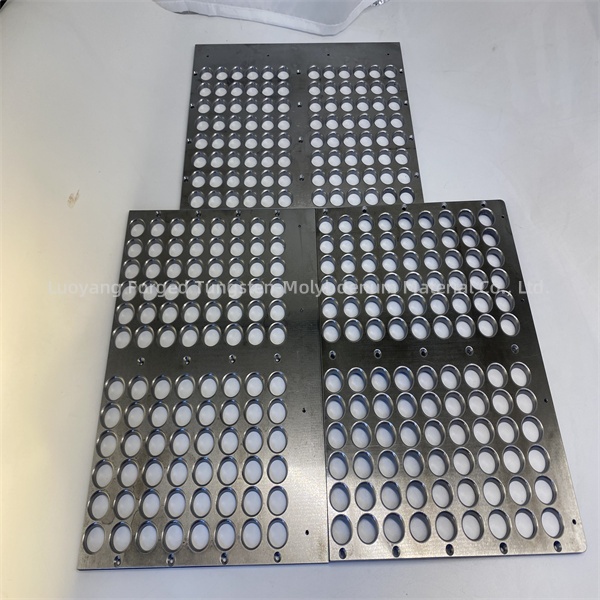

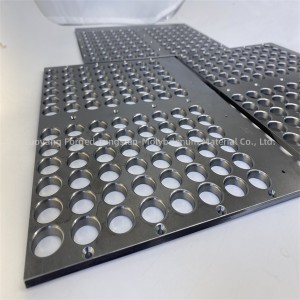

99.95 ntshiab corrosion tiv thaiv Perforated hlau molybdenum phaj

Ua ntej, molybdenum phaj txiav yog thawj kauj ruam hauv molybdenum phaj ua, thiab feem ntau siv txoj kev txiav suav nrog kev txiav tshuab, nplaim taws txiav, thiab txiav ntshav. Mechanical txiav yog cov txheej txheem ntawm kev txiav molybdenum daim hlau siv cov cuab yeej siv tshuab, feem ntau siv cov cuab yeej xws li shearing tshuab, xuas nrig ntaus tshuab, thiab lwm yam. Haum rau cov tuab molybdenum daim hlau. Plasma txiav yog cov txheej txheem ntawm kev txiav molybdenum daim hlau siv high-temperature plasma arcs, haum rau thinner molybdenum daim hlau.

Qhov thib ob, xuas nrig ntaus yog cov txheej txheem ntawm machining lub qhov nyob rau hauv txoj hauj lwm xaiv ntawm molybdenum phaj. Cov kev siv xuas nrig ntaus muaj xws li xuas nrig ntaus thiab laser xuas nrig ntaus. Punching yog txheej txheem ntawm xuas nrig ntaus thiab shearing qhov ntawm molybdenum daim hlau siv cov cuab yeej xuas nrig ntaus, haum rau cov kab loj dua. Laser xuas nrig ntaus yog cov txheej txheem ntawm kev ua molybdenum daim hlau los ntawm lasers, haum rau me me txoj kab uas hla qhov thiab complex zoo li lub qhov.

Perforated molybdenum nplooj ntawv muaj ntau yam khoom uas ua rau lawv haum rau ntau yam kev lag luam:

1. Qhov kub thiab txias tsis kam: Molybdenum muaj qhov siab melting point, thiab perforated molybdenum daim hlau tuaj yeem tiv taus qhov kub thiab txias, ua rau lawv haum rau kev siv nyob rau hauv high-temperature ib puag ncig, xws li cub tawg thiab aerospace kev siv.

2. Corrosion resistance: Molybdenum muaj kev tiv thaiv corrosion zoo heev, uas yog qhov zoo rau cov ntawv thov uas yuav tsum tau raug rau cov tshuaj hnyav los yog corrosive ib puag ncig.

3. Lub zog thiab durability: Perforated molybdenum panels tswj lub cev muaj zog thiab durability ntawm molybdenum, cia nws tiv taus txhua yam kev ntxhov siab thiab tswj cov qauv kev ncaj ncees nyob rau hauv hnyav hnyav.

4. Perforation yooj: Perforations nyob rau hauv molybdenum daim hlau tuaj yeem hloov kho kom tau raws li qhov tshwj xeeb airflow, pom lossis sib cais, muab ntau yam hauv ntau hom kev siv.

5. Thermal conductivity: Molybdenum muaj thermal conductivity zoo, thiab cov perforated molybdenum phaj tuaj yeem txhawb kev hloov hluav taws xob zoo, ua rau nws tsim nyog rau kev tswj xyuas thermal.

Cov khoom no ua rau cov nplooj ntawv molybdenum perforated muaj txiaj ntsig zoo rau cov ntawv thov uas xav tau qhov kub thiab txias, tiv thaiv corrosion, lub zog thiab cov qauv perforation tshwj xeeb.

Wechat: 15138768150

WhatsApp: +86 15838517324

E-mail : jiajia@forgedmoly.com