likarolo tsa machining tsa molybdenum tse bentšitsoeng tsa Mo1 tse hloekileng tsa molybdenum karolo ea mochini

Ho hlahisa likarolo tsa mochini oa molybdenum hangata ho kenyelletsa mehato e mengata:

Khetho ea thepa: Molybdenum e fumaneha ka mefuta e fapaneng ea limaraka, ho kenyeletsoa pure molybdenum (Mo1) le li-alloys tsa molybdenum. Khetha boemo bo nepahetseng ho latela thepa e lakatsehang le ts'ebeliso ea karolo ea ho qetela. Machining: Molybdenum machining e kenyelletsa mekhoa e kang ho phethola, ho sila, ho cheka le ho sila. Ka lebaka la ho thatafala le brittleness ea thepa, lisebelisoa tse khethehileng le lisebelisoa li ka 'na tsa hlokahala bakeng sa ho sebetsa hantle. Tlhahiso: Kamora ho sebetsa ka mochini, likarolo tsa molybdenum li ka 'na tsa e-ba le mekhoa e meng ea tlhahiso e kang ho kobeha, ho etsa, kapa ho cheselletsa ho fumana sebopeho le tlhophiso e lakatsehang. Phekolo ea bokaholimo: Ts'ebetso ea kalafo ea bokaholimo joalo ka ho bentša, ho roala kapa kalafo ea mocheso e ka sebelisoa ho ntlafatsa bokaholimo ba bokaholimo, ho hanyetsa kutu kapa lisebelisoa tse ling tsa likarolo tsa molybdenum tse entsoeng ka mochini. Tlhahlobo le Taolo ea Boleng: Joalo ka ts'ebetso efe kapa efe ea tlhahiso, tlhahlobo e phethahetseng le mehato ea taolo ea boleng li bohlokoa ho netefatsa hore likarolo tse entsoeng ka mochini oa molybdenum li kopana le lintlha le litekanyetso tse hlokahalang.

Hobane molybdenum e na le thepa e ikhethang e kang sebaka se phahameng sa ho qhibiliha, matla a mocheso o phahameng, conductivity e ntle ea mocheso, le ho hanyetsa kutu, likarolo tse entsoeng ka molybdenum li na le mefuta e mengata ea lisebelisoa.

Lisebelisoa tse ling tse tloaelehileng bakeng sa likarolo tse entsoeng ka molybdenum li kenyelletsa: Sepakapaka le Tšireletso: Likarolo tsa Molybdenum li sebelisoa lits'ebetsong tsa lifofane le tsa sefofane tse kang li-rocket nozzles, likarolo tsa sebopeho le likarolo tsa enjene ea mocheso o phahameng. Li boetse li sebelisoa lisebelisoa tse amanang le ts'ireletso ka lebaka la matla a tsona a phahameng le ts'ebetso ea tsona maemong a feteletseng. Indasteri ea Elektronike le Semiconductor: Molybdenum e sebelisoa ha ho etsoa lisebelisoa tsa elektroniki, ho kenyeletsoa lipehelo tsa sputtering, likarolo tsa ho futhumatsa le likarolo tsa sebōpi. E boetse e sebelisoa tlhahisong ea semiconductor bakeng sa lits'ebetso tsa vacuum le ts'ebetso ea mocheso. Ho Qhibiliha ha Khalase le ho Etsa Likhalase: Likarolo tsa Molybdenum li sebelisoa indastering ea likhalase ka lebaka la bokhoni ba tsona ba ho mamella mocheso o phahameng le tikoloho e senyang e fumanoang litankang tse qhibilihang tsa khalase, li-electrode le phepelo ea lijo. Likarolo tsa Sebōpi sa Mocheso o Phahameng oa Mocheso: Likarolo tse entsoeng ka mochine oa Molybdenum li sebelisoa lits'ebetsong tsa sebōpi se phahameng sa mocheso tse kang lisebelisoa tsa ho futhumatsa, tšireletso ea mahlaseli le mehaho ea ts'ehetso ka lebaka la boemo ba eona bo phahameng ba ho qhibiliha le mocheso oa mocheso. Lisebelisoa tsa Bongaka le Liindasteri: Likarolo tsa Molybdenum li sebelisoa mefuteng e sa tšoaneng ea lisebelisoa tsa bongaka le tsa indasteri, ho kenyelletsa le li-tubes tsa X-ray, lisebelisoa tsa litšoantšo tsa bongaka le lisebelisoa tsa ho sebetsana le mocheso o phahameng oa mocheso, bakeng sa ho tšepahala le ho sebetsa ha bona libakeng tse thata. Indasteri ea Eneji: Molybdenum e sebelisoa indastering ea matla bakeng sa likarolo tsa phepelo ea matla, ho kenyeletsoa li-reactor tsa nyutlelie, lienjine tsa turbine le lisebelisoa tse ling tsa mocheso o phahameng le tse thibelang ho bola.

Ena ke mehlala e 'maloa feela ea lits'ebetso tse ngata tsa likarolo tsa mochini oa molybdenum. Thepa e ikhethang ea Molybdenum e etsa hore e loketse ho sebelisoa libakeng tse boima moo mocheso o phahameng, ho hanyetsa kutu le matla li leng bohlokoa.

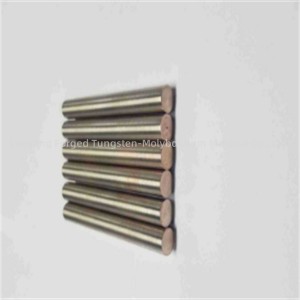

| Lebitso la Sehlahiswa | Likarolo tsa Molybdenum Maching |

| Lintho tse bonahalang | Mo1 |

| Tlhaloso | Customized |

| Bokaholimo | Letlalo le letšo, alkaline e hlatsoitsoe, e bentšitsoe. |

| Theknoloji | Sintering process, machining |

| Meltng point | 2600 ℃ |

| Botenya | 10.2g/cm3 |

Wechat: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com