Izingxenye Zokushisa I-Tungsten Twisted Filament yemboni ye-semiconductor

Ukukhiqizwa kwama-tungsten skein ngokuvamile kuhilela izinyathelo ezimbalwa:

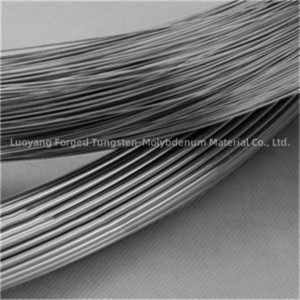

Ukukhetha intambo ye-Tungsten: Sebenzisa i-high-purity tungsten wire njengempahla eluhlaza. Ucingo lwakhethwa ngenxa yamandla alo angavamile, indawo ephakeme yokuncibilika kanye nokumelana nokugqwala, okulwenza lufanelekele ukusetshenziswa ekusetshenzisweni kwezinga lokushisa eliphezulu. Ukukhipha intambo: Intambo ye-tungsten ekhethiwe ikhishiwe ukuze kuthuthukiswe i-ductility yayo futhi kube lula inqubo yokusonta elandelayo. I-Annealing ukushisisa intambo ibe izinga lokushisa eliphezulu bese ipholisa kancane, okusiza ukususa ingcindezi yangaphakathi futhi kwenza ucingo lube lukhuni kakhulu. Inqubo yokusonta: Intambo ye-tungsten ene-anneal isuke isontiwe ukuze yakhe isakhiwo somucu. Inqubo yokusonta ilawulwa ngokucophelela ukuze kuqinisekiswe ukuthi ubukhulu be-filament obudingekayo kanye nezakhiwo zemishini ziyafinyelelwa. Ukwelashwa kokushisa: Intambo ye-tungsten esontekile ingaphansi kwenqubo yokwelashwa kokushisa ukuze iqhubeke nokuthuthukisa izici zayo zokusebenza ezifana namandla kanye ne-ductility. Lesi sinyathelo singase sifake ukushisisa umcu kuzinga lokushisa elithile bese sipholiswa ngaphansi kwezimo ezilawulwayo ukuze kutholwe isakhiwo se-metallographic esifunekayo. Ukulawula Ikhwalithi Nokuhlola: Kuyo yonke inqubo yokukhiqiza, izinyathelo zokulawula ikhwalithi ziyasetshenziswa ukuze kuqinisekiswe ukuthi intambo ye-tungsten ihlangabezana nokucaciswa okudingekayo. Lokhu kungase kuhlanganise ukuhlola amandla emishini ye-filament, ukunemba kobukhulu kanye nezinye izici ezibalulekile. Ukucutshungulwa kokugcina: Uma imicu ye-tungsten isiphumelele ukuhlolwa kokulawulwa kwekhwalithi, ingase ibhekane nezinyathelo ezengeziwe zokucutshungulwa, njengokwelashwa kwendawo noma ukufakwa kokumboza, ukuze kuthuthukiswe ukusebenza kwazo ezinhlelweni ezithile.

Ukukhiqizwa kocingo olucijile lwe-tungsten kudinga amasu okukhiqiza anembayo kanye nokulawula ngokucophelela izakhiwo zezinto ezibonakalayo ukuze kuqinisekiswe ukuthi ucingo oluvelayo luhlangabezana nezimfuneko zokushisa okuphezulu kanye nezakhiwo zemishini ezidingekayo ekusetshenzisweni okufana nokukhiqizwa kwe-semiconductor.

Umcu we-tungsten osontekile uvame ukusetshenziswa kumalambu okukhanya kwe-incandescent nakwezinye izinhlelo zokusebenza zokukhanyisa ezihlukahlukene. Izakhiwo eziyingqayizivele ze-Tungsten, okuhlanganisa indawo yayo ephezulu yokuncibilika kanye nokuhamba kahle kwe-thermal, kuyenza ibe into efanelekile yamafilaments okumele imelane namazinga okushisa aphezulu kuyilapho igcina ubuqotho besakhiwo ngesikhathi sokusebenza. Kusibani sokukhanya kwe-incandescent, amandla kagesi adlula kumcu osontekile we-tungsten, okuwubangela ukuba ushise futhi ukhiphe ukukhanya okubonakalayo. Ukusonteka kwe-filament kusiza ukwandisa indawo yayo, okuvumela ukuchithwa kokushisa okuphumelelayo nokukhipha ukukhanya. Lo mklamo uphinde usize ukwandisa amandla nokuqina kwe-filament, ukuyivumela ukuthi imelane nezingcindezi ezishisayo nezomshini ezitholakala ngesikhathi sokusebenza. Intambo ye-Tungsten iphinde isetshenziswe ezintweni zokushisisa ezikhethekile, amadivaysi e-electron beam, kanye nezinhlobonhlobo zezinhlelo zokusebenza ezisezingeni eliphezulu lokushisa lapho ukumelana nokugqwala nokusebenza okungaguquki emazingeni okushisa aphezulu kubaluleke kakhulu.

Sekukonke, ukusetshenziswa kwentambo ye-tungsten eboshiwe kudlala indima ebalulekile ekunikezeni ukukhanya okuthembekile, okuphumelelayo nezixazululo zokushisa zezinhlelo zokusebenza ezihlukene zezimboni, ezentengiselwano, nezindawo zokuhlala.

| Igama Lomkhiqizo | I-Tungsten Twisted Filament |

| Okubalulekile | W1 |

| Ukucaciswa | Kwenziwe ngokwezifiso |

| Ubuso | ephucuziwe |

| Icebo | Sintering inqubo, machining |

| Iphuzu elincibilikayo | 3400 ℃ |

| Ukuminyana | 19.3g/cm3 |

Ingxoxo: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com