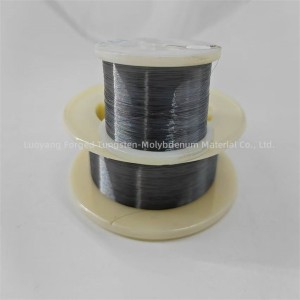

tungsten kunye nocingo molybdenum Evaporation iikhoyili

Tungsteniikhoyili zomphunga

Ubunyulu : W ≥ 99.95%

Iimeko zomphezulu : Ikhemikhali ecociweyo okanye i-electrolytic polishing.

Indawo yokunyibilika: 3420 ± 20 ℃

Ubungakanani : ngokomzobo onikiweyo.

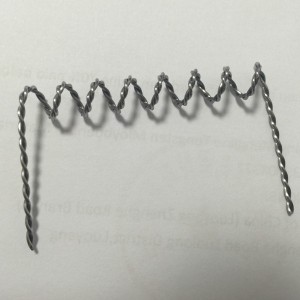

Uhlobo: Ngokuthe tye, imilo ye-U, imilo ye-V, iBasket.Helical.

Isicelo: Izifudumezi zocingo zeTungsten zisetyenziselwa ukufudumeza izinto ezinjengetyhubhu yemifanekiso, isibuko, iplastiki, i-metal substrate, i-ABS, i-PP kunye nezinye izinto zeplastiki kumphezulu wezinto ezahlukeneyo zokuhombisa. Intambo yeTungsten isetyenziswa ikakhulu njengento ekrwada yesifudumezi.

umgaqo wokusebenza: I-Tungsten inendawo ephezulu yokunyibilika, ukumelana nombane okuphezulu, amandla amahle kunye noxinzelelo lomphunga oluphantsi, iyenza ilungele ukusetyenziswa njengesifudumezi. I-membrane ifakwe kwi-heater kwigumbi lokucoca, kwaye ishushu phantsi kwemeko ephezulu yokucoca nge-heater (i-tungsten heater) ukuze ikhuphe. Xa indlela ekhululekileyo yeemolekyuli zomphunga inkulu kunomlinganiselo womgca wegumbi lokucoca, iiathomu zomphunga Emva kokuba iimolekyuli zibalekele kumphezulu womthombo wokuphuphuma komphunga, azifane zichaphazeleke okanye zithintelwe zezinye iimolekyuli okanye iiathomu, kwaye inokufikelela ngokuthe ngqo kumphezulu we-substrate ukuba ifakwe. Ngenxa yokushisa okuphantsi kwe-substrate, ifilimu yenziwe ngokuxinana.

I-Thermal evaporation (i-resistance evaporation) yindlela yokwaleka esetyenziswa njengenxalenye yenkqubo ye-PVD (i-Physical Vapor Deposition). Izinto eziza kwenza umaleko olandelayo zifudunyezwe kwigumbi levacuum de zibe ngumphunga. Umphunga owenziwe zizinto eziphathekayo udibanisa kwi-substrate kwaye wenze umaleko ofunekayo.

Iikhoyili zethu zokuba ngumphunga ziyakwazi ukubunyusa ubushushu: Ezi zifudumezi ezinganyangekiyo zineendawo zazo zokunyibilika eziphezulu kakhulu ziya kuzisa nasiphi na isinyithi ukuba sibile. Ngexesha elifanayo, ukuchasana kwabo okuphezulu kunye nokucoceka kwezinto ezibonakalayo kuthintela nakuphi na ukungcoliswa kwe-substrate.