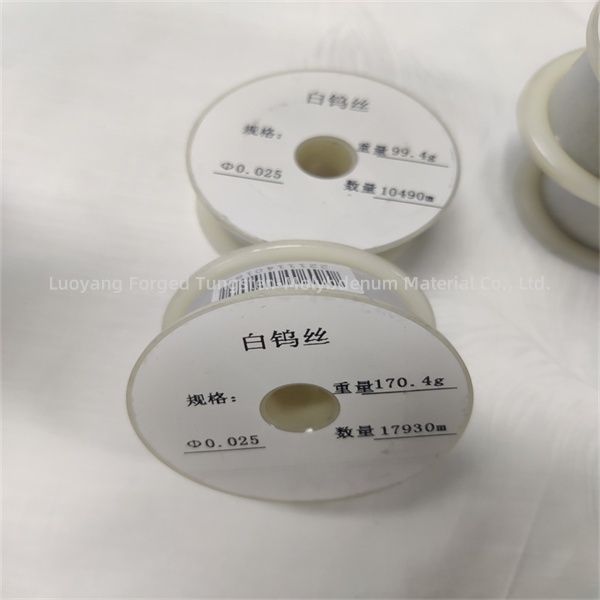

0.025mm tungsten terata 99.95% e hloekileng tungsten filament

Ntle le ho sebelisoa liboneng tsa mabone, terata ea tungsten e sebelisoa haholo e le karolo e ntšang mabone lisebelisoa tse ling tsa elektronike tse kang lithelevishene, li-screens, lasers, vacuum electronic devices, le li-tubes tsa elektronike. Likarolo tse ntšang khanya ea terata ea tungsten lisebelisoa tsena li ka hlahisa khanya e phahameng, botsitso bo botle, le mehloli ea mabone a nako e telele ea bophelo, ho fihlela litlhoko tse fapaneng tsa ts'ebeliso.

| Diameter | Customizable |

| Sebaka sa Tšimoloho | Henan, Luoyang |

| Lebitso la Brand | FGD |

| Kopo | Bongaka, Karolo ea ho futhumatsa, Indasteri |

| Sebopeho | Setereiti |

| Bokaholimo | E bentšitsoe |

| Bohloeki | 99.95% Min |

| Lintho tse bonahalang | E hloekileng W |

| Botenya | 19.3g/cm3 |

| MOQ | 1kg |

| Bophara ba lisebelisoa tsa silikad,m | Boima ba karolo ea silika ea 200mm, mg | Bonyane bolelele, m |

| 5≤d≤10 | 0.075~0.30 | 300 |

| 10≤d≤60 | >0.30 ~ 10.91 | 400 |

| 60<d≤100 | >10.91 ~ 30.30 | 350 |

| 100<d≤150 | >30.30 ~ 68.18 | 200 |

| 150<d≤200 | >68.18~121.20 | 100 |

| 200<d≤350 | >121.20~371.19 | 50 |

| 350<d≤700 | / | E lekana le bolelele ba 75g ka boima |

| 700<d≤1800 | / | E lekana le bolelele ba 75g ka boima |

| Bophara ba silika ld, μm | Boima ba karolo ea silika ea 200mm, mg | Boima ba 200mm ho kheloha karolo ea silika | Phapang ea bophara % | |||

| 0 boemo | Ke lekanya | II boemo | Ke lekanya | II boemo | ||

| 5≤d≤10 | 0.075~0.30 | / | ±4 | ±5 | / | / |

| 10≤d≤18 | ~0.30 ~ 0.98 | / | ±3 | ±4 | / | / |

| 18≤d≤40 | ~0.98 ~ 4.85 | ±2 | ±2.5 | ±3 | / | / |

| 40<d≤80 | ~4.85 ~ 19.39 | ±1.5 | ±2.0 | ±2.5 | / | / |

| 80<d≤300 | — 19.39–272.71 | ±1.0 | ±1.5 | ±2.0 | / | / |

| 300<d≤350 | ~272.71–371.19 | / | ±1.0 | ±1.5 | / | / |

| 350<d≤500 | / | / | / | / | ±1.5 | ±2.0 |

| 500<d≤1800 | / | / | / | / | ±1.0 | ±1.5 |

1. Feme ea rona e Motseng oa Luoyang, Profinseng ea Henan. Luoyang ke sebaka sa tlhahiso bakeng sa merafo ea tungsten le molybdenum, kahoo re na le melemo e feletseng ka boleng le theko;

2. Khampani ea rona e na le basebetsi ba theknoloji ba nang le phihlelo ea lilemo tse fetang 15, 'me re fana ka litharollo le litlhahiso tse lebisitsoeng bakeng sa litlhoko tsa moreki ka mong.

3. Lihlahisoa tsohle tsa rona li hlahlojoa ka thata boleng pele li romeloa linaheng tse ling.

4. Haeba o fumana thepa e nang le bokooa, o ka ikopanya le rona bakeng sa puseletso.

1.Ho ntšoa ha thepa e tala

2.phekolo ea lik'hemik'hale

3. Ho fokotsa phofo ea tungsten

4.Ho hatella le ho siling

5. Ho taka

6. Ho hlakisa

7. Phekolo ea sefahleho

8. Taolo ea Boleng

9. Sephutheloana

1. Lisebelisoa tsa elektronike le lisebelisoa tsa vacuum: Mohala oa Tungsten o sebelisoa e le mochine oa elektronike le lisebelisoa tse futhumatsang bakeng sa lithunya tsa elektronike tse chesang lits'ebetsong tse joalo. Li boetse li sebelisoa hangata lisebelisoa tsa vacuum tse kang li-tubes tse chesang tsa elektronike, li-microscopes tsa elektronike le lisebelisoa tsa ionization ea khase.

2. Tšimo ea mabone: Ka lebaka la bokhoni ba eona ba ho hlahisa leseli le khanyang ka mocheso o phahameng le ho hanyetsa ha eona ho robeha, terata ea tungsten e sebelisoa haholo e le mohloli oa leseli ho li-bulbs tse tloaelehileng tsa incandescent.

3. Resistance heater: Sebaka se phahameng sa ho qhibiliha le ho hanyetsa mocheso o phahameng oa terata ea tungsten ho etsa hore e be thepa e loketseng bakeng sa licheso tsa ho hanyetsa. Hangata li sebelisoa lisebelisoa tsa ho futhumatsa motlakase tsa malapeng le tsa indasteri tse kang litofo tsa motlakase, lionto le li-aene.

4. Welding le ho itšeha: terata ea Tungsten e atisa ho sebelisoa e le lisebelisoa tsa elektrode lits'ebetsong tse phahameng tsa ho cheseletsa le ho itšeha tse kang argon arc welding, laser cutting, le electron beam welding. Sebaka sa eona se phahameng sa ho qhibiliha le ho hanyetsa kutu ho etsa hore e be khetho e nepahetseng bakeng sa ho qalisoa ha arc le ho lokolloa ha hona joale lits'ebetsong tsena.

5. Li-reactors tsa lik'hemik'hale: Ho tse ling tsa lik'hemik'hale tsa lik'hemik'hale, lithapo tsa tungsten li sebelisoa e le li-catalyst le lisebelisoa tse tšehetsang ho ntlafatsa ts'ebetso e sebetsang le botsitso.

Ntle le lits'ebetso tse kaholimo, terata ea tungsten e boetse e sebelisoa haholo indastering ea masela, sebakeng sa sefofane, indastering ea nyutlelie le mafapheng a bongaka.

Bophara ba terata ea tungsten bo hloka ho khethoa ho latela maemo a ts'ebeliso e khethehileng. Ka kakaretso, ha terata ea tungsten e e-na le bophara bo botle haholo, terata ea tungsten e tla fokotseha le ho taboha, empa matla a ho jara le bophelo ba tšebeletso a tla fokotseha ka tsela e tšoanang. Ka hona, hoa hlokahala ho khetha ho latela litlhoko tse khethehileng.

Thepa ea terata ea tungsten e na le tšusumetso e kholo ts'ebetsong ea eona. Tungsten e hloekileng e na le matla a phahameng a mocheso le ho hanyetsa ha kutu ho feta motsoako oa tungsten. Ka hona, maemong ao ho hlokahalang hore ho be le bohloeki bo phahameng le khanyetso e phahameng ea kutu, ho kgothaletswa ho khetha terata e hloekileng ea tungsten; Tungsten alloy e na le matla a betere le ductility, e etsa hore e tšoanelehe bakeng sa lits'ebetso tse khethehileng tse kang spark machining, lisebelisoa tsa elektroniki tsa vacuum le likarolo tse ling.

Nako ea ho qhibiliha ha terata ea tungsten e futhumetseng ka vacuum e itšetlehile ka sekhahla sa mouoane oa tungsten. 'Me ho futhumatsa ha terata ea tungsten moeeng ho hlahisa tungsten oxide. Sebaka se qhibilihang sa tungsten ke likhato tse 3410. Sebaka se qhibilihang sa tungsten oxide, WO3, ke likhato tse 1400-1600. Tlas'a maemo a tloaelehileng a ho sebetsa, mocheso oa filament o pota-potile likhato tse 2500, 'me WO3 e fetoha mouoane ka potlako mocheso ona, e leng se etsang hore filament e qhibilihe ka potlako moeeng.