I-molybdenum round rod ye-High-temperature sintering kanye nemboni yokwelapha ukushisa

Ukwelashwa kokushisa kwe-molybdenum ngokuvamile kuhilela izinqubo ezithuthukisa izakhiwo zayo zokuzilungisa njenge-ductility, ukuqina, namandla. Izinqubo ezivame kakhulu zokwelashwa kokushisa kwe-molybdenum zifaka ukuncishiswa nokukhululeka kwengcindezi:

1. Ukufakwa kwe-Annealing: I-Molybdenum ivamise ukudonswa ukuze kuncishiswe ubulukhuni bayo futhi kwandise i-ductility yayo. Inqubo yokuthungatha ngokuvamile ihilela ukushisisa i-molybdenum ezingeni lokushisa elithile (imvamisa engaba ngu-1200-1400°C) bese ipholiswa kancane kancane ifike kuzinga lokushisa elilingana negumbi. Le nqubo isiza ukukhulula ukucindezeleka kwangaphakathi futhi iphinde ihlanganise isakhiwo se-molybdenum, ithuthukise i-ductility nokuqina.

2. Ukunciphisa ingcindezi: Izingxenye ze-Molybdenum eziye zabhekana nokusebenza okubandayo noma ukwenziwa kwemishini zingadambisa ingcindezi ukuze kuncishiswe ingcindezi yangaphakathi futhi kuthuthukiswe ukuzinza kwe-dimensional. Inqubo ihilela ukushisisa i-molybdenum ezingeni lokushisa elithile (imvamisa engaba ngu-800-1100°C) nokuyibamba kulelo zinga lokushisa isikhathi esithile ngaphambi kokuyipholisa kancane. Ukunciphisa ingcindezi kusiza ukunciphisa ukuhlanekezela futhi kunciphise ingozi yokuqhekeka kwezakhi ze-molybdenum.

Kuyaqapheleka ukuthi inqubo ethile yokwelashwa kokushisa kwe-molybdenum ingahluka kuye ngokuthi ukwakheka kwe-alloy, ukusetshenziswa okuhlosiwe kanye nezinto ezibonakalayo ezifiselekayo. Ngakho-ke, kunconywa ukuthi uthintane nochwepheshe bezinto ezibonakalayo noma ubheke imihlahlandlela ethile yokwelapha ukushisa kwe-molybdenum ukuze uqinisekise ukwelashwa okufanele kwesicelo esinikeziwe.

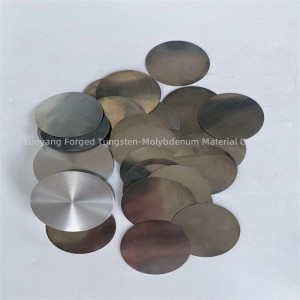

Ukucwiliswa kwe-molybdenum kuhilela inqubo yokuhlanganisa impushana ye-molybdenum futhi iyishisise ezingeni lokushisa elingaphansi kwendawo yayo yokuncibilika, okubangela ukuthi izinhlayiya zempushana zihlangane ndawonye. Le nqubo iphumela ekwakhekeni kwesakhiwo se-molybdenum esiqinile esinamandla athuthukisiwe kanye nokuminyana.

Inqubo ye-sintering ngokuvamile ihlanganisa izinyathelo ezilandelayo:

1. Ukucindezela i-Powder: Sebenzisa isikhunta noma i-die ukuze ucindezele impushana ye-molybdenum ibe yisimo oyifunayo. Inqubo yokuhlanganisa isiza ukwakha isakhiwo esivumelanayo sibe yimpushana.

2. Ukushisisa: Impushana ehlanganisiwe ye-molybdenum ibe isishisiswe endaweni elawulwayo ibe izinga lokushisa elingaphansi kwendawo yokuncibilika ye-molybdenum. Lokhu kushisa kuvame ukuphakama ngokwanele ukuze izinhlayiya zempushana zihlangane ndawonye ngokusakazwa, kwakhiwe isakhiwo esiqinile.

3. Ukuminyana: Phakathi nenqubo yokucwilisa, ukwakheka kwe-molybdenum kuminyene njengezinhlayiya ezihlangene ndawonye. Lokhu kubangela ukuminyana okukhulu namandla ezingxenye ze-sintered molybdenum.

I-Sintering ivame ukusetshenziselwa ukukhiqiza izingxenye ze-molybdenum ezinezimo eziyinkimbinkimbi kanye nezidingo eziphezulu zokuminyana, ezifana nezakhi zokushisa, izingxenye zesithando somlilo, izikebhe ezishisayo, njll. Le nqubo ikhiqiza izingxenye ze-molybdenum ezinamandla neziqinile ezinezakhiwo ezithuthukisiwe zemishini ezifanele izicelo zokushisa okuphezulu.

Ingxoxo: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com