izinga lokushisa eliphezulu elincibilika i-molybdenum crucible yesithando somlilo

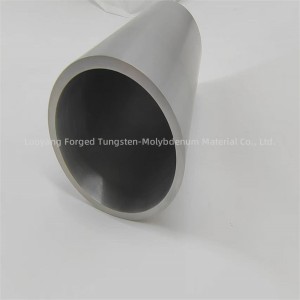

I-Molybdenum crucible ingumkhiqizo wezimboni obalulekile osetshenziswa kakhulu embonini ye-metallurgical, imboni yomhlaba engavamile, i-silicon ye-monocrystalline, i-crystal yokwenziwa kanye nezimboni zokucubungula imishini.

Ikakhulukazi ezifusini zokukhula zekristalu elilodwa, i-molybdenum crucible enobumsulwa obuphezulu, ukuminyana okuphezulu, akukho mifantu yangaphakathi, usayizi oqondile, nezindonga ezibushelelezi zangaphakathi nangaphandle zidlala indima ebalulekile ezingeni lempumelelo le-crystallization yembewu, ukulawula ikhwalithi yokudonsa ikristalu, i-crystallization. nokunamathela kwamabhodwe, nempilo yesevisi ngesikhathi sokukhula kwekristalu yesafire. .

| Ubukhulu | Ukwenza ngokwezifiso |

| Le yindawo ka Origin | Luoyang, Henan |

| I gama le-brand | FGD |

| Isicelo | Imboni yeMetallurgical |

| Isimo | Umjikelezo |

| Ubuso | Ipholishiwe |

| Ubumsulwa | 99.95% Min |

| Okubalulekile | Okuhlanzekile Mo |

| Ukuminyana | 10.2g/cm3 |

| Imininingwane | Ukumelana nokushisa okuphezulu |

| Ukupakisha | Ikesi Lokhuni |

| Izingxenye eziyinhloko | Mo>99.95% |

| Okuqukethwe ukungcola≤ | |

| Pb | 0.0005 |

| Fe | 0.0020 |

| S | 0.0050 |

| P | 0.0005 |

| C | 0.01 |

| Cr | 0.0010 |

| Al | 0.0015 |

| Cu | 0.0015 |

| K | 0.0080 |

| N | 0.003 |

| Sn | 0.0015 |

| Si | 0.0020 |

| Ca | 0.0015 |

| Na | 0.0020 |

| O | 0.008 |

| Ti | 0.0010 |

| Mg | 0.0010 |

| Okubalulekile | Hlola izinga lokushisa(℃) | Ukuqina Kwepuleti(mm) | Ukwelashwa kokushisa kwangaphambi kokuhlolwa |

| Mo | 1100 | 1.5 | 1200℃/1h |

|

| 1450 | 2.0 | 1500℃/1h |

|

| 1800 | 6.0 | 1800℃/1h |

| I-TZM | 1100 | 1.5 | 1200℃/1h |

|

| 1450 | 1.5 | 1500℃/1h |

|

| 1800 | 3.5 | 1800℃/1h |

| I-MLR | 1100 | 1.5 | 1700℃/3h |

|

| 1450 | 1.0 | 1700℃/3h |

|

| 1800 | 1.0 | 1700℃/3h |

1. Imboni yethu itholakala eLuoyang City, esifundazweni saseHenan. I-Luoyang iyindawo yokukhiqiza yezimayini ze-tungsten ne-molybdenum, ngakho-ke sinezinzuzo eziphelele ngekhwalithi namanani;

2. Inkampani yethu inabasebenzi bezobuchwepheshe abaneminyaka engaphezu kwengu-15 yesipiliyoni, futhi sinikeza izixazululo neziphakamiso ezihlosiwe zezidingo zekhasimende ngalinye.

3. Yonke imikhiqizo yethu ihlolwa ngokuqinile ikhwalithi ngaphambi kokuthunyelwa kwamanye amazwe.

4. Uma uthola izimpahla ezingalungile, ungaxhumana nathi ukuze uthole imbuyiselo.

1. ukulungiselela impahla eluhlaza

(Le nto eluhlaza idinga ukuhlangabezana nezinga elithile lokuhlanzeka, ngokuvamile nemfuneko yobumsulwa ye-Mo ≥ 99.95%)

2. ukukhiqizwa okungenalutho

(Layisha izinto zokusetshenziswa esikhunjini ukuze ulungise i-cylindrical billet eqinile, bese uyicindezela ibe yi-cylindrical billet)

3. umoni

(Beka okungenalutho okucutshungulwe esithandweni somlilo esiphakathi, bese ufaka igesi ye-hydrogen esithandweni. Izinga lokushisa lokufudumala lingu-1900 ℃ futhi isikhathi sokushisa amahora angu-30. Ngemva kwalokho, sebenzisa ukujikeleza kwamanzi ukuze uphole amahora angu-9-10, upholile izinga lokushisa legumbi, futhi ulungise umzimba obunjiwe ukuze usetshenziswe kamuva)

4. Ukuqamba nokubumba

(Shisisa i-billet eyakhiwe ibe ngu-1600 ℃ amahora angu-1-3, bese uyisusa futhi uyifake esimweni esibucayi ukuze uqedele ukukhiqizwa kwe-molybdenum crucible)

Ucwaningo lwesayensi: I-Molybdenum crucibles inohlu olubanzi lwezinhlelo zokusebenza emkhakheni wocwaningo lwesayensi. Okokuqala, idlala indima ebalulekile ekuhlolweni kwamakhemikhali, njengoba ama-molybdenum crucibles asetshenziswa kakhulu ekuhloleni izinga lokushisa eliphezulu kanye nokusabela kwamakhemikhali ngenxa yokuzinza kwawo okuhle kakhulu kwezinga lokushisa nokumelana nokugqwala. Kusayensi yezinto zokwakha, ama-molybdenum crucibles asetshenziswa kakhulu ezinqubweni ezinjengokuncibilika kanye ne-solid-state sintering. Isibonelo, ekuncibilikeni kwama-alloys ensimbi, ama-molybdenum crucibles angakwazi ukumelana namazinga okushisa aphezulu futhi alondoloze ukuzinza, okwenza ukulungiswa kwama-alloys ensimbi kucace futhi kulawuleke.

Ngaphezu kwalokho, ekuhlaziyweni okushisayo nokuhlolwa kokusebenza kwamasampula ezinto ezibonakalayo, ama-molybdenum crucibles nawo asebenza njengeziqukathi zesampula ezibalulekile, ezihlinzeka ngendawo ezinzile emazingeni okushisa aphezulu kanye nokuqinisekisa ukunemba kwedatha yokuhlola.

Ukusetshenziswa okungalungile: Uma izinga lokushisa lehla ngokushesha ngesikhathi sokusetshenziswa, ukucindezeleka okubangelwa umehluko wokushisa phakathi kwezindonga zangaphandle nezangaphakathi zidlula ububanzi obungamelana ne-crucible, okungase futhi kuholele ekuqhekekeni. .

Yebo, kungenzeka ukushisisa i-molybdenum crucible kuya ekushiseni okubomvu. I-Molybdenum inezinga eliphezulu lokuncibilika elingu-2,623 degrees Celsius (4,753 degrees Fahrenheit), okuyivumela ukuba imelane namazinga okushisa aphakeme kakhulu ngaphandle kokuncibilika. Lokhu kwenza ama-crucibles e-molybdenum alungele izinhlelo zokusebenza ezidinga ukushisisa kuya kumazinga okushisa abomvu-okushisa, njengokuncibilika kwezinsimbi, ingilazi, noma ezinye izinqubo zezinga lokushisa eliphezulu. Kodwa-ke, kubalulekile ukuqinisekisa ukuthi i-crucible isetshenziswa ngaphakathi kwebanga layo lokushisa elishiwo nokuthi izinyathelo ezifanele zokuphepha zilandelwa lapho kusetshenziswa iziphambano ezibomvu ezishisayo.

Kubalulekile ukushisa i-crucible ngobumnene phakathi nomzuzu wokuqala ukuvimbela ukushaqeka okushisayo. Uma i-crucible ebandayo ivezwa emazingeni okushisa aphezulu kakhulu ngokushesha, ingabangela ukwanda okungalingani kanye nokucindezeleka okushisayo, okungabangela ukuthi i-crucible iqhekeke noma iqhekeke. Nciphisa ubungozi bokushaqeka okushisayo futhi uqinisekise ubuqotho be-crucible ngesikhathi sokushisa ngokushisa i-crucible ngobumnene ekuqaleni futhi kancane kancane ukulethe ezingeni lokushisa elifunayo. Le ndlela isiza ukunweba impilo ye-crucible futhi igcine ubuqotho bayo besakhiwo ukuze iphinde isetshenziswe.