terata ea tungsten le molybdenum Likhoele tsa mouoane

Tungstenmouoane oa mouoane

Bohloeki : W ≥ 99.95%

Maemo a holim'a metsi : Ho hloekisoa ka lik'hemik'hale kapa ho belisoa ka electrolytic.

Sebaka se qhibilihang: 3420 ± 20 ℃

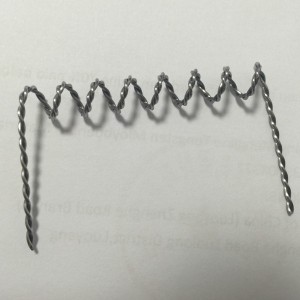

Boholo : ho latela setšoantšo se fanoeng.

Mofuta : E otlolohileng, sebopeho sa U, sebopeho sa V, Basket.Helical.

Kopo: Li-heaters tsa terata tsa Tungsten li sebelisoa haholo bakeng sa ho futhumatsa lintho tse kang tube ea litšoantšo, seipone, polasetiki, tšepe ea tšepe, ABS, PP le lisebelisoa tse ling tsa polasetiki holim'a lintho tse fapaneng tse khabisitsoeng. terata ea Tungsten e sebelisoa haholo-holo e le thepa e tala bakeng sa heater.

molao-motheo oa ts'ebetso: Tungsten e na le sebaka se phahameng sa ho qhibiliha, ho hanyetsa motlakase o phahameng, matla a matle le khatello e tlase ea mouoane, e etsang hore e tšoanelehe ho sebelisoa e le heater. Lera le kenngoa ka har'a heater ka phaposing ea vacuum, 'me le futhumatsoa tlas'a boemo bo phahameng ba vacuum ka hitara (tungsten heater) hore e fetohe mouoane. Ha tsela e sa lefelloeng ea limolek'hule tsa mouoane e le kholo ho feta boholo ba moeli oa kamore ea vacuum, liathomo tsa mouoane Ka mor'a hore limolek'hule li balehe holim'a mohloli oa mouoane, hangata ha li amehe kapa li sitisoa ke limolek'hule tse ling kapa liathomo, e ka fihla ka ho toba holim'a substrate e lokelang ho kenngoa. Ka lebaka la mocheso o tlase oa substrate, filimi e thehoa ka condensation.

Thermal evaporation (resistance evaporation) ke mokhoa oa ho roala o sebelisoang e le karolo ea ts'ebetso ea PVD (Physical Vapor Deposition). Thepa e lokelang ho etsa lera le latelang e futhumatsoa ka kamoreng ea vacuum ho fihlela e fetoha mouoane. Mouoane o entsoeng ke thepa o kokobetsa holim'a substrate ebe o etsa lera le hlokahalang.

Likhoele tsa rona tsa mouoane li tseba ho phahamisa mocheso: Licheso tsena tse thibelang mocheso tse nang le lintlha tse phahameng haholo tsa ho qhibiliha li tla etsa hore tšepe e belise. Ka nako e ts'oanang, khanyetso ea bona e phahameng ea kutu le bohloeki bo ikhethang ba lintho tse bonahalang li thibela tšilafalo leha e le efe ea substrate.