Ukumelana nokushisa okuphezulu kwe-MLa Wire

Izinhlobo eziningi zezintambo zenzelwe ukumelana namazinga okushisa aphezulu, okuhlanganisa:

1. Ama-alloys asekelwe ku-nickel: Izintambo zokushisela ezisekelwe ku-nickel, njenge-Inconel ne-nichrome, zaziwa ngokumelana kwazo nezinga lokushisa eliphezulu futhi zivame ukusetshenziswa ezinhlelweni ezidinga ukumelana nokushisa, njengezinto zokushisisa nezithando zomlilo zezimboni.

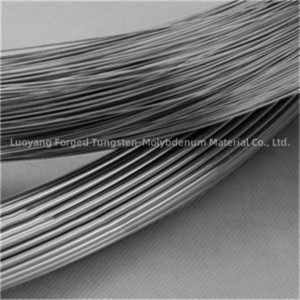

2. I-Tungsten: Intambo ye-Tungsten inephuzu lokuncibilika eliphezulu kakhulu futhi isetshenziswa ekusetshenzisweni kwezinga lokushisa eliphezulu njengamalambu okukhanya kwe-incandescent nezinto zokushisisa ezithandweni zokushisa okuphezulu.

3. I-Molybdenum: Intambo ye-Molybdenum nayo inendawo ephezulu yokuncibilika futhi isetshenziswa ezindaweni ezishisa kakhulu, okuhlanganisa izimboni ze-aerospace neze-electronics.

4. I-Platinum: Intambo ye-Platinum yaziwa ngokuzinza kwayo kwezinga lokushisa eliphezulu futhi isetshenziswa emishinini yaselabhorethri, ama-thermocouples nezinye izinhlelo zokusebenza zokushisa okuphezulu.

Lezi zintambo ziklanyelwe ngokukhethekile ukumelana nokushisa okukhulu futhi zisetshenziselwa izinhlelo zokusebenza ezihlukahlukene zezimboni, zesayensi nezobuchwepheshe ezidinga ukumelana nokushisa okuphezulu.

Ngokuvamile, intambo eshisayo inokumelana okuphakeme kunocingo olubandayo. Lokhu kungenxa yokuthi ukumelana kwezinto eziningi kukhula ngokushisa. Lobu budlelwano buchazwa yi-temperature coefficient of resistance, elinganisa ukuthi kungakanani ukumelana kwempahla kushintsha nezinga lokushisa.

Uma intambo ishisisiwe, amandla ashisayo anyukile abangela ama-athomu asendaweni ukuthi adlidlize ngamandla, okuholela ekungqubuzaneni okukhulu nokugeleza kwe-electron. Lokhu kudlidliza kwe-athomu okwandisiwe kuvimbela ukunyakaza kwama-electron, okubangela ukumelana okuphezulu nokugeleza kukagesi.

Ngokuphambene, njengoba ucingo luphola, ukuncipha kwamandla ashisayo kubangela ukuba ama-athomu aqhaqhazele kancane, ngaleyo ndlela kunciphisa ukumelana nokugeleza kukagesi.

Kuyaphawuleka ukuthi lobu buhlobo phakathi kwezinga lokushisa nokumelana akusebenzi kuzo zonke izinto, njengoba ezinye izinto zingase zibonise i-coefficient yokushisa engalungile yokumelana, okusho ukuthi ukumelana kwabo kuncipha njengoba izinga lokushisa likhuphuka. Kodwa-ke, ezintweni ezisetshenziswayo ezijwayelekile, okuhlanganisa izinsimbi ezifana nethusi ne-aluminium, ukumelana kuvame ukukhuphuka ngezinga lokushisa.

Uma izintambo zinokuphikiswa okuphezulu, imiphumela ehlukahlukene kanye nemiphumela ingenzeka, kuye ngokuthi isimo kanye nesicelo. Nayi eminye imiphumela evamile yezintambo eziqinile eziqinile:

1. Ukushisisa: Uma amandla kagesi edlula ocingweni olumelana kakhulu, kukhiqizwa inani elikhulu lokushisa. Lesi sakhiwo singasetshenziswa ekushisiseni izinto ezifana nalezo ezitholakala kuma-toaster, izitofu zikagesi kanye neziko lezimboni.

2. Ukwehla kwamandla kagesi: Kusekhethi, izintambo ezimelana kakhulu zingabangela ukwehla okukhulu kwamandla kagesi ngobude bocingo. Lokhu kungase kuthinte ukusebenza kwesifunda kanye nokusebenza kwemishini exhunyiwe.

3. Ukulahlekelwa kwamandla: Izintambo ezikwazi ukumelana kakhulu zenza amandla alahleke ngendlela yokushisa, okunciphisa ukusebenza kahle kwezinhlelo zikagesi kanye nemishini.

4. Ukwehliswa Kwamanje Kagesi: Izintambo ezikwazi ukumelana kakhulu zikhawulela ukuhamba kwamandla kagesi, okungase kuthinte ukusebenza kwemishini kagesi namasistimu, ikakhulukazi lawo adinga amazinga aphezulu amanje.

5. Ukushisa kwengxenye: Kumasekhethi e-elekthronikhi, ukuxhumeka okumelana kakhulu noma izingxenye kungabangela ukushisa kwendawo, okuthinta ukusebenza nokuthembeka kwesekethe.

Sekukonke, imiphumela yokumelana okuphezulu ezintanjeni incike kuhlelo lokusebenza oluthile kanye nomsebenzi ohlosiwe wezintambo ngaphakathi kwesistimu.

Ingxoxo: 15138768150

WhatsApp: +86 15138745597

E-mail : jiajia@forgedmoly.com