Molybdenum wafer molybdenum pob zeb diamond ntawv hauv CVD

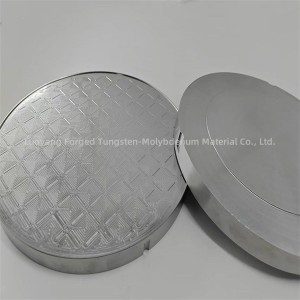

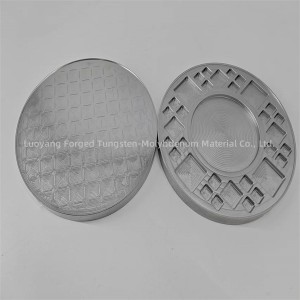

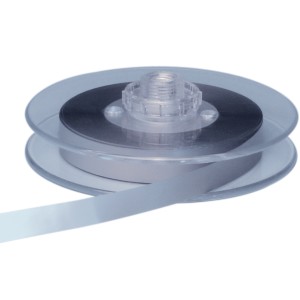

Cov tshuaj vapor deposition (CVD) txoj kev ntawm pob zeb diamond siv cov txheej txheem tshuaj los ua kom cov pob zeb diamond zaj duab xis los yog txheej hauv ib puag ncig tswj. Hauv cov qauv no, cov roj sib tov, feem ntau muaj cov pa roj carbon monoxide xws li methane, tau nkag mus rau hauv cov tshuaj tiv thaiv chav ua ke nrog cov khoom siv substrate xws li molybdenum wafers lossis pob zeb diamond wafers. Tom qab ntawd cov pa roj tau qhib los ntawm ntau txoj kev, xws li cua sov lossis ntshav, txhawm rau rhuav tshem cov pa roj carbon monoxide thiab tso cov pa roj carbon atoms mus rau hauv lub substrate, uas ua rau muaj kev loj hlob ntawm pob zeb diamond muaju.

Cov txheej txheem CVD ntawm pob zeb diamond muaj ntau qhov zoo, suav nrog lub peev xwm los tsim cov pob zeb zoo nkauj zoo nkauj nrog kev tswj xyuas meej ntawm thickness, uniformity thiab muaj pes tsawg leeg. Nws tseem tso cai rau kev tso cov pob zeb diamond films rau ntau yam khoom siv substrate, ua kom muaj cov pob zeb diamond-coated qhov chaw rau ntau yam kev lag luam thiab kev tshawb fawb.

Zuag qhia tag nrho, CVD txoj kev ntawm pob zeb diamond yog ntau yam thiab siv cov txheej txheem los tsim cov pob zeb diamond hluavtaws thiab cov txheej txheem nrog cov khoom siv kho mob, ua rau lawv muaj txiaj ntsig hauv kev lag luam xws li hluav taws xob, cov cuab yeej txiav, thiab cov txheej txheem hnav-tiv taus.

Lub hardness ntawm tshuaj vapor deposition (CVD) coatings yuav txawv nyob ntawm seb cov ntaub ntawv tshwj xeeb tso thiab cov txheej txheem tsis siv. Txawm li cas los xij, CVD txheej yog paub txog lawv qhov tshwj xeeb hardness, feem ntau dhau ntawm cov txheej txheem ntawm lub cev vapor deposition (PVD).

Rau pob zeb diamond CVD coatings, hardness yog tshwj xeeb yog noteworthy. Pob zeb diamond yog ib qho ntawm cov ntaub ntawv nyuaj tshaj plaws paub, thiab CVD pob zeb diamond txheej muaj qhov tshwj xeeb hardness uas feem ntau tshaj li ntawm lwm hom txheej. Lub hardness ntawm CVD pob zeb diamond txheej yog feem ntau ntsuas siv Vickers hardness nplai thiab thaj tsam ntawm 8000 HV mus rau ntau tshaj 10000 HV, ua rau nws yog ib qho ntawm cov khoom siv tawv thiab hnav-resistant tshaj plaws.

Rau lwm cov CVD txheej, xws li carbide los yog nitride-raws li txheej, lub hardness kuj yuav siab, muab zoo heev hnav kuj thiab durability nyob rau hauv ntau yam kev lag luam daim ntaub ntawv.

Zuag qhia tag nrho, CVD coatings muaj nuj nqis rau lawv qhov tshwj xeeb hardness, ua rau lawv tsim nyog rau cov ntawv thov uas hnav tsis kam, qhov kub thiab txias, thiab kev ua haujlwm ntev yog qhov tseem ceeb.

Wechat: 15138768150

WhatsApp: +86 15838517324

E-mail : jiajia@forgedmoly.com