Forged Molybdenum Alloys Hexagonal Molybdenum Nut M4 M5 M6

Mokhoa oa tlhahiso ea linate tsa hexagonal molybdenum hangata o kenyelletsa mehato e mengata ea bohlokoa:

Khetho ea lintho tse bonahalang: High-purity molybdenum e khethoa e le thepa e tala bakeng sa ho hlahisa linate. Molybdenum e sebelisitsoeng e lokela ho ba le sebopeho se nepahetseng sa lik'hemik'hale le lisebelisoa tsa mochini ho fihlela litlhoko tsa sehlahisoa sa ho qetela. Forging: Mohato oa pele hangata ke ho theha thepa ea molybdenum ho bareng kapa molamu oa hexagonal. Hangata sena se finyelloa ka mekhoa e kang ho fereka ho chesang, moo molybdenum e futhumatsoang ho fihlela mocheso o phahameng 'me e ntan'o bōptjoa ka ho sebelisa lesela kapa hamore ho fumana setšoantšo se lakatsehang sa hexagonal. Machining: The forged hexagonal molybdenum rod e ntan'o etsoa mochini ho ea ho litekanyo tse hlokahalang bakeng sa nate. Sena se ka kenyelletsa ts'ebetso ea ho phethola, ho sila kapa ho seha ho etsa sebopeho sa hexagonal le ho hlahisa likhoele tse hlokahalang le likarolo tse ling. Kalafo ea mocheso: Ka mor'a ho sebetsa, linate tsa molybdenum hexagon li ka kena ts'ebetsong ea phekolo ea mocheso ho ntlafatsa thepa ea thepa le ho matlafatsa matla a eona a mochine le litšobotsi tse ling. Taolo ea Boleng: Nakong eohle ea ts'ebetso ea tlhahiso, mehato e fapaneng ea taolo ea boleng e kengoa ts'ebetsong ho netefatsa hore linate tsa molybdenum li fihlela litlhoko tse boletsoeng bakeng sa litekanyo, mamello, thepa ea thepa le ts'ebetso. Ho Qetella Bokahohle: Ho ipapisitse le kopo le litlhoko tsa bareki, linate tsa molybdenum li ka kena lits'ebetsong tsa ho phethela bokaholimo joalo ka ho hloekisoa, ho belisoa, kapa ho roala ho ntlafatsa ponahalo ea tsona, ho hanyetsa kutu kapa thepa e meng ea ts'ebetso.

Ka kakaretso, mokhoa oa tlhahiso ea linate tsa hexagonal molybdenum li kenyelletsa letoto la mehato ea ho fetola thepa e tala ea molybdenum hore e be nate e phethiloeng ka sebōpeho, boholo le thepa e hlokahalang bakeng sa tšebeliso e reriloeng. Mohato o mong le o mong o hloka taolo e nepahetseng, e hlokolosi ho netefatsa boleng le botšepehi ba sehlahisoa sa ho qetela.

Hangata linate tsa hexagonal molybdenum li sebelisoa mochesong o phahameng le libakeng tse senyang moo linate tse tloaelehileng tsa tšepe li ka 'nang tsa se ke tsa tšoaneleha. E tsebahala ka ntlha ea eona e phahameng ea ho qhibiliha, matla le ho hanyetsa ho bola, tšebeliso ea molybdenum e etsa hore linate tsena li be ntle bakeng sa likopo liindastering tse kang sefofane, tšireletso le likoloi. Li etselitsoe ka ho khetheha hore li mamelle mocheso o feteletseng 'me li loketse ho sebelisoa lienjineng, li-turbine le lisebelisoa tse ling tsa mocheso o phahameng. Ho feta moo, khanyetso ea tsona ea kutu e etsa hore e be ea bohlokoa ts'ebetsong ea lik'hemik'hale moo ho kopanang khafetsa le lisebelisoa tse senyang. Sebopeho sa hexagonal se lumella ho kenya le ho tlosoa habonolo ho sebelisa lisebelisoa tse tloaelehileng, ho fana ka tharollo e sireletsehileng le e sireletsehileng ea ho tiisa. Hangata linate tsena li sebelisoa hammoho le liboutu tsa molybdenum, li-studs, kapa li-fasteners tse ling ho boloka likarolo le meaho libakeng tse thata.

Ka kakaretso, ts'ebeliso ea linate tsa hexagonal molybdenum e bohlokoa lits'ebetsong moo mocheso o phahameng, kutu le khatello ea mochini li hlokang tharollo e tšoarellang le e tšepahalang ea ho tiisa.

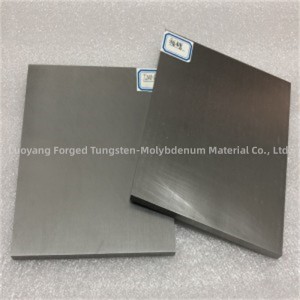

| Lebitso la Sehlahiswa | Hexagonal Molybdenum Nut |

| Lintho tse bonahalang | Mo1 |

| Tlhaloso | Customized |

| Bokaholimo | Letlalo le letšo, alkaline e hlatsoitsoe, e bentšitsoe. |

| Theknoloji | Sintering process, machining |

| Meltng point | 2600 ℃ |

| Botenya | 10.2g/cm3 |

Wechat: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com