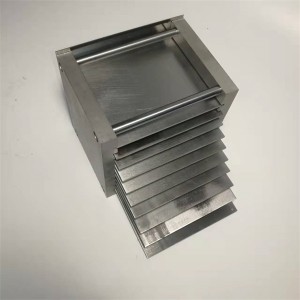

Ibhodwe elincibilikayo le-tungsten crucible yesithando somlilo esishisayo

I-Tungsten crucible iwuhlobo lomkhiqizo we-tungsten yensimbi, ikakhulukazi ihlukaniswe yaba izinhlobo ezimbili: i-sintering ne-stamping. Inqubo yokulungiselela i-tungsten crucible ihlanganisa uhlobo lokuphotha, uhlobo lokunyathela, njll. Lezi zinqubo zenza i-tungsten crucible ibe nokuminyana okuphezulu, ukuhwaqeka okuphansi kwendawo, amandla aqinile aqinile nobulukhuni, kuyilapho izindleko zokukhiqiza ziphansi, futhi intengo yomkhiqizo nayo iphansi kakhulu. .

Ukusetshenziswa okubanzi kwama-tungsten crucibles kuzuzisa ezakhiweni zawo ezinhle kakhulu zomzimba namakhemikhali, okuhlanganisa indawo ephezulu yokuncibilika, amandla aphezulu, ukumelana nokugqwala okuhle, nokumelana nokugqokwa. .

| Ubukhulu | Njengesidingo sakho |

| Le yindawo ka Origin | Luoyang, Henan |

| I gama le-brand | FGD |

| Isicelo | Imboni |

| Ubuso | Ipholishiwe |

| Ubumsulwa | 99.95% Min |

| Okubalulekile | I-tungsten ehlanzekile |

| Ukuminyana | 19.3g/cm3 |

| indawo yokuncibilika | 3400 ℃ |

| Indawo yokusetshenziswa | Vacuum imvelo |

| Izinga lokushisa lokusetshenziswa | 1600-2500 ℃ |

| Izingxenye eziyinhloko | W>99.95% |

| Okuqukethwe ukungcola≤ | |

| Pb | 0.0005 |

| Fe | 0.0020 |

| S | 0.0050 |

| P | 0.0005 |

| C | 0.01 |

| Cr | 0.0010 |

| Al | 0.0015 |

| Cu | 0.0015 |

| K | 0.0080 |

| N | 0.003 |

| Sn | 0.0015 |

| Si | 0.0020 |

| Ca | 0.0015 |

| Na | 0.0020 |

| O | 0.008 |

| Ti | 0.0010 |

| Mg | 0.0010 |

| Okubalulekile | 100% recrystallization lokushisa ℃ | (Isikhathi sokubhalisa: ihora eli-1)) |

|

| I-Deformation degree=90% | I-Deformation degree=99.99% |

| Okuhlanzekile W | 1350 | - |

| I-WVM | - | 2000 |

| WL10 | 1500 | 2500 |

| WL15 | 1550 | 2600 |

| WRe05 | 1700 | - |

| WRe26 | 1750 | - |

1. Imboni yethu itholakala eLuoyang City, esifundazweni saseHenan. I-Luoyang iyindawo yokukhiqiza yezimayini ze-tungsten ne-molybdenum, ngakho-ke sinezinzuzo eziphelele ngekhwalithi namanani;

2. Inkampani yethu inabasebenzi bezobuchwepheshe abaneminyaka engaphezu kwengu-15 yesipiliyoni, futhi sinikeza izixazululo neziphakamiso ezihlosiwe zezidingo zekhasimende ngalinye.

3. Yonke imikhiqizo yethu ihlolwa ngokuqinile ikhwalithi ngaphambi kokuthunyelwa kwamanye amazwe.

4. Uma uthola izimpahla ezingalungile, ungaxhumana nathi ukuze uthole imbuyiselo.

1. Lungisa i-tungsten powder

(Okokuqala, lungisa i-tungsten powder futhi uyihlole ukuze uhlukanise impushana ye-tungsten emahhadla necolekileyo)

2. Iqoqo elihlanganisiwe

(Ukucutshungulwa kwenqwaba ye-tungsten powder enokwakheka kwamakhemikhali okufanayo kodwa ezinqubweni ezihlukene zokukhiqiza)

3. ukucindezela isostatic

(Faka impushana ye-tungsten ehlanganisiwe esitsheni esivalekile esigcwele uketshezi, futhi kancane kancane uyicindezele ngohlelo lwe-pressurization ukuze unciphise ibanga phakathi kwama-molecule, ukhuphule ukuminyana, futhi uthuthukise izici ezibonakalayo zento ngaphandle kokushintsha ukubukeka kwayo)

4. Mabillet machining

(Ngemva kokuqeda ukucindezelwa kwe-isostatic, ukucutshungulwa kwe-billet rough kuyenziwa)

5. Intermediate frequency sintering

(Beka i-billet emaholoholo ecubunguliwe esithandweni somlilo esiphakathi nendawo ukuze isebenze)

6. Ukucubungula kahle kwemoto

(Ukuguqula umkhiqizo owenziwe nge-sintered ukuze uthole ubukhulu obunembile nomumo)

7. Hlola ukupakisha

(Hlola i-tungsten crucible ecutshunguliwe bese uyipakisha ngemva kokuphumelela ukuhlolwa)

Ukuncibilika kwengilazi ye-quartz: Izingcwecwe ze-Tungsten nazo zisetshenziswa kakhulu kumaziko okuncibilikisa ingilazi ye-quartz. Njengenye yemishini ebalulekile yokuncibilikisa ingilazi yequartz, amandla azo okushisa aphezulu kanye nokumelana nokugqwala kwenza ingilazi ye-quartz incibilike futhi yakhe isimo esifiswayo ezindaweni zokushisa okuphezulu.

Ukuguqulwa kwe-crucible kubangelwa ukwanda okungalingani kwezingxenye ezahlukene ze-crucible ngenxa yokushisa ngokweqile nokungalingani. Ukushisisa okusheshayo nokungalingani kwe-crucible kufanele kugwenywe.

Ibanga lokushisa elinconyiwe lingu-1600-2500 degrees Celsius.