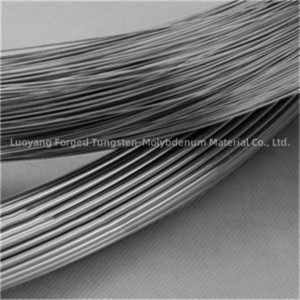

I-Molybdenum wire yokusika i-EDM (Electrical Discharge Machining).

Ukukhiqizwa kwentambo ye-molybdenum yokusika i-EDM (Electrical Discharge Machining) kuhilela izinyathelo ezimbalwa ezibalulekile, ngasinye sibalulekile ekuqinisekiseni ikhwalithi ephezulu yocingo, ukunemba, nezici zokusebenza. Nakhu ukubuka konke kwenqubo yokukhiqiza ejwayelekile:

I-Molybdenum Powder Production

Ukuhlanzwa: I-molybdenum ore iyahlanzwa ukuze ikhiqize i-molybdenum oxide, ebuye yehliselwe ku-molybdenum powder.

Ukuhlanganisa: Impushana ihlanganiswa ukuze kuzuzwe ukwakheka kwamakhemikhali okufunayo.

I-Powder Metallurgy

Ukucindezela: I-molybdenum powder icindezelwa ibe ifomu elihlanganisiwe ngaphansi kwengcindezi ephezulu.

I-Sintering: Impushana ehlanganisiwe ishiswa esithandweni esingaphansi kwendawo yayo yokuncibilika ukuze ihlanganise izinhlayiya ndawonye, yenze inqwaba eqinile.

Metal Umdwebo

I-Swaging/Hot Drawing: I-molybdenum e-sintered ekuqaleni yakheka ibe yizinduku ngomdwebo oshisayo noma inqubo yokugubha, enciphisa ububanzi bayo futhi ikhulise ubude bayo ngaphandle kokushintsha ivolumu yayo.

Umdwebo Wocingo: Izinti ziphinde zidwetshwe ngochungechunge lwama-dies ukuze kuncishiswe kancane kancane ububanzi bawo bufinyelele kusayizi oyifunayo wentambo ye-EDM. Le nqubo yenziwa ngaphansi kwezimo ezilawulwayo ukuvimbela ukuphuka kwezintambo nokuqinisekisa ububanzi obufanayo.

Ukuhlanza kanye nokuhlanza

Ukuhlanza: Intambo edonsayo iyahlanzwa ukuze kukhishwe noma yiziphi izinto zokuthambisa, ama-oxide, noma okunye ukungcola endaweni yayo.

I-Annealing: Intambo ibe isinqanyulwa, inqubo yokwelapha ukushisa ekhulula ukucindezeleka kwangaphakathi okubangelwa ngesikhathi sokudweba, okuthuthukisa ukudubeka kwayo kanye nokuhamba kukagesi.

Ukuhlola kanye Ukupakisha

Ukulawulwa Kwekhwalithi: Intambo yokugcina ibhekana nokuhlolwa kokulawula ikhwalithi okuqinile ukuze kuqinisekiswe ububanzi bayo, amandla aqinile, ikhwalithi ephezulu, kanye nezakhiwo zikagesi.

I-Spooling and Packaging: Uma isigunyaziwe, intambo ihlanganiswa kumareel anobude obucacisiwe futhi ipakishwe ukuze ithunyelwe, okuqinisekisa ukuvikeleka emonakalweni nokungcoliswa.

Le nqubo yokukhiqiza ilawulwa ngokucophelela futhi iqashwe ukuze kuqinisekiswe ukuthi intambo ye-molybdenum ihlangabezana nezidingo eziqinile ezidingekayo ukuze kusetshenziswe izinhlelo zokusebenza zokusika ze-EDM eziphumelelayo nezinembile.

Precision Metal Cutting

IJiyometri Eyinkimbinkimbi: Ilungele ukusika izimo eziyinkimbinkimbi nezici ezinhle ezinsimbi eziqinile nama-alloys okunzima ukuwenza ngomshini ngezindlela zendabuko.

Ukubekezelela Okuqinile: Kunika amandla ukukhiqizwa kwezingxenye ezinemba okuphezulu nokubekezelelana okuqinile, okubalulekile ku-aerospace, izimboni zezimoto, nezimboni zobunjiniyela ezinembayo.

Ukwenza isikhunta kanye nokufa

Ukukhiqiza Isikhunta: Isetshenziswa ekukhiqizeni isikhunta sokubumba umjovo wepulasitiki, ukubunjwa kwe-die cast, kanye nokwakha, okuvumela ukwakhiwa kwemiklamo yesikhunta enemininingwane neyinkimbinkimbi.

I-Die Manufacturing: Ibalulekile ekwenzeni izitembu ziyafa, i-extrusion dies, nezinye izinhlobo zokufa ezisetshenziswa ezinqubweni zokwakhiwa kwensimbi.

I-Aerospace ne-Automotive Components

Izingxenye ze-Aerospace: Ikhiqiza izingxenye ezinamandla nokunemba okudingekayo ezinhlelweni ze-aerospace, okuhlanganisa izingxenye zenjini, izingxenye zegiye lokumisa, nezinsimbi.

Izingxenye Zezimoto: Isetshenziselwa ukukhiqiza izingxenye zezimoto ezibalulekile, njengamabhomu omjovo, izingxenye zebhokisi lamagiya, kanye nezingxenye ezinejometri eyinkimbinkimbi.

Ukwenziwa Kwedivayisi Yezokwelapha

Izinsimbi Zokuhlinza: Inika amandla ukudalwa kwamathuluzi okuhlinza ayinkimbinkimbi namadivayisi, azuza ekhonweni lentambo lokukhiqiza ukusikeka okunembile nomumo.

Izimila: Ilungele ukwenza izimila zezokwelapha ezidinga ukunemba okuphezulu kanye nokuvumelana kwe-biocompatibility.

Imboni yezogesi kanye ne-semiconductor

Izisetshenziswa zeSemiconductor: Zisetshenziswa ekukhiqizeni amadivaysi e-semiconductor nezingxenye, lapho ukunemba nobuqotho bezinto ezibonakalayo kubaluleke kakhulu.

Ukukhiqizwa Kwebhodi Lesifunda: Isiza ekukhiqizeni amabhodi esekethe aphrintiwe (ama-PCB) namadivayisi e-microelectronic, okuvumela ukudalwa kwamaphethini amahle nemininingwane.

Ukuguquguquka kwe-Molybdenum wire kanye nezakhiwo eziphakeme kukwenza kube ukukhetha okuncanyelwayo kwe-EDM ukusika kuzo zonke lezi zinhlelo zokusebenza ezihlukene, ukushayela ukuqamba okusha nokunemba ekukhiqizeni.

| Ukucaciswa | Incazelo |

|---|---|

| Ububanzi | 0.1mm - 0.3mm (osayizi abajwayelekile) |

| Okubalulekile | I-Molybdenum ehlanzekile |

| I-Melting Point | Cishe ku-2623°C (4753°F) |

| Amandla Okuqina | 700-1000 MPa (kuye ngokuthi ububanzi) |

| I-Electric Conductivity | Phezulu |

| I-Surface Qeda | Bushelelezi, buhlanzekile, ngaphandle kwamaphutha |

| Usayizi we-Spool | Iyahlukahluka (isb, 2000m, 2400m nge-spool ngayinye) |

| Isicelo | Ifanele ukusika okuphezulu kwe-EDM |

| Izici | Ukuqina okuphezulu, ukusebenza kahle ekusikeni |

| Ukuhambisana | Ihambisana nemishini ehlukahlukene ye-EDM |

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com