99.95% Molybdenum flange E sebelisetsoa ho hokahanya liphaephe

Tlhahiso ea 99.95% ea li-flange tsa molybdenum e kenyelletsa mehato e 'maloa ea bohlokoa ho netefatsa boleng, ho nepahala le ho tšoaneleha ha likhokahanyo tsa liphaephe lits'ebetsong tse fapaneng tsa indasteri. Se latelang ke kakaretso ea mokhoa oa tlhahiso ea 99.95% molybdenum flange:

1. Khetho ea thepa: Mohato oa pele oa ho hlahisa li-flange tsa molybdenum ke ho khetha lisebelisoa tse phahameng tsa molybdenum. Lisebelisoa li lokela ho kopana le maemo a bohloeki a boletsoeng, hangata 99.95%, ho netefatsa thepa e hlokahalang joalo ka ho hanyetsa mocheso o phahameng le ho bola. Lisebelisoa tsa molybdenum li tsoa ho barekisi ba tsebahalang ho netefatsa bohloeki le botsitso ba tsona.

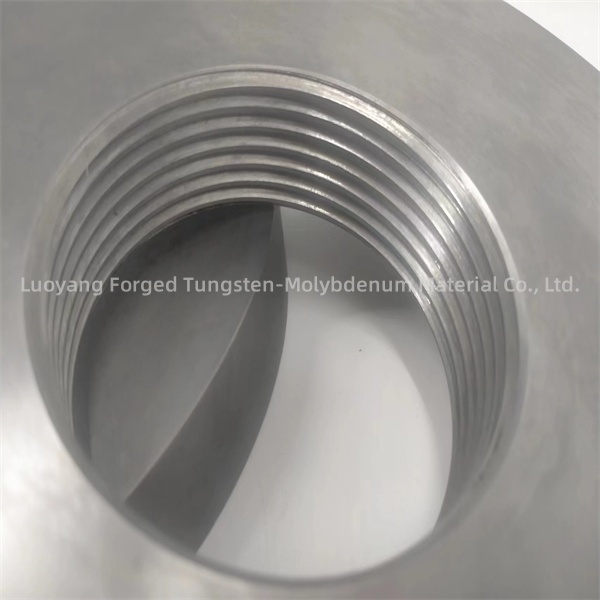

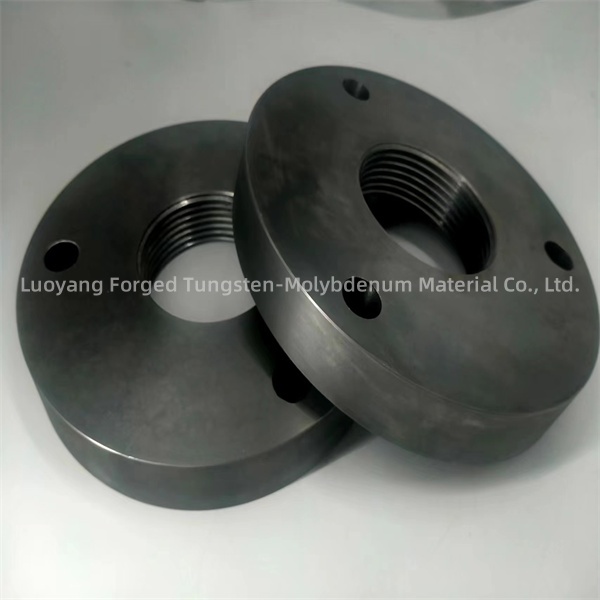

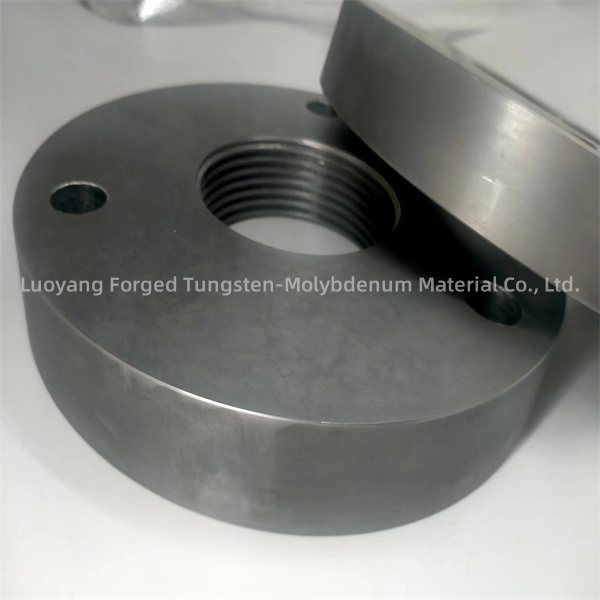

2. Ho theha le ho sebetsa: Theknoloji ea machining e nepahetseng e sebelisetsoa ho sebetsana le thepa ea molybdenum ho etsa flange. Sena se ka kenyelletsa CNC (taolo ea linomoro tsa komporo) ho sila, ho reteleha kapa mekhoa e meng ea machining ho bopa molybdenum hore e be sebopeho se lakatsehang sa flange. Ho sebetsa ka mokhoa o nepahetseng ho bohlokoa ho netefatsa boholo bo nepahetseng le pheletso e kaholimo ea flange.

3. Ho kopanya le ho Welding: Maemong a mang, molybdenum flanges e ka 'na ea hloka ho kopanya kapa ho cheselletsa ho etsa karolo ea ho qetela. Mekhoa e khethehileng ea ho tjheseletsa e loketseng molybdenum, joalo ka welding ea electron beam kapa laser welding, e ka sebelisoa ho netefatsa boits'epo ba sebopeho sa flange le ho boloka litšobotsi tsa eona tse phahameng tsa bohloeki.

4. Phekolo ea sefahleho: Ho itšetlehile ka litlhoko tse khethehileng tsa kopo, li-flange tsa molybdenum li ka phekoloa ka holim'a metsi ho ntlafatsa ts'ebetso ea tsona. Sena se ka kenyelletsa lits'ebetso tse joalo ka ho bentša, ho fetisa kapa ho roala ho ntlafatsa ho hanyetsa ha flange ho kutu le ho senyeha.

5. Taolo ea boleng: Ho pholletsa le ts'ebetso ea tlhahiso, mehato e tiileng ea ho laola boleng e sebelisoa ho netefatsa ho nepahala ha dimensional, boleng ba holim'a metsi le botšepehi ba thepa ea molybdenum flange. Sena se ka kenyelletsa ts'ebeliso ea lisebelisoa tsa tlhahlobo tse tsoetseng pele joalo ka mechini e lekanyang e hokahanyang (CMM) le mekhoa e sa senyeheng ea tlhahlobo ho netefatsa hore flange e kopana le lintlha tse hlokahalang.

6. Tlhahlobo ea ho qetela le ho paka: Ka mor'a hore molybdenum flange e hlahisoe le ho sebetsoa, e tla etsoa tlhahlobo ea ho qetela ho netefatsa hore e finyella litekanyetso tse thata tsa ho hokahanya liphaephe. Sena se kenyelletsa ho netefatsa litekanyo tsa flange, pheletso ea bokaholimo le boleng ka kakaretso. Ka mor'a ho hlahloba ka katleho, flange e tla kenngoa ka hloko ho e sireletsa nakong ea lipalangoang le polokelo.

Ke habohlokoa ho hlokomela hore mekhoa ea tlhahiso ea 99.95% ea molybdenum flange e tlameha ho khomarela melao le litekanyetso tsa indasteri, ho kenyeletsa le tse amanang le bohloeki ba lintho tse bonahalang, bohloeki le ho nepahala ha likarolo. Ho feta moo, lisebelisoa tsa tlhahiso li lokela ho boloka tikoloho e hloekile le e laoloang ho thibela tšoaetso ea flange.

99.95% Molybdenum flanges e na le mefuta e fapaneng ea lisebelisoa, 'me ka lebaka la thepa e ikhethang ea molybdenum, hangata e sebelisoa libakeng tse sa tšoaneng tsa indasteri. Mona ke tse ling tsa lits'ebetso tsa bohlokoa bakeng sa 99.95% molybdenum flanges:

1. Mocheso o phahameng le tikoloho e senyang: Molybdenum flange e sebelisoa liindastering moo mocheso o phahameng le tikoloho e senyang e tloaelehileng. Ka mohlala, ts'ebetsong ea lik'hemik'hale, ho hloekisa le ho hlahisa tšepe, li-flange tsa molybdenum li sebelisoa ho hokahanya liphaephe ho mamella mocheso o feteletseng le ho hanela kutu ho tsoa lik'hemik'hale tse bohale.

2. Lisebelisoa tsa vacuum le li-aerospace: Li-flange tsa Molybdenum ke likarolo tsa bohlokoa tsamaisong ea vacuum, ho kenyeletsa le tse sebelisoang sebakeng sa sefofane, tlhahiso ea semiconductor le lisebelisoa tsa lipatlisiso. Sebaka sa bona se phahameng sa ho qhibiliha le ho hanyetsa ho tsoa ha metsi ho etsa hore ba tšoanelehe ho etsa litiiso tse tšepahalang ka likamoreng tsa vacuum le libaka tse phahameng tsa vacuum.

3. Lisebelisoa tsa Eneji le Nyutlelie: Li-flange tsa Molybdenum li ka sebelisoa lits'ebetsong tse amanang le eneji, ho kenyeletsoa lifeme tsa matla a nyutlelie, li-reactor tsa lipatlisiso le lisebelisoa tse ling moo ho hanyetsa mocheso o phahameng le ho tšepahala ho leng bohlokoa. Li sebelisoa lihokelong tsa liphaephe tse tsamaisang maro a mocheso o phahameng le likhase libakeng tsena tse boima.

4. Ho etsa li-semiconductor le lisebelisoa tsa elektronike: Li-flange tsa Molybdenum ke karolo ea bohlokoa ea mekhoa ea ho etsa semiconductor le lisebelisoa tsa elektronike, haholo-holo libakeng tsa ultra-high vacuum (UHV). Li sebelisetsoa ho aha lits'ebetso tsa vacuum le phepelo ea khase, ho netefatsa likhokahano tse tšepahalang lits'ebetsong tse mahlonoko tse kang ho beha lifilimi tse nyane le tlhahiso ea semiconductor.

5. Mekhoa e phahameng ea khatello: Li-flange tsa Molybdenum li sebelisoa mekhoeng ea khatello e phahameng, e kang ea lik'hemik'hale le liindasteri tsa petrochemical, moo li fanang ka likhokahano tse sireletsehileng le tse tšoarellang bakeng sa liphaephe tse tsamaisang likhase tse phahameng tsa khatello le metsi.

6. Lipatlisiso le Ntšetso-pele: Li-flange tsa Molybdenum li sebelisoa libakeng tsa lipatlisiso le nts'etsopele, ho kenyeletsoa lilaboratori le lisebelisoa tsa tlhahlobo, lisebelisoa tse khethehileng tsa mocheso o phahameng, khatello e phahameng le lisebelisoa tsa vacuum.

Likopong tsena kaofela, thepa e phahameng ea molybdenum, ho kenyelletsa ho hanyetsa mocheso o phahameng, ho hanyetsa kutu le matla a mochine, ho etsa hore 99.95% molybdenum flanges e be karolo ea bohlokoa ho netefatsa botšepehi le ho tšepahala ha likhokahano tsa liphaephe libakeng tse thata tsa indasteri. Ho feta moo, lits'ebetso tse nepahetseng tsa tlhahiso le taolo ea boleng tse amehang ho hlahiseng li-flange tsa molybdenum li netefatsa hore li fihlela litlhoko tse thata tsa ts'ebetso eo li e reretsoeng.

| Lebitso la Sehlahiswa | 99.95% Molybdenum Flange |

| Lintho tse bonahalang | Mo1 |

| Tlhaloso | Customized |

| Bokaholimo | Letlalo le letšo, alkaline e hlatsoitsoe, e bentšitsoe. |

| Theknoloji | Sintering process, machining |

| Meltng point | 2600 ℃ |

| Botenya | 10.2g/cm3 |

Wechat: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com