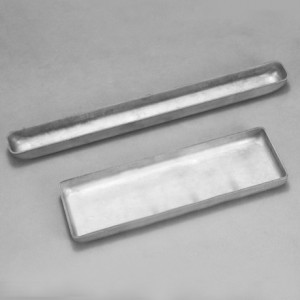

Tantalum screws thiab ceev tantalum fasteners

Cov txheej txheem tsim khoom ntawm tantalum bolts thiab txiv ntseej nruj me ntsis ua raws li cov qauv zoo los xyuas kom meej cov kav ntev thiab kev ntseeg siab ntawm cov khoom. Lawv tuaj yeem tiv taus qhov kub thiab txias heev, thiab tswj kev ua haujlwm ruaj khov txawm tias nyob hauv qhov chaw huab cua. Yog li ntawd, tantalum bolts thiab txiv ntseej yog feem ntau siv rau hauv kev xav tau kev lag luam thiab kev tshawb fawb, xws li aerospace, nuclear chaw, thiab kev tsim cov khoom siv kho mob siab. cov

| Qhov ntev | Raws li koj xav tau |

| Qhov Chaw Keeb Kwm | Luoyang, Henan |

| Hom Lub Npe | FGD |

| Daim ntawv thov | Kev lag luam, semiconductor |

| Purity | 99.95% |

| Melting point | 2996 ℃ |

| Qhov ntom | 16.65g / cm3 |

| Hardness | HV 250 |

| λ/nm | f | W | F | S* | CL | G |

| 271.5 ib | 0.055 ib | 0.2 | NA | 30 | 1.0 | |

| 260.9 (D) | 0.2 | NA | 23 | 2.1 | ||

| 265.7 ib | 0.2 | NA | 2.5 | |||

| 293.4 ib | 0.2 | NA | 2.5 | |||

| 255.9 ib | 0.2 | NA | 2.5 | |||

| 264.8 ib | 0.2 | NA | x | |||

| 265.3 ib | 0.2 | NA | 2.7 | |||

| 269.8 ib | 0.2 | NA | 2.7 | |||

| 275.8 ib | 0.2 | NA | 3.1 | |||

| 277.6 ib | 0.2 | NA | 58 |

1. Peb lub Hoobkas nyob hauv Luoyang City, Henan Province. Luoyang yog thaj chaw tsim khoom rau tungsten thiab molybdenum mines, yog li peb muaj qhov zoo ntawm qhov zoo thiab tus nqi;

2. Peb lub tuam txhab muaj cov kws tshaj lij nrog ntau tshaj 15 xyoo kev paub, thiab peb muab cov kev daws teeb meem thiab cov lus qhia rau txhua tus neeg siv khoom xav tau.

3. Tag nrho peb cov khoom raug soj ntsuam nruj ua ntej xa tawm.

4. Yog tias koj tau txais cov khoom tsis raug, koj tuaj yeem tiv tauj peb kom them rov qab.

1. raw khoom npaj

(Xaiv cov ntaub ntawv tsim nyog ntawm cov xaim lossis lub rooj tsavxwm kom ntseeg tau tias cov khoom ua tau raws li tus qauv xav tau.)

2. Hlau ua / stamping

(Hloov yog ua tiav rau hauv cov ntsia hlau blanks los ntawm cov tshuab taub hau txias; Cov ntawv hlau yog xuas nrig ntaus rau hauv cov txiv ntoo blanks siv lub punch xovxwm. Cov kauj ruam no yog tsim cov qauv ntawm cov ntsia liaj qhov rooj thiab cov txiv ntoo).

3. Kev kho cua sov

(Tshav kub kho qhov khoob, xws li quenching, tempering, thiab lwm yam, txhawm rau txhim kho hardness thiab toughness, kom ntseeg tau tias cov khoom siv ntawm lub fastener)

4. Rolling xov/tapping hniav

(Screw blanks yog threaded siv lub tshuab dov; Cov txiv ntoo dawb yog ua tiav nrog cov xov sab hauv ntawm lub tshuab tapping)

5. Kev kho deg

(Kev kho deg xws li electroplating, oxidation, phosphating, thiab lwm yam. yog ua raws li qhov yuav tsum tau ua kom muaj kev tiv thaiv corrosion thiab zoo nkauj.

6. kev kuaj pom

(Siv gauges, optical instruments, thiab lwm yam. los xyuas kom meej cov khoom tiav rau qhov ntev, xov raug, defects, thiab lwm yam., los xyuas kom meej zoo)

7. Kev tshuaj xyuas thiab ntim khoom

(Tshem tawm cov khoom tsis sib haum los ntawm lub tshuab vibrating npo, faib lawv raws li cov lus qhia tshwj xeeb, thiab tom qab ntawd automate lossis manually ntim lawv)

8. kev tswj kom zoo

(Sampling rau kev ntsuam xyuas kev ua tau zoo, xws li kev ntsuas tensile, kuaj torque, thiab lwm yam, kom ntseeg tau tias cov khoom ua tau raws li kev lag luam thiab cov neeg siv khoom qauv)

Molybdenum lub hom phiaj feem ntau yog siv hauv X-ray raj rau kev kuaj mob, tshuaj xyuas kev lag luam, thiab kev tshawb fawb tshawb fawb. Cov ntawv thov rau cov hom phiaj molybdenum yog feem ntau hauv kev tsim hluav taws xob X-rays rau kev kuaj pom, xws li suav tomography (CT) scans thiab radiography.

Molybdenum lub hom phiaj yog nyiam rau lawv qhov siab melting point, uas tso cai rau lawv tiv taus qhov kub thiab txias tsim thaum lub sij hawm X-ray ntau lawm. Lawv kuj muaj thermal conductivity zoo, pab kom dissipate tshav kub thiab ntev lub neej ntawm X-ray raj.

Ntxiv nrog rau kev kuaj pom kev kho mob, cov hom phiaj molybdenum yog siv rau kev sim tsis muaj kev puas tsuaj hauv kev lag luam, xws li tshuaj xyuas cov vuam, cov kav dej thiab cov khoom siv hauv aerospace. Lawv kuj tau siv rau hauv cov chaw tshawb fawb uas siv X-ray fluorescence (XRF) spectroscopy rau kev txheeb xyuas cov khoom siv thiab kev txheeb xyuas lub ntsiab lus.

Kev sib txuam ntawm cov ntsia hlau thiab cov txiv ntseej yuav tsum xyuas kom meej tias cov xov ntawm cov ntsia hlau thiab cov txiv ntseej sib haum. Ntawm no yog cov kauj ruam dav dav rau kev sib txuam screws thiab ceev:

1. Txiav txim siab qhov loj me: ntsuas lub cheeb thiab qhov ntev ntawm cov ntsia hlau los txiav txim nws qhov loj. Qhov ntau thiab tsawg ntawm cov ntsia hlau raug xaiv siv tus lej ua raws li ib feem, xws li # 8-32 lossis # 10-24.

2. Txheeb xyuas hom xov: Cov ntsia hlau thiab cov txiv ntoo tuaj yeem muaj ntau hom xov, xws li cov xov ntxhib lossis cov xov zoo. Nws yog ib qho tseem ceeb uas cov xov hom ntawm cov ntsia hlau sib tw rau cov txiv ntoo sib xws.

3. Txheeb xyuas cov xov suab: Cov xov suab hais txog qhov kev ncua deb ntawm cov xov uas nyob ib sab ntawm cov ntsia hlau lossis txiv ntoo. Xyuas kom tseeb tias cov ntsia hlau thiab cov txiv ntseej muaj tib lub xov suab kom paub tseeb tias lawv sib raug zoo.

4. Xav txog cov ntaub ntawv thiab lub zog: Xaiv cov ntsia hlau thiab cov txiv ntoo ua los ntawm cov khoom siv sib xws thiab muaj cov kev ntsuas lub zog zoo sib xws kom ntseeg tau tias lawv tuaj yeem tiv taus cov ntawv thov.

5. Kuaj qhov haum: Ua ntej xaiv zaum kawg, sim cov ntsia hlau thiab cov txiv ntseej kom paub tseeb tias lawv haum ua ke zoo thiab ruaj ntseg.

Los ntawm ua raws li cov kauj ruam hauv qab no, koj tuaj yeem ua tau zoo phim cov ntsia hlau thiab cov txiv ntoo rau koj daim ntawv thov tshwj xeeb.

Thaum xav txog kev tsim xov rau tantalum bolts thiab ceev, muaj ntau yam teeb meem tseem ceeb uas yuav tsum tau muab sau tseg vim tantalum cov khoom tshwj xeeb:

1. Material Compatibility: Tantalum yog cov hlau uas tsis muaj corrosion, yog li nws yog ib qho tseem ceeb kom ntseeg tau tias cov ntaub ntawv siv rau cov txiv ntseej thiab bolts kuj sib xws nrog tantalum. Kev siv cov ntaub ntawv uas tsis sib haum nrog tantalum tuaj yeem ua rau galvanic corrosion thiab cuam tshuam qhov kev ncaj ncees ntawm kev sib koom tes.

2. Thread lubrication: Tantalum muaj ib tug nyiam hnav, uas yog cov txheej txheem ntawm cov khoom adhesion thiab hloov ntawm zawv zawg qhov chaw. Yuav kom txo tau qhov teeb meem no, cov xov zoo lubrication yuav tsum tau txiav txim siab thaum tsim tantalum bolts thiab txiv ntseej los tiv thaiv kev hnav thiab xyuas kom zoo sib dhos thiab disassembly.

3. Xov lub zog: Tantalum yog cov hlau mos, yog li lub zog ntawm cov khoom yuav tsum tau muab coj los txiav txim siab thaum tsim cov xov. Nws yog ib qho tseem ceeb los xyuas kom meej tias daim ntawv xov thiab kev koom tes muab lub zog txaus rau daim ntawv thov npaj thaum tsis txhob muaj kev ntxhov siab ntau dhau.

4. Daim ntawv xov: xov daim ntawv, txawm tias metric, uniform, los yog lwm yam qauv, yuav tsum tau ua tib zoo xaiv los xyuas kom meej compatibility nrog mating qhov chaw thiab kom tau raws li cov kev cai ntawm daim ntawv thov.

5. Nto Finish: Tantalum bolts thiab txiv ntseej yuav tsum muaj qhov du thiab zoo ib yam ua tiav kom txo tau qhov hnav thiab xyuas kom muaj kev sib khi kom zoo thaum sib koom ua ke raug cov kua lossis roj.

Los ntawm kev hais txog cov teeb meem no hauv tantalum bolt thiab txiv ntseej xov tsim, koj tuaj yeem ua kom ntseeg tau thiab ua haujlwm ntawm koj lub tshuab fastening hauv tantalum daim ntaub ntawv.