiab kev lag luam tsim khoom.

| Khoom npe | Tungsten Copper Alloy Round Qws |

| Khoom siv | W1 |

| Specification | Customized |

| Nto | Cov tawv nqaij dub, alkali ntxuav, polished. |

| Cov txheej txheem | Sintering txheej txheem, machining |

| Meltng point | 3400 ℃ |

| Qhov ntom | 19.3g / cm3 |

Wechat: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com