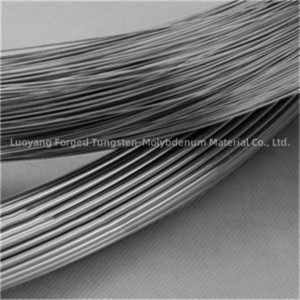

Molybdenum alloy (TZM) Kuboora Mandrel

Nzira yekugadzira yemaperforated mandrels kubva kumolybdenum alloys (yakadai seTZM) inowanzo sanganisira akati wandei akakosha matanho:

Kusarudzwa kwezvinhu: Kutanga sarudza yepamusoro-mhando molybdenum alloy zvinhu, seTZM, inova inoumbwa zvinhu zvemolybdenum, titanium, zirconium uye kabhoni. TZM ine yakanakisa yepamusoro-tembiricha simba, yakanaka yekupisa conductivity, kupfeka kuramba uye deformation kuramba, zvichiita kuti ive chinhu chakanakira punching mandrels. Mechanical kugadzirisa uye kugadzira: Uchishandisa advanced machining tekinoroji uye zvishandiso, iyo molybdenum alloy zvinhu inoumbwa kuita inodiwa chimiro che punching mandrel. Izvi zvinogona kusanganisira kutenderedza, kugaya, kukuya kana mamwe maitiro ekugadzira machini chaiwo kuti uwane zviyero uye kupera kwepasi. Kurapa Kupisa: TZM inogona kuita maitiro ekupisa kupisa kuti ivandudze ma mechanika ayo, kugadzikana kwedimensional uye kuita kwese pakupisa kwakanyanya. Izvi zvinogona kusanganisira kudzorwa kudziyisa uye kutonhora kutenderera kuti uwane izvo zvinodikanwa zvezvinhu. Kurapa Kwepamusoro: Isa mushonga wepamusoro kana kupotera kuti uwedzere kusakara, kuoma kwepamusoro uye kusimba kweiyo mandrel yakaboorwa. Izvi zvinogona kusanganisira maitiro akadai semakemikari vapor deposition (CVD) kana physical vapor deposition (PVD) kuti igadzire chivharo chekudzivirira. Kudzora Hunhu: Yakasimba yemhando yekudzora matanho anoitwa mukati mekugadzira maitiro kuti ave nechokwadi chekuti molybdenum alloy punched mandrels inosangana nekushivirira kwakaringana, kurongeka uye kuita zvinodiwa. Kuongorora Kwekupedzisira uye Kuedzwa: Kunyatsoongorora uye chirongwa chekuyedza chinoitwa kuti chione kutendeka uye kuita kweiyo yakapedzwa kuboora mandrel. Izvi zvinogona kusanganisira kuyerwa kwedimensional, kuongororwa kwepamusoro uye kuyedzwa kwekuita pasi pemashandisirwo emamiriro ekushanda. Kugadzirwa kwe molybdenum alloy piercing mandrels kunoda kutarisisa kusarudzwa kwezvinhu, kunyatsogadzira machining, kupisa kupisa uye kuvimbiswa kwemhando yekuona kuti chishandiso chekupedzisira chinosangana nezvinodiwa zvekuboora simbi uye kugadzira maapplication.

Molybdenum crucibles anoshandiswa zvakanyanya mukupisa kupisa kwepamusoro, kunyanya mumaindasitiri akadai sesimbi, kugadzira magirazi uye sintering yezvinhu. Heano mamwe mashandisirwo chaiwo: Kunyunguduka nekukandira: Zvimedu zvemolybdenum zvinowanzo shandiswa kunyunguditsa nekukanda simbi dzinopisa zvakanyanya uye alloys segoridhe, sirivheri, neplatinamu. Molybdenum's high melting point uye yakanakisa kupisa conductivity inoita kuti ive chinhu chakanakira kumirisana nekupisa kwakanyanya kunosanganisirwa mukunyungudika kwesimbi. Sintering: Molybdenum crucibles anoshandiswa kugadzira ceramic uye simbi poda, uko tembiricha yakakwira inodiwa kuti uwane densification uye kukura kwezviyo. Molybdenum inertness uye kugona kwayo kutsungirira tembiricha yakakwira pasina kuita nechinhu chiri kugadziriswa inoita kuti ive sarudzo yakakodzera yekunyorera kunyorera. Kugadzira magirazi: Molybdenum crucibles anoshandiswa mukugadzirwa kweakakosha magirazi uye girazi ceramics. Molybdenum's high thermal kugadzikana uye inertness inovimbisa kuti haina kusvibisa zvinhu zviri kunyungudutswa, zvichiita kuti ive chinhu chakakosha chekugadzira girazi. Semiconductor kugadzirwa: Muindasitiri ye semiconductor, molybdenum crucibles anoshandiswa mukukura uye kugadzirisa kwekristaro imwechete, sesilicon uye zvimwe semiconductor zvinhu. Kuchena kwepamusoro uye kuramba kumakemikari reactivity kunoita kuti molybdenum ive yakanaka kune aya maapplication. Pakazere, ma molybdenum crucibles anokosheswa nekuda kwekunyanya kupisa kwekushisa, kusagadzikana kwemakemikari, uye kusimba, izvo zvinoita kuti zvive zvakakosha mumhando dzakasiyana dzemaindasitiri nesainzi zvinosanganisira zvinopisa zvakanyanya uye zvinogadzirisa zvinhu.

Wechat:15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com