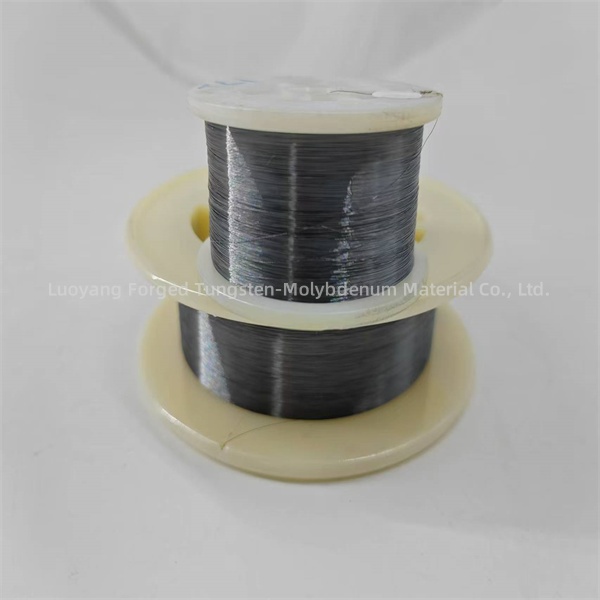

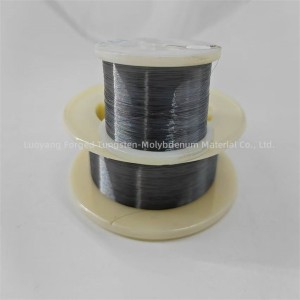

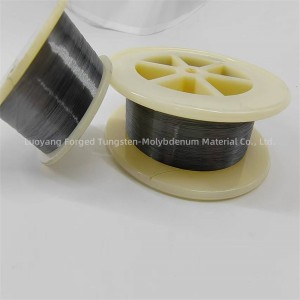

I-W1 ehlanzekile engu-0.18 ye-tungsten wire EDM yokusika

Yebo, i-EDM yocingo (imishini yokukhipha ugesi) ingasetshenziselwa ukusika i-tungsten. I-Tungsten iyinto eqinile, encibilika kakhulu engaba inselele ukuyisika usebenzisa izindlela zokucubungula zendabuko. Kodwa-ke, imishini ye-EDM yocingo ilungele ukusika i-tungsten ngenxa yekhono labo lokusika ngokunembile ubujamo obuyinkimbinkimbi ezintweni ezinzima.

Ku-EDM yocingo, i-wire conductive encane (evame ukwenziwa ngethusi noma i-tungsten) isetshenziselwa ukusika umsebenzi. Lapho usika i-tungsten usebenzisa i-EDM yocingo, kubalulekile ukucabangela izici ezilandelayo:

1. Ukukhetha intambo: Intambo ye-Tungsten ingasetshenziswa njengocingo lokusika emshinini wokukhipha ugesi osikwe ngocingo ukusika izinto eziqinile ezifana ne-tungsten. Intambo ye-Tungsten yakhethwa ngenxa yamandla ayo aphezulu aqinile nokumelana nokushisa nokuhuzuka.

2. Izilungiselelo zamandla: Umshini wakho we-EDM udinga ukusethwa kuzilungiselelo zamandla ezifanele ukuze kuqinisekiswe ukukhishwa okusebenzayo okusebenzayo kuyilapho ugcina ubuqotho be-tungsten filament.

3. Hlanza futhi ukhiphe imfucumfucu: Uma usika i-tungsten, ukugezwa okufanele kanye nokususwa kwemfucumfucu ye-workpiece kubalulekile ukuze kugcinwe ukunemba kokusika nokuvimbela ukuphuka kwezintambo.

4. I-wire Tension kanye ne-Threading: Ukucindezelwa okufanele nokucushwa kocingo lwe-tungsten kubalulekile ukuze kuzuzwe imiphumela yokusika enembile nengaguquguquki.

Lapho usika i-tungsten ngomshini we-EDM wocingo, kubalulekile ukulandela imikhuba emihle futhi ucabange izici ezithile ze-tungsten ukuze uzuze imiphumela engcono kakhulu yokusika.

Ukujiya kwentambo yokusika kwe-EDM (Electrical Discharge Machining) kungahluka kuye ngohlelo oluthile nezinto ezicutshungulwayo. Ngokuvamile, ububanzi bocingo lwe-EDM ngokuvamile bungu-0.1 mm ukuya ku-0.3 mm (0.004 intshi kuya ku-0.012 intshi). Nokho, intambo ewugqinsi noma ezacile ingase isetshenziselwe izinhlelo ezithile.

Ngokusikeka okumahhadlahhadla noma ukususwa kwempahla ngokushesha, izintambo eziqinile (0.25 mm kuya ku-0.3 mm) zingakhethwa. Intambo ewugqinsi ingakwazi ukuphatha imisinga ephezulu futhi ingcono ekususeni izinto ngokushesha.

Ngokusikeka okuhle, izimo eziyinkimbinkimbi, noma ukubekezelelana okuqinile, izintambo ezincanyana (0.1 mm kuya ku-0.2 mm) zivame ukusetshenziswa. Intambo ezacile ivumela ukusikeka okunembe kakhudlwana nokunemininingwane, iyenze ifaneleke izinhlelo zokusebenza ezidinga ukunemba okuphezulu.

Uma ukhetha ukujiya kwezintambo zokusika i-EDM, izici ezifana nezinto ezicutshungulwayo, isivinini sokusika esidingekayo kanye nokuqedwa kwendawo okudingekayo kufanele kucatshangelwe. Ukwengeza, amakhono athile omshini we-EDM kanye nezincomo zomkhiqizi kufanele kucatshangelwe lapho kunqunywa ukujiya kwezintambo ezifanele zohlelo olunikeziwe.

Ingxoxo: 15138768150

WhatsApp: +86 15838517324

E-mail : jiajia@forgedmoly.com