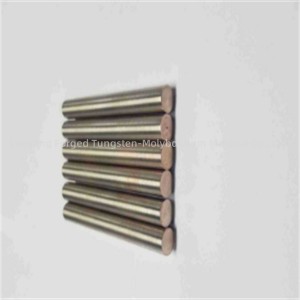

High Hardness Tungsten koporo Alloy Round Rod

Tlhahiso ea lithupa tse pota-potileng tsa koporo ea tungsten hangata e hloka ts'ebetso e hlokolosi ho netefatsa hore thepa e hlokahalang ea thepa e ea fihlelleha. Tse latelang ke mehato e akaretsang ea tlhahiso ea lithupa tse chitja tsa tungsten koporo:

Khetho ea thepa e tala: Phofo e phahameng ea tungsten le phofo ea koporo li khethoa e le lisebelisoa tse ka sehloohong tsa alloy. Khetho ea lisebelisoa tsena tse tala ke ea bohlokoa ho finyella thepa e hlokahalang ea mochine, mocheso le motlakase oa sehlahisoa sa ho qetela. Ho Kopanya Powder: Phofo ea Tungsten le phofo ea koporo li tsoakane ka botlalo ka tekanyo e laoloang ho fumana sebopeho se lakatsehang sa alloy. Mohato ona oa ho kopanya o bohlokoa ho etsa bonnete ba hore ho na le kabo e lekanang ea metsoako ka har'a motsoako. Compaction: Phofo e tsoakiloeng e kopantsoe tlas'a khatello e phahameng ho etsa 'mele o motala o nang le sebōpeho se batlang. Briquetting ena ke mohato oa pele oa ho bopa thepa e tala hore e be sebopeho sa molamu o lakatsehang. Sintering: 'Mele o motala o sintered ka mocheso o phahameng sebakeng se laoloang ho kopanya likaroloana tsa tungsten le koporo le ho finyella boima bo hlokahalang le matla a mochine. Thermal processing: Thepa ea sintered e tlas'a mekhoa ea ts'ebetso ea mocheso e kang extrusion kapa forging ho tsoela pele ho bōpa le ho hloekisa thepa hore e be sebopeho sa molamu o chitja. Kalafo ea Mocheso: Melamu e ka kena tšebetsong ea kalafo ea mocheso ho ntlafatsa thepa ea eona ea mochini joalo ka matla le boima. Taolo ea boleng: Nakong ea ts'ebetso eohle ea tlhahiso, mehato ea taolo ea boleng e amoheloa ho netefatsa hore sebopeho, boholo le thepa ea mochini ea lithupa tse pota-potileng tsa tungsten copper alloy li fihlela litlhoko tse boletsoeng.

Ka ho latela mehato ena ea tlhahiso, bahlahisi ba ka hlahisa lithupa tse pota-potileng tsa koporo ea tungsten ka thepa e lakatsehang, e leng se etsang hore e tšoanelehe bakeng sa mefuta e mengata ea lisebelisoa tsa indasteri.

Lithupa tse pota-potileng tsa koporo ea Tungsten li sebelisoa haholo libakeng tse fapaneng ka lebaka la thepa ea tsona e ikhethang. Mona ke lisebelisoa tse ling tse tloaelehileng bakeng sa lithupa tse pota-potileng tsa koporo ea tungsten:

Motlakase le Thermal Conductivity: Lithupa tse pota-potileng tsa koporo ea Tungsten li sebelisoa lits'ebetsong tse hlokang mocheso o phahameng oa mocheso le motlakase, joalo ka likhokahano tsa motlakase, licheso tsa mocheso, le li-electrode tsa machining tsa motlakase (EDM). Lisebelisoa tsa mocheso o phahameng: Sebaka se phahameng sa ho qhibiliha le mocheso o motle oa motlakase oa tungsten-copper alloy e etsa hore e tšoanelehe ho sebelisoa libakeng tse phahameng tsa mocheso, tse kang lisebelisoa tsa sefofane le tšireletso, bakeng sa likarolo tse kang li-nozzles tsa rocket le likarolo tsa sebōpi sa mocheso o phahameng. Khanyetso ea ho roala: Lithupa tse chitja tsa Tungsten tsa koporo li sebelisoa lits'ebetsong tse hlokang khanyetso e phahameng, joalo ka ho etsa li-electrode tsa welding, likhokahano tsa motlakase le likarolo tsa hlobo ea polasetiki. Radiation Shielding: Tlhekefetso e phahameng ea Tungsten-copper alloy le litšobotsi tse ntle tse sireletsang mahlaseli a kotsi li etsa hore e tšoanelehe bakeng sa ts'ebeliso ea bongaka le ea nyutlelie, joalo ka thepa ea kalafo ea radiation le likarolo tse sireletsang mahlaseli. Aerospace le Tšireletso: Lithupa tse pota-potileng tsa koporo ea Tungsten li sebelisoa sebakeng sa lifofane le lits'ebetsong tsa ts'ireletso ka lebaka la matla a tsona a phahameng, botsitso ba mocheso le bokhoni ba ho mamella maemo a feteletseng, ho etsa hore li tšoanelehe bakeng sa likarolo tse kang liphaposi tsa propellant, li-rotor blades le projectiles tse phunyeletsang lihlomo.

Ka kakaretso, motsoako o ikhethang oa thepa e bonts'itsoeng ke melamu e pota-potileng ea tungsten-copper alloy e etsa hore e be ea bohlokoa bakeng sa mefuta e mengata ea likopo tsa lifofane, ts'ireletso, lisebelisoa tsa elektronike le indasteri ea tlhahiso.

| Lebitso la Sehlahiswa | Tungsten Copper Alloy Round Rod |

| Lintho tse bonahalang | W1 |

| Tlhaloso | Customized |

| Bokaholimo | Letlalo le letšo, alkaline e hlatsoitsoe, e bentšitsoe. |

| Theknoloji | Sintering process, machining |

| Meltng point | 3400 ℃ |

| Botenya | 19.3g/cm3 |

Wechat: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com