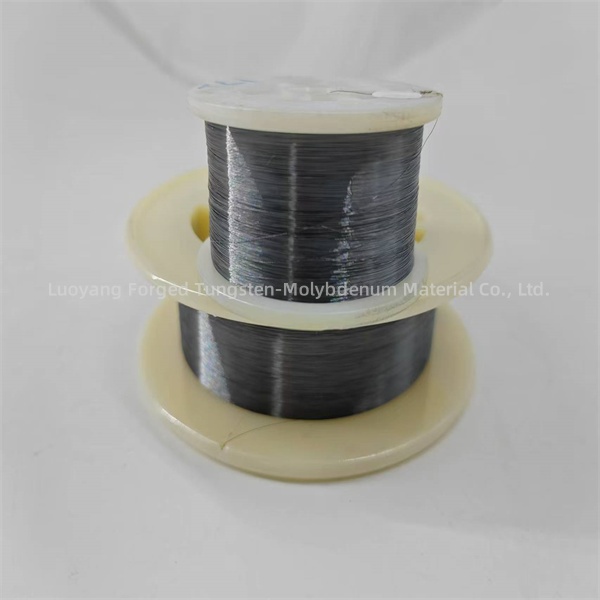

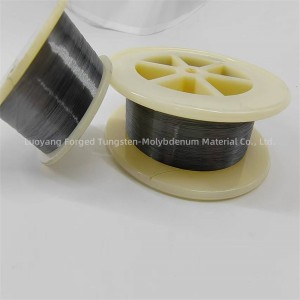

I-W1 ecocekileyo 0.18 i-tungsten wire EDM yokusika

Ewe, i-EDM yocingo (i-electrical discharge machining) ingasetyenziselwa ukusika i-tungsten. I-Tungsten yinto enzima, enyibilikayo ephezulu enokuba ngumceli mngeni ukuyisika usebenzisa iindlela zokulungisa zemveli. Nangona kunjalo, oomatshini bocingo be-EDM bafanelekile ukusika i-tungsten ngenxa yokukwazi ukusika ngokuchanekileyo imilo enzima kwizinto ezinzima.

Kwi-EDM yocingo, i-wire conductive wire (edla ngobhedu okanye i-tungsten) isetyenziselwa ukusika i-workpiece. Xa usika i-tungsten usebenzisa i-EDM yocingo, kubalulekile ukuqwalasela ezi zinto zilandelayo:

1. Ukukhetha ucingo: Ucingo lweTungsten lunokusetyenziswa njengocingo lokusika kwi-machining yokukhutshwa kombane ukusika izinto ezinzima ezifana ne-tungsten. Intambo yeTungsten yakhethwa ngenxa yokuqina kwayo okuphezulu kunye nokuchasana nobushushu kunye nokulimala.

2. Izicwangciso zamandla: Umshini wakho we-EDM kufuneka ubekwe kwiindawo ezifanelekileyo zamandla ukuqinisekisa ukukhutshwa kwezinto ezisebenzayo ngelixa ugcina ingqibelelo ye-tungsten filament.

3. Ukucoca kunye nokususa i-debris: Xa usika i-tungsten, ukucoca ngokufanelekileyo kunye nokususwa kwe-debris ye-workpiece kubalulekile ukugcina ukuchaneka kokusika kunye nokukhusela ukuphulwa kwentambo.

4. Uxinzelelo lwe-wire kunye ne-Treading: Ukunyanzeliswa okufanelekileyo kunye nokuxutywa kwentambo ye-tungsten kubalulekile ekufezekiseni iziphumo zokusika ezichanekileyo kunye nezihambelanayo.

Xa usika i-tungsten ngomshini we-EDM wocingo, kubalulekile ukulandela iindlela ezifanelekileyo kunye nokuqwalasela iimpawu ezithile ze-tungsten ukufezekisa iziphumo ezihle kakhulu zokusika.

Ubukhulu bocingo lwe-EDM (i-Electrical Discharge Machining) ukusika kunokwahluka ngokuxhomekeke kwisicelo esithile kunye nezinto ezicutshungulwayo. Ngokuqhelekileyo, i-EDM ye-wire diameter idla ngokuba yi-0.1 mm ukuya kwi-0.3 mm (0.004 intshi ukuya kwi-intshi ye-0.012). Nangona kunjalo, ucingo olungqingqwa okanye oluncinci lunokusetyenziswa kwizicelo ezithile.

Ngokusikeka okurhabaxa okanye ukususwa kwemathiriyeli ngokukhawuleza, iingcingo ezishinyeneyo (0.25 mm ukuya kwi-0.3 mm) zinokukhethwa. Ucingo olutyebileyo lunokuphatha imisinga ephezulu kwaye lungcono ukususwa kwezinto ngokukhawuleza.

Ukunqunyulwa okucokisekileyo, imilo enzima, okanye ukunyamezela okuqinileyo, iingcingo ezincinci (0.1 mm ukuya kwi-0.2 mm) zisetyenziswa ngokuqhelekileyo. I-Thinner wire ivumela ukusika okuchanekileyo kunye neenkcukacha, iyenze ilungele izicelo ezifuna ukuchaneka okuphezulu.

Xa ukhetha i-wire thickness for EDM cutting, izinto ezifana nezinto ezicutshungulwayo, isantya sokusika esifunekayo kunye nokugqitywa kwendawo efunekayo kufuneka kuthathelwe ingqalelo. Ukongezelela, izakhono ezithile zomshini we-EDM kunye neengcebiso zomenzi kufuneka ziqwalaselwe xa kuchongwa ubungakanani obufanelekileyo bocingo kwisicelo esinikezelweyo.

Wechat: 15138768150

WhatsApp: +86 15838517324

E-mail : jiajia@forgedmoly.com