Likarolo tsa ho futhumatsa Tungsten Sothehileng Filament bakeng sa indasteri ea semiconductor

Ho hlahisa tungsten skeins hangata ho kenyelletsa mehato e mengata:

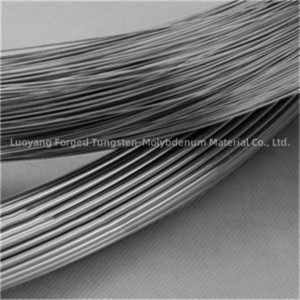

Khetho ea terata ea Tungsten: Sebelisa terata ea tungsten ea boleng bo holimo joalo ka thepa e tala. Mohala o ne o khethiloe ka lebaka la matla a eona a ikhethang, ntlha e phahameng ea ho qhibiliha le ho hanyetsa ho bola, ho etsa hore e loketse ho sebelisoa lits'ebetsong tse phahameng tsa mocheso. Wire annealing: Mohala o khethiloeng oa tungsten o kentsoe ka har'a terata e le hore e ntlafatse matla a eona le ho nolofatsa mokhoa o latelang oa ho sotha. Annealing ke ho futhumatsa terata ho mocheso o phahameng ebe o e pholisa butle, e leng ho thusang ho tlosa khatello ea kelello e ka hare le ho etsa hore terata e be le ductile haholoanyane. Mokhoa oa ho sotha: terata ea tungsten e anneal e ntan'o sotheha ho etsa sebopeho sa filament. Ts'ebetso ea ho sotha e laoloa ka hloko ho netefatsa hore litekanyo tse hlokahalang tsa filament le thepa ea mochine lia finyelloa. Phekolo ea mocheso: Mohala o sothehileng oa tungsten o kenngoa ts'ebetsong ea phekolo ea mocheso ho tsoela pele ho ntlafatsa thepa ea eona ea mechine e kang matla le ductility. Mohato ona o ka kenyelletsa ho futhumatsa filament ho mocheso o itseng ebe o o pholisa tlas'a maemo a laoloang ho fumana sebopeho sa metallographic se lakatsehang. Taolo ea Boleng le Teko: Ho pholletsa le ts'ebetso eohle ea tlhahiso, mehato ea taolo ea boleng e sebelisoa ho netefatsa hore terata ea tungsten e kopana le litlhaloso tse hlokahalang. Sena se kanna sa kenyelletsa ho lekola matla a mochini oa filament, ho nepahala ha dimensional le lisebelisoa tse ling tsa bohlokoa. Ts'ebetso ea ho qetela: Hang ha likhoele tsa tungsten li feta tlhahlobo ea taolo ea boleng, li ka nka mehato e meng ea ts'ebetso, joalo ka kalafo ea bokaholimo kapa kopo ea ho roala, ho ntlafatsa ts'ebetso ea tsona lits'ebetsong tse ikhethileng.

Tlhahiso ea terata e kholehileng ea tungsten e hloka mekhoa e nepahetseng ea tlhahiso le taolo e hlokolosi ea thepa ea thepa ho netefatsa hore terata e hlahisoang e kopana le litlhoko tse phahameng tsa mocheso le thepa ea mochini e hlokahalang lits'ebetsong tse joalo ka tlhahiso ea semiconductor.

Twisted tungsten filament e atisa ho sebelisoa liboneng tsa mabone a incandescent le lisebelisoa tse ling tse fapaneng tsa mabone. Thepa e ikhethang ea Tungsten, ho kenyeletsoa sebaka sa eona se phahameng sa ho qhibiliha le ho tsamaisa mocheso o motle haholo, e e etsa sesebelisoa se loketseng bakeng sa likhoele tse tlamehang ho mamella mocheso o phahameng ha li ntse li boloka botsitso ba sebopeho nakong ea ts'ebetso. Ka lebone la lebone la incandescent, motlakase o fetisoa ka khoele e sothehileng ea tungsten, e etsang hore e chese ebe e ntša leseli le bonahalang. Ho sotha ha filament ho thusa ho eketsa sebaka sa eona sa holimo, ho lumella hore ho be le mocheso o sebetsang hantle le ho ntša khanya. Moqapi ona o boetse o thusa ho eketsa matla le ho tšoarella ha filament, ho o lumella ho mamella khatello ea mocheso le mechine e fumanoang nakong ea ts'ebetso. Tepo ea Tungsten e boetse e sebelisoa linthong tse khethehileng tsa ho futhumatsa, lisebelisoa tsa electron beam, le mefuta e fapaneng ea lisebelisoa tsa mocheso o phahameng moo ho hanyetsanang le kutu le ts'ebetso e tsitsitseng mochesong o phahameng li leng bohlokoa.

Ka kakaretso, ts'ebeliso ea terata ea tungsten e ts'oaretsoeng e phetha karolo ea bohlokoa ho fana ka tharollo e tšepahalang, e sebetsang ea mabone le ho futhumatsa bakeng sa lits'ebetso tse fapaneng tsa indasteri, khoebo le bolulo.

| Lebitso la Sehlahiswa | Filament e Sothehileng ea Tungsten |

| Lintho tse bonahalang | W1 |

| Tlhaloso | Customized |

| Bokaholimo | bentšitsoe |

| Theknoloji | Sintering process, machining |

| Meltng point | 3400 ℃ |

| Botenya | 19.3g/cm3 |

Wechat: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com