melting lauj kaub tungsten crucible rau kub kub rauv

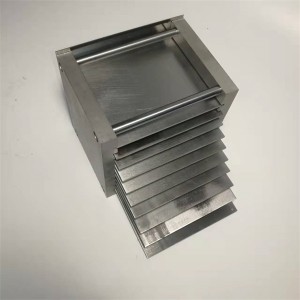

Tungsten crucible yog ib hom hlau tungsten khoom, feem ntau muab faib ua ob hom: sintering thiab stamping. Cov txheej txheem npaj ntawm tungsten crucible suav nrog hom spining, thiab lwm yam tensity, tsis muaj zog, thaum muaj nqi qis, thiab cov khoom lag luam tseem tsawg .

Daim ntawv thov dav ntawm tungsten crucibles tau txais txiaj ntsig los ntawm lawv cov khoom zoo heev ntawm lub cev thiab tshuaj lom neeg, nrog rau cov ntsiab lus melting siab, siab zog, zoo corrosion kuj, thiab hnav tsis kam. cov

| Qhov ntev | Raws li koj xav tau |

| Qhov Chaw Keeb Kwm | Luoyang, Henan |

| Hom Lub Npe | FGD |

| Daim ntawv thov | Kev lag luam |

| Nto | Polished |

| Purity | 99.95% Min |

| Khoom siv | Ntshiab tungsten |

| Qhov ntom | 19.3g / cm3 |

| melting point | 3400 ℃ |

| Kev siv ib puag ncig | Nqus ib puag ncig |

| Kev siv kub | 1600-2500 ℃ |

| Cov khoom tseem ceeb | W ≥ 99.95% |

| Cov ntsiab lus impurity ≤ | |

| Pb | 0.0005 |

| Fe | 0.0020 Nws |

| S | 0.0050 Nws |

| P | 0.0005 |

| C | 0.01 ib |

| Cr | 0.0010 Nws |

| Al | 0.0015 Nws |

| Cu | 0.0015 Nws |

| K | 0.008 0 |

| N | 0.003 ib |

| Sn | 0.0015 Nws |

| Si | 0.0020 Nws |

| Ca | 0.0015 Nws |

| Na | 0.0020 Nws |

| O | 0.008 ib |

| Ti | 0.0010 Nws |

| Mg | 0.0010 Nws |

| Khoom siv | 100% recrystallization kub ℃ | (Lub sij hawm Annealing: 1 teev) |

|

| Deformation degree = 90% | Deformation degree = 99.99% |

| Ntshiab W | 1350 | - |

| WM | - | 2000 |

| WL 10 | 1500 | 2500 |

| WL 15 | 1550 | 2600 |

| wb 05 | 1700 | - |

| WR26 | 1750 | - |

1. Peb lub Hoobkas nyob hauv Luoyang City, Henan Province. Luoyang yog thaj chaw tsim khoom rau tungsten thiab molybdenum mines, yog li peb muaj qhov zoo ntawm qhov zoo thiab tus nqi;

2. Peb lub tuam txhab muaj cov kws tshaj lij nrog ntau tshaj 15 xyoo kev paub, thiab peb muab cov kev daws teeb meem thiab cov lus qhia rau txhua tus neeg siv khoom xav tau.

3. Tag nrho peb cov khoom raug soj ntsuam nruj ua ntej xa tawm.

4. Yog tias koj tau txais cov khoom tsis raug, koj tuaj yeem tiv tauj peb kom them rov qab.

1. Npaj tungsten hmoov

(Ua ntej, npaj tungsten hmoov thiab tshuaj ntsuam nws kom nyias nyias thiab nplua tungsten hmoov)

2. Ua ke batch

(Batch ua ntawm tungsten hmoov nrog tib cov tshuaj muaj pes tsawg leeg tab sis los ntawm cov txheej txheem ntau lawm)

3. isostatic nias

(Muab cov hmoov tungsten ua ke rau hauv lub thawv ntim ntim nrog cov kua, thiab maj mam nias nws los ntawm lub zog siab kom txo tau qhov kev ncua deb ntawm cov molecules, nce ceev, thiab txhim kho lub cev ntawm cov khoom tsis hloov nws cov tsos)

4. Rough billet machining

(Tom qab ua tiav cov isostatic nias, cov txheej txheem ntxhib yog nqa tawm)

5. Intermediate zaus sintering

(Tso cov txheej txheem ntxhib rau hauv qhov nruab nrab zaus sintering rauv rau kev ua haujlwm sintering)

6. Kev ua haujlwm zoo ntawm lub tsheb

(Tig cov khoom sintered kom tau qhov ntev thiab cov duab meej)

7. Tshawb xyuas lub ntim

(Saib cov txheej txheem tungsten crucible thiab ntim nws tom qab dhau qhov kev tshuaj xyuas)

Quartz iav melting: Tungsten crucibles kuj tau siv dav hauv quartz iav melting furnaces. Raws li ib qho ntawm cov khoom siv tseem ceeb rau melting quartz iav, lawv lub zog kub thiab corrosion kuj ua rau quartz iav kom yaj thiab tsim cov duab xav tau hauv qhov kub thiab txias.

Lub deformation ntawm lub crucible yog tshwm sim los ntawm uneven expansion ntawm txawv qhov chaw ntawm lub crucible vim yog overheating thiab tsis sib xws. Kev kub ceev thiab tsis sib xws ntawm lub crucible yuav tsum zam.

Pom zoo qhov kub thiab txias yog 1600-2500 degrees Celsius.