molybdenum selikalikoe molybdenum chitja molybdenum machined karolo

E, molybdenum e nkoa e le thepa e thata ho e khaola ka lebaka la ho thatafala ha eona le ho thatafala ha eona. Ho thatafala ha eona le ho hanyetsa deformation ho etsa hore ho be thata ho mochine o sebelisa lisebelisoa le mekhoa ea ho itšeha ea setso. Ho feta moo, boemo bo phahameng ba ho qhibiliha ba molybdenum le tšekamelo ea ho sebetsa ka thata ho matlafatsa botumo ba eona ba ho itšeha ka phephetso.

Ho sebetsa ka katleho mochini oa molybdenum, lisebelisoa tse khethehileng tsa ho itšeha, mekhoa ea ho sebetsana le mekhoa le mekhoa hangata lia hlokahala. Ka mohlala, ho sebelisa lisebelisoa tsa ho itšeha tsa carbide kapa polycrystalline diamond (PCD), hammoho le lebelo le nepahetseng la ho itšeha, ho fepa le mekhoa e pholileng, ho ka thusa ho ntlafatsa machinability ea molybdenum.

Ntle le moo, bakeng sa lits'ebetso tse ling tsa molybdenum, haholo ha o sebetsana le libopeho tse rarahaneng kapa likarolo tse nepahetseng haholo, ho ka khethoa mekhoa e tsoetseng pele ea machining joalo ka machining ea motlakase (EDM) kapa laser cutting.

Ka kakaretso, le hoja boima le boima ba molybdenum bo hlahisa mathata a ho sebetsa ka mochine, ka lisebelisoa le mekhoa e nepahetseng, e ka etsoa ka mochine ka katleho ho hlahisa likarolo tsa boleng bo phahameng bakeng sa mefuta e fapaneng ea liindasteri, sebaka sa sefofane le saense.

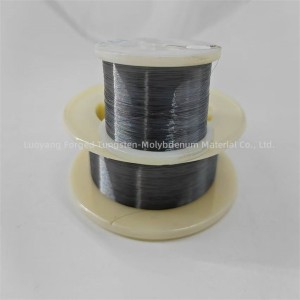

Hangata molybdenum e nkoa e le tšepe ea ductile. E na le tekanyo ea ho senyeha ho lumellang hore e thehoe, e thehoe le ho huloa ka mefuta e sa tšoaneng ea libopeho le likaroloana. Ductility ena ke phello ea bonding ea tšepe ea molybdenum le sebopeho sa kristale, se e lumellang ho senyeha ka polasetiki tlas'a maemo a itseng ntle le ho robeha.

Leha ho le joalo, ke habohlokoa ho hlokomela hore molybdenum ductility e ka angoa ke lintlha tse kang mocheso, litšila le boteng ba likoli. Lithempereichara tse tlase le tlas'a maemo a itseng, molybdenum e ka senyeha haholo, haholo ha e fetoha ka potlako kapa e matla haholo.

Ha e le hantle, molybdenum ductility e etsa hore e tšoanelehe bakeng sa mefuta e fapaneng ea mekhoa ea ho etsa le ea ho etsa, ho kenyelletsa le ho roala, ho etsa le ho taka. Leha ho le joalo, joalo ka litšepe tse ngata, molybdenum ductility e ka angoa ke maemo a ts'ebetso le maemo a tikoloho.

E, molybdenum e ka kobeha, empa ka lebaka la matla a eona a phahameng le boima ba eona, ho hlokahala lisebelisoa tse khethehileng le mekhoa. Mokhoa oa ho koba molybdenum hangata o kenyelletsa ho sebelisa matla a laoloang ho holofatsa tšepe hore e be sebopehong se lakatsehang ntle le ho e senya kapa ho petsoha.

Ho kobeha molybdenum ka katleho, hangata e futhumatsoa ho ea ho mocheso o phahameng ho fokotsa matla a eona le ho eketsa ductility ea eona, ho etsa hore e tepehe le ho ba bonolo ho holofala. Ts'ebetso ena, e bitsoang hot koba, e ka etsa molybdenum ka libopeho tse fapaneng, joalo ka lithupa, maqephe le likarolo tse ikhethileng.

Ho kobeha ho batang ha molybdenum, ho kenyelletsang ho bopa tšepe ka mocheso oa kamore, hoa khoneha hape, empa ho hloka matla a bohlokoa le lisebelisoa tse khethehileng ho fihlela sekoba se lakatsehang ntle le ho baka mapetsong kapa liphoso tse ling.

Litabeng tsa indasteri le tsa tlhahiso, molybdenum e sebelisoa hangata ho etsa likarolo tsa lits'ebetso tse ikhethileng, joalo ka indasteri ea sefofane, lisebelisoa tsa elektroniki le tsa semiconductor. Leha ho le joalo, ka lebaka la tlhaho ea eona e thata, ho koba molybdenum ho lokela ho etsoa ke litsebi tse nang le phihlelo tse sebelisang lisebelisoa tse loketseng le mehato ea tšireletso ho netefatsa botšepehi ba tšepe le boleng ba sehlahisoa se felileng.

Wechat: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com