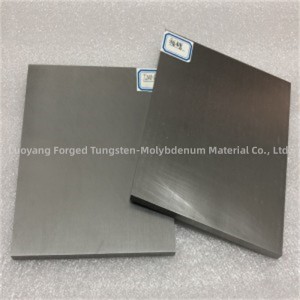

Customized Mo La Alloy Plate Bakeng sa Industrial Furnace Outlet

Tlhahiso ea maqephe a motsoako oa molybdenum-lanthanum (Mo-La) hangata e kenyelletsa letoto la mekhoa ea tlhahiso. Mekhoa ena e ka kenyelletsa: Tokiso ea thepa e tala:

Mohato oa pele o kenyelletsa ho fumana lisebelisoa tse hlokahalang, tse kang molybdenum le lanthanum, ka mokhoa oa phofo kapa lisebelisoa tse ling tse loketseng. Lisebelisoa tsena tse tala li khethoa ho ipapisitsoe le bohloeki ba tsona le sebopeho sa alloy se lakatsehang. Ho Kopanya le Ho Kopanya: Molybdenum le lanthanum powders li kopantsoe hammoho ka tekanyo e nepahetseng ho fumana motsoako o lakatsehang oa motsoako. Motsoako o tsoakane ka botlalo ho etsa bonnete ba ho ajoa ha metsoako. Compaction: Motsoako oa phofo o kopantsoeng o kopanngoa tlas'a khatello e phahameng ho etsa 'mele o motala o teteaneng le o momahaneng. Compaction e ka finyelloa ho sebelisoa mekhoa e kang cold isostatic pressing (CIP) kapa uniaxial pressing. Sintering: 'Mele o motala o tšeloa ka sebōping sa mocheso o phahameng ka tlas'a sepakapaka se laoloang ho finyella maqhama a tiileng-state-diffusion pakeng tsa molybdenum le lanthanum particles. Ts'ebetso ena e etsa hore ho thehoe thepa ea alloy ea Mo-La e teteaneng le e kopantsoeng ka botlalo. Hot rolling: Thepa ea sintered Mo-La alloy e ntan'o kenngoa ts'ebetsong e chesang ho fumana botenya bo hlokahalang le thepa ea mochini. Mokhoa o chesang oa ho roala o kenyelletsa ho fetisa thepa ka letoto la meqolo ka mocheso o phahameng ho fokotsa botenya ba eona le ho ntlafatsa microstructure ea eona. Annealing: Ka mor'a ho chesa, poleiti ea Mo-La alloy e ka 'na ea e-ba le mokhoa oa ho fokotsa khatello ea kelello e ka hare le ho ntlafatsa microstructure ea eona. Annealing hangata e etsoa ka mocheso o itseng le ka nako e laoloang. Phekolo le ho Qetella: Lipoleiti tsa Mo-La alloy li ka fuoa kalafo e eketsehileng ea holim'a metsi joalo ka ho khetha, ho etsa mochini kapa ho bentsa ho fihlela pheletso e hlokahalang le mamello ea boholo. Taolo ea boleng le tlhahlobo: Nakong eohle ea ts'ebetso ea tlhahiso, maqephe a Mo-La alloy a ba le mehato e tiileng ea taolo ea boleng le tlhahlobo ho netefatsa hore thepa ea bona ea mochini, sebopeho sa microstructure le sebopeho sa lik'hemik'hale li fihlela litlhoko tse boletsoeng.

Mekhoa e ka holimo ea tlhahiso ke kakaretso e akaretsang 'me e ka fapana ho itšetlehile ka mekhoa e khethehileng ea tlhahiso le lisebelisoa tse sebelisoang ke bahlahisi ba fapaneng. Mehato e nepahetseng le litekanyetso tse amehang tlhahisong ea maqephe a Mo-La alloy li tla itšetleha ka lintlha tse kang boholo bo hlokahalang ba lakane, thepa ea mochine le tšebeliso ea ho qetela.

Lipampiri tsa alloy tsa Molybdenum-lanthanum (Mo-La) li sebelisoa lits'ebetsong tse fapaneng tsa indasteri ka lebaka la thepa ea tsona e ikhethang. Lipoleiti tsa Mo-La alloy li tsejoa ka matla a tsona a mocheso o phahameng, conductivity e ntle ea mocheso, ho hanyetsa mocheso oa mocheso le machinability e babatsehang. Mehaho ena e etsa lipoleiti tsa Mo-La alloy tse loketseng maemo a mocheso o phahameng le lits'ebetso tse hlokang tse kang:

Likarolo tsa sebōpi: Lipampiri tsa motsoako oa Mo-La li sebelisoa ha ho etsoa libōpi tsa indasteri le lisebelisoa tsa phekolo ea mocheso ka lebaka la bokhoni ba tsona ba ho mamella mocheso o phahameng le ho palama libaesekele. Indasteri ea sepakapaka: Lipoleiti tsa alloy tsa Mo-La li sebelisoa likarolong tsa sepakapaka, ho kenyelletsa le li-rocket nozzles, likamore tse tukang le likarolo tse ling tsa sebopeho sa mocheso o phahameng. Indasteri ea khalase: Lipampiri tsa alloy tsa Mo-La li sebelisoa ts'ebetsong ea tlhahiso ea likhalase, haholo-holo ha ho etsoa hlobo ea khalase, li-stirrers le li-reinforcement tsa tanka ka lebaka la ho hanyetsa ha tsona likhalase tse qhibilihisitsoeng le ho tsosoa ha mocheso. Li-radiator le Heat Exchangers: Lipoleiti tsa alloy tsa Mo-La li sebelisoa lits'ebetsong tsa tsamaiso ea mocheso ho kenyeletsa le litšepe tsa mocheso bakeng sa thepa ea elektronike le lisebelisoa tsa mocheso bakeng sa mekhoa ea mocheso o phahameng. Sepheo sa Sputtering: Letlapa la alloy la Mo-La le sebelisoa e le sepheo sa ho fafatsa bakeng sa ho behoa ha filimi e tšesaane ho semiconductor le tlhahiso ea lisebelisoa tsa elektroniki. Mabitso a Motlakase: Lipoleiti tsa alloy tsa Mo-La li sebelisoa ho likhokahanyo tsa motlakase le li-circuit breakers ka lebaka la conductivity ea tsona e ntle ea motlakase le ho hanyetsa khoholeho ea arc. Lisebelisoa tsa Bongaka le Nyutlelie: Lipampiri tsa motsoako oa Mo-La li sebelisoa ho sireletsa mahlaseli a kotsi le thepa ea mocheso o phahameng indastering ea bongaka le ea nyutlelie.

Ka kakaretso, maqephe a alloy a Mo-La a nkoa e le a bohlokoa ka lebaka la motsoako oa matla a mocheso o phahameng, tsamaiso ea mocheso, le ho hanyetsa maemo a thata, e leng se etsang hore e be tsa bohlokoa haholo makaleng a fapaneng a indasteri.

Wechat: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com