Molybdenum electrode yakakwirira tembiricha oxidation kuramba, hupenyu hurefu hwebasa

(1) Molybdenum poda ine particle size inotangira pa 2.5um kusvika 4.4um uye okisijeni inotangira kubva 400ppm kusvika 600ppm inomanikidzwa kupinda molybdenum billets. Zvadaro, mabheti e molybdenum anoiswa muvira rekudzivirira sintering uye pre sintered pasi pevacuum kana hydrogen gasi semhepo inodzivirira. Iyo pre sintering process inosanganisira kutanga kusimudza tembiricha kubva mukamuri tembiricha kwemaawa 4-6 kusvika 1200 ℃, kuibata kwemaawa maviri, uyezve kusimudza tembiricha kubva pa1200 ℃ kwemaawa 1-2 kusvika 1350 ℃, uchiibata kwe2-4. maawa;

(2) Isa pre sintered molybdenum billet munhanho (1) muchoto chepakati frequency induction furace uye sinter iyo pasi pehydrogen gasi semhepo inodzivirira kuti uwane molybdenum electrodes nekuchena kwemhando inopfuura 99.99%. Iyo sintering maitiro ndeaya anotevera: kutanga, kupisa uye sinter kubva mukamuri tembiricha kwemaawa 1-2 kusvika 1500 ℃, chengeta ichidziya kwemaawa 1-2, wozopisa uye sinter kubva 1500 ℃ kwemaawa 1-2 kusvika 1750 ℃. , ichengetedze ichidziya kwemaawa 2-4, uye wozopisa uye sinter kubva ku1750 ℃ kwemaawa 1-2 kusvika 1800 ℃ kusvika 1950 ℃, Ramba uchidziya kwemaawa 4-6.

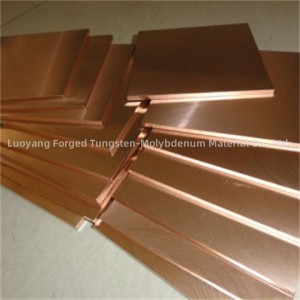

Molybdenum electrode ndeye molybdenum electrode zvinhu inoshandisa zvayakanakira zvayakasiyana, tembiricha kuramba, inoenderera mberi, yakanaka conductivity, yakagadzikana mipendero, uye yakanakisa corrosion kuramba kuvandudza hunhu hwayo hwese uye hupenyu hwesevhisi. Iyo molybdenum electrode ine sirivheri grey simbi inopenya. Iyi ndiyo yakasiyana-siyana yefoged yepakati frequency furefurnace mushure me isostatic kudzvanya sintering, iyo inozotenderedzwa, yakakungurutswa, yakarongwa, uye pasi.

Kushandiswa kwe molybdenum electrodes mumoto wegirazi ndechimwe chezvikonzero zvinokanganisa hupenyu hwavo hwebasa, izvo zvinogona kuverengerwa kune zvinotevera zvinhu. Chekutanga, nzira yekuisa maelectrodes, akadai seyepamusoro yakaiswa electrode isina zvidhinha zve electrode, inogona kuvandudza hupenyu hwebasa rechoto, asi zviri nyore kugadzira kumusoro kunopisa, uye maelectrodes anowanzo kuputsika, izvo zvinoda zvakanyanya zvinodiwa. nokuda kwechimiro chepamusoro pezvinhu. Iyo yepasi yakaiswa electrode ine kushomeka kwekuora, asi inoda yakakwirira dhizaini uye zvinodiwa zvemidziyo. Kukukurwa kwezvidhinha zvemagetsi emagetsi zvakati wandei. Kana matanho ekudzivirira akakosha asina kutorwa, anozowedzera kukukurwa kwechoto uye ane zvinodiwa zvakanyanya zvekushanda nekushandiswa.

Yechipiri ndeye kushandisa molybdenum electrode bhachi remvura nemazvo. Iyo electrode yemvura bhachi ine pazasi yakaiswa maelectrodes inonetsa kutsiva, saka yakakomba mvura inodonha inowanzoitika, zvichiita kuti choto chivhare. Nokudaro, zvinodikanwa kugara uchiongorora uye kuchengetedza jekete remvura uye mvura yakapfava. Pamusoro pezvo, kusvibiswa uye kuwanda kwe molybdenum electrodes zvakare kune imwe mhedzisiro pamhando yehuni negirazi. Chiyero chetsvina mumolybdenum electrodes uye kuwanda uye kufanana kwemolybdenum electrodes zviratidzo zvakakosha pakuyera molybdenum electrodes. Molybdenum electrodes ine tsvina shoma inogona kugadzira girazi nekujeka kuri nani. Mukuwedzera, kusvibiswa kwakanyanya kwesimbi uye nickel mu electrode kunogonawo kukanganisa hupenyu hwe electrode. Iyo electrode density yakakwira uye yunifomu, iyo isingagone kungovandudza hupenyu hwesevhisi ye electrode, kudzivirira kukukurwa kwe electrode, uye kukonzera huwandu hukuru hwemolybdenum particles kusanganiswa mugirazi, asiwo zvinobudirira kuvandudza kushanda kwegirazi.

Muchidimbu, molybdenum electrodes inonyanya kushandiswa mukugadzira magirazi uye isingawanzo maindasitiri epasi.

| Product Name | Molybdenum electrode |

| Material | Mo1 |

| Tsanangudzo | Customized |

| Surface | Ganda dema, alkali yakashambidzwa, yakakwenenzverwa. |

| Technique | Sintering process, machining |

| Meltng point | 2600 ℃ |

| Density | 10.2g/cm3 |

Wechat:15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com