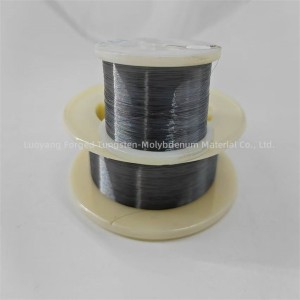

molybdenum denderedzwa molybdenum raundi molybdenum machined chikamu

Ehe, molybdenum inoonekwa sechinhu chakaoma kucheka nekuda kwekuoma kwayo uye kuoma kwayo. Kuoma kwayo uye kuramba deformation kunoita kuti zviome kuchina uchishandisa zvechinyakare zvekucheka maturusi uye matekiniki. Pamusoro pezvo, molybdenum yakakwira kunyungudika uye tsika yekushanda yakaoma inowedzera kuwedzera mukurumbira wayo sechinhu chinonetsa chekucheka.

Kuti ubudirire muchina molybdenum, maturusi ekucheka akasarudzika, maparamita ekugadzirisa uye matekiniki anowanzo kudiwa. Semuenzaniso, kushandisa carbide kana polycrystalline diamond (PCD) kucheka maturusi, pamwe chete neakakodzera kucheka kumhanya, chikafu uye inotonhorera nzira, zvinogona kubatsira kuvandudza machinability ye molybdenum.

Pamusoro pezvo, kune mamwe mashandisirwo emolybdenum, kunyanya kana uchigadzira maumbirwo akaomarara kana akanyanya-chaiyo zvikamu, epamberi machining maitiro akadai semagetsi discharge machining (EDM) kana laser yekucheka inogona kufarirwa.

Pakazere, nepo kuoma kwe molybdenum uye kuomarara kunounza matambudziko ekugadzira machining, aine maturusi akakodzera uye matekiniki, inogona kugadzirwa zvinobudirira kugadzira zvikamu zvemhando yepamusoro zveakasiyana maindasitiri, aerospace, uye mashandisirwo esainzi.

Molybdenum inowanzoonekwa se ductile simbi. Iine dhigirii rekusagadzikana kunobvumira kuti iumbwe, iumbwe uye inokweverwa mumhando dzakasiyana dzemaumbirwo uye zvikamu. Iyi ductility ndiyo mhedzisiro yemolybdenum's metallic bonding uye crystal chimiro, iyo inobvumira kuti iparadze mupurasitiki pasi pemamwe mamiriro pasina kutyora.

Zvisinei, zvakakosha kuziva kuti molybdenum's ductility inogona kukanganiswa nezvinhu zvakadai sekushisa, kusvibiswa uye kuvapo kwekuremara. Pakudziya kwakadzika uye pasi pemamwe mamiriro, molybdenum inogona kuita brittle, kunyanya kana ichikurumidza kana kushanduka zvakanyanya.

Muchokwadi, molybdenum's ductility inoita kuti ive yakakodzera kune akasiyana ekugadzira uye kugadzira maitiro, anosanganisira rolling, forging uye kudhirowa. Nekudaro, senge simbi zhinji, molybdenum's ductility inogona kukanganiswa nekugadzirisa mamiriro uye zvakatipoteredza.

Hongu, molybdenum inogona kukotama, asi nekuda kwesimba rayo rakakura uye kuoma, hunyanzvi hwekushandisa uye matekiniki anodiwa. Maitiro ekupeta molybdenum anowanzo sanganisira kushandisa simba rinodzorwa kutsveyamisa simbi kuita chimiro chaunoda pasina kuita kuti ipwanye kana kutsemuka.

Kuti unyatso kubhenda molybdenum, inowanzopisa kusvika kune tembiricha yakakwira kuderedza simba rayo uye kuwedzera ductility yayo, ichiita kuti iwedzere kuchinjika uye nyore kuremara. Kuita uku, kunonzi kubhenda kunopisa, kunogona kuumba molybdenum kuita maumbirwo akasiyana-siyana, akadai setsvimbo, mashizha uye zvikamu zvetsika.

Kukotama kutonhora kwe molybdenum, kunosanganisira kuumba simbi patembiricha yekamuri, zvakare kunogoneka, asi kunoda simba rakakura uye maturusi ane hunyanzvi kuti awane kubhenda kwaunoda pasina kukonzera kutsemuka kana kumwe kukanganisa.

Mumaindasitiri nekugadzira zvigadziriso, molybdenum inowanzoshandiswa kugadzira zvikamu zvehunyanzvi maapplication, senge aerospace, zvemagetsi, uye semiconductor maindasitiri. Nekudaro, nekuda kwehunhu hwayo hwakaoma, kubhenda molybdenum kunofanirwa kuitwa nenyanzvi dzine ruzivo vachishandisa michina yakakodzera uye matanho ekuchengetedza kuve nechokwadi chekuvimbika kwesimbi uye kunaka kwechigadzirwa chakapedzwa.

Wechat:15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com