Ukuqina okuphezulu kwe-Tungsten yobhedu ye-Alloy Round Rod

Ukuveliswa kwee-tungsten copper alloy round rods ngokuqhelekileyo kufuna inkqubo ecokisekileyo yokuqinisekisa ukuba izinto ezifunekayo eziphathekayo ziyafezekiswa. Oku kulandelayo ngamanyathelo ngokubanzi okwenziwa kweentonga ezingqukuva ze-tungsten copper alloy:

Ukukhethwa kwezinto eziluhlaza: I-high-purity tungsten powder kunye ne-copper powder zikhethwa njengezona zixhobo eziphambili ze-alloy. Ukukhethwa kwezi zixhobo zekrwada kubaluleke kakhulu ekufezekiseni izinto ezifunekayo zomatshini, ezishushu kunye nezombane zemveliso yokugqibela. Ukuxutywa kwePowder: I-tungsten powder kunye nomgubo wobhedu zixutywe ngokucokisekileyo ngokwemilinganiselo elawulwayo ukuze kufumaneke ukubunjwa kwe-alloy oyifunayo. Eli nyathelo lokuxuba libalulekile ukuqinisekisa ukusasazwa ngokulinganayo kwezithako ngaphakathi kwe-alloy. I-Compaction: I-powder edibeneyo ihlanganiswe phantsi koxinzelelo oluphezulu ukwenza umzimba oluhlaza kunye nesimo esifunwayo. Le briquetting linyathelo lokuqala ekubumbeni imathiriyeli ekrwada kwimilo yentonga efunwayo. I-Sintering: Umzimba ohlaza emva koko u-sintered kwiqondo lokushisa eliphezulu kwi-atmosphere elawulwayo ukuze udibanise i-tungsten kunye neengqungquthela zobhedu kwaye ufezekise ubuninzi obufunekayo kunye namandla omatshini. Ukucutshungulwa kwe-Thermal: I-sintered material ixhomekeke kwiinkqubo ze-thermal processing ezifana ne-extrusion okanye i-forging ukuqhubela phambili ukubunjwa kunye nokucokisa izinto kwimilo yentonga ejikelezayo. Unyango lobushushu: Isitokhwe sentonga sinokungena kwinkqubo yonyango lobushushu ukuze siphucule iipropathi zayo zomatshini ezinje ngamandla kunye nokuqina. Ukulawulwa komgangatho: Ngexesha lenkqubo yonke yokuvelisa, amanyathelo okulawula umgangatho amkelwa ukuqinisekisa ukuba ukubunjwa, ubungakanani kunye neempawu zomatshini ze-tungsten copper alloy round rods ezifunyenweyo zihlangabezana neemfuno ezichaziweyo.

Ngokulandela la manyathelo okuvelisa, abavelisi banokuvelisa i-tungsten copper alloy round rods kunye neempawu ezifunwayo, okwenza ukuba zilungele uluhlu olubanzi lwezicelo zoshishino.

I-tungsten copper alloy rods isetyenziswa ngokubanzi kwiinkalo ezahlukeneyo ngenxa yeempawu zabo ezizodwa. Nazi ezinye iindlela eziqhelekileyo zokusetyenziswa kweentonga ze-tungsten copper alloy round:

Ukuqhuba koMbane kunye neThermal: I-tungsten copper alloy round rods isetyenziselwa izicelo ezifuna ukuhanjiswa kombane ophezulu kunye nombane, ezifana noqhagamshelwano lombane, i-heat sinks, kunye ne-electrodes yokukhutshwa kombane (EDM). Ukusetyenziswa kobushushu obuphezulu: Iqondo eliphezulu lokunyibilika kunye ne-thermal conductivity egqwesileyo ye-tungsten-copper alloy yenza ukuba ilungele ukusetyenziswa kwiindawo eziphakamileyo zokushisa, ezifana ne-aerospace kunye nezicelo zokukhusela, kumacandelo afana ne-rocket nozzles kunye nezixhobo zokushisa eziphezulu zokushisa. Ukumelana nokunxiba: I-Tungsten copper alloy round rods isetyenziswa kwizicelo ezifuna ukumelana nokunxiba okuphezulu, njengokwenziwa kwee-electrode ze-welding, unxibelelwano lombane kunye neendawo zokubumba zeplastiki. Ukukhusela iRadiation Shielding: Ingxubevange ye-Tungsten-copper alloy ephezulu kunye neempawu ezibalaseleyo zokukhusela ukusasazeka kwemitha ziyenza ifanelekele izicelo zonyango nezenyukliya, ezifana nezixhobo zonyango lwemitha kunye namacandelo okukhusela ngemitha. I-Aerospace kunye noKhuseleko: I-tungsten copper alloy round rods isetyenziselwa kwi-aerospace kunye nezicelo zokukhusela ngenxa yamandla abo aphezulu, ukuzinza kwe-thermal kunye nokukwazi ukujamelana neemeko ezinzima, okwenza ukuba zilungele amacandelo afana namagumbi ajikelezayo, i-rotor blades kunye neeprojectiles zokubhoboza izixhobo.

Ngokubanzi, udibaniso olukhethekileyo lweepropati ezibonakaliswe yi-tungsten-copper alloy round rods zenza ukuba zixabiseke kuluhlu olubanzi lwezicelo kwi-aerospace, ukukhusela, i-electronics, kunye namashishini okuvelisa.

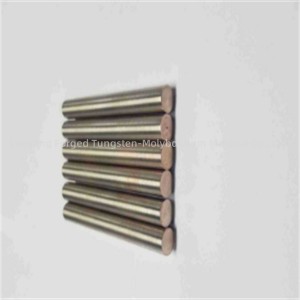

| Igama lemveliso | I-Tungsten Copper Alloy Round Rod |

| Izinto eziphathekayo | W1 |

| Inkcazo | Customized |

| Umphezulu | Ulusu olumnyama, ialkali ihlanjiwe, igudisiwe. |

| Ubuchwephesha | inkqubo Sintering, machining |

| Indawo yokunyibilika | 3400℃ |

| Ukuxinana | 19.3g/cm3 |

Wechat: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com