Molybdenum zoo li tus machined qhov chaw Muaj muaj

Kev tsim cov molybdenum tsim machined feem feem ntau muaj ob peb kauj ruam tseem ceeb: kev xaiv cov khoom: Molybdenum yog siv los ua raw khoom nyob rau hauv daim ntawv ntawm molybdenum ore, uas yog ces ua rau extract molybdenum oxide. Cov oxide yog ua tiav los tsim molybdenum hlau hmoov, uas yog siv los ua cov khoom siv raw rau molding thiab ua cov txheej txheem. Shaping: Molybdenum hlau hmoov feem ntau zoo li siv cov hmoov metallurgy txheej txheem xws li nias thiab sintering. Nyob rau hauv cov txheej txheem no, molybdenum hmoov yog compacted nyob rau hauv kev kub siab los tsim ib lub cev ntsuab, uas yog ces sintered nyob rau hauv high kub kom ua tau raws li qhov yuav tsum tau ceev thiab lub zog. Machining: Thaum cov khoom siv molybdenum tau tsim rau hauv cov duab uas xav tau, nws dhau los ua cov txheej txheem machining xws li tig, milling, drilling thiab sib tsoo kom ua tiav qhov kawg qhov ntev thiab qhov chaw tiav uas xav tau rau qhov tshwj xeeb. Kev Tswjhwm Zoo: Thoob plaws hauv tag nrho cov txheej txheem tsim khoom, kev tswj xyuas kev ua tau zoo yog siv los xyuas kom meej tias molybdenum qhov chaw ua tau raws li cov lus qhia tshwj xeeb rau qhov raug qhov tseeb, cov khoom siv kho tshuab thiab qhov chaw zoo. Qhov no yuav suav nrog kev sim tsis muaj kev puas tsuaj, kev tshuaj xyuas qhov ntev thiab kev tshuaj xyuas cov khoom siv. Tiav: Tom qab machining, molybdenum qhov chaw yuav tau txais kev kho deg ntxiv los yog txheej txheej los txhim kho lawv cov kev ua tau zoo lossis kev tiv thaiv corrosion, nyob ntawm seb daim ntawv thov. Zuag qhia tag nrho, kev tsim cov molybdenum tsim machined qhov yuav tsum tau precision manufacturing cov tswv yim thiab nruj ua raws li cov khoom specifications kom paub meej tias cov khoom kawg ua tau raws li qhov xav tau ntawm cov ntawv thov kev lag luam..

Vim tias molybdenum muaj cov khoom tshwj xeeb xws li cov ntsiab lus siab melting, zoo heev kub-kub lub zog, thiab zoo hluav taws xob thiab thermal conductivity, molybdenum tshwj xeeb-zoo li tus machined qhov chaw yog dav siv nyob rau hauv ntau yam lag luam. Qee qhov kev siv rau molybdenum tsim machined qhov chaw muaj xws li: Aerospace thiab Defense: Molybdenum qhov chaw yog siv nyob rau hauv aerospace thiab tiv thaiv daim ntaub ntawv vim lawv muaj peev xwm tiv taus kub thiab mechanical kev nyuaj siab. Lawv tuaj yeem pom nyob rau hauv cov khoom siv dav hlau, cov foob pob hluav taws thiab lwm yam khoom siv tiv thaiv. Electronics thiab Semiconductor Manufacturing: Molybdenum yog siv rau hauv kev tsim cov khoom siv hluav taws xob semiconductor, nrog rau kev sib cuag hluav taws xob, cov dab dej kub thiab lwm yam khoom siv hluav taws xob uas yuav tsum tau muaj qhov kub thiab txias thiab thermal conductivity. Cov Cheebtsam Kub Kub Kub: Cov khoom siv molybdenum yog siv rau hauv kev tsim cov cua kub kub, xws li cov iav, ceramics thiab steel ntau lawm, qhov chaw uas lawv muaj cov cua kub zoo heev thiab txhua yam muaj zog. Cov Khoom Siv Kho Mob: Molybdenum Cheebtsam yog siv rau hauv cov khoom siv kho mob thiab cov khoom siv vim lawv cov biocompatibility thiab corrosion kuj, ua rau lawv tsim nyog rau kev siv xws li cog thiab phais. Iav Manufacturing: Molybdenum Cheebtsam yog siv nyob rau hauv lub iav ntau lawm txheej txheem rau electrodes, txau, thiab lwm yam Cheebtsam uas yuav tsum tau tiv taus qhov kub thiab corrosive ib puag ncig ntawm iav manufacturing lag luam. Kev siv teeb pom kev zoo thiab kev siv cua sov: Molybdenum yog siv rau ntau yam kev siv teeb pom kev zoo, nrog rau cov khoom siv teeb pom kev zoo thiab cov khoom siv hluav taws xob, nrog rau cov dab dej kub thiab lwm yam khoom siv uas tsim los tswj kom zoo thiab ua kom sov. Zuag qhia tag nrho, molybdenum tsim machined qhov tseem ceeb nyob rau hauv kev lag luam uas yuav tsum tau cov ntaub ntawv los tiv thaiv huab cua kub, corrosive ib puag ncig, thiab siab mechanical kev nyuaj siab thaum tuav lawv cov qauv kev ncaj ncees thiab functionality.

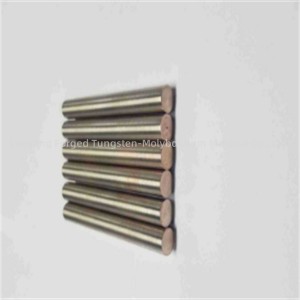

| Khoom npe | Molybdenum zoo li tus machined qhov chaw Muaj muaj |

| Khoom siv | Mo1 |

| Specification | Customized |

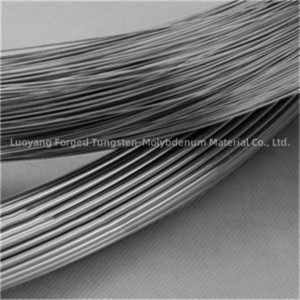

| Nto | Cov tawv nqaij dub, alkali ntxuav, polished. |

| Cov txheej txheem | Sintering txheej txheem, machining |

| Meltng point | 2600 ℃ |

| Qhov ntom | 10.2g / cm3 |

Wechat: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com