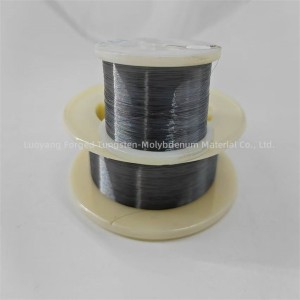

i-molybdenum indilinga ye-molybdenum eyindilinga ye-molybdenum efakwe ngomshini ingxenye

Yebo, i-molybdenum ithathwa njengento enzima ukuyisika ngenxa yokuqina kwayo okuphezulu nokuqina. Ubulukhuni bayo kanye nokumelana nokuguqulwa kwenza kube nzima umshini usebenzisa amathuluzi okusika endabuko kanye namasu. Ukwengeza, indawo ephezulu yokuncibilika kwe-molybdenum kanye nokuthambekela kokusebenza kanzima kuyathuthukisa futhi idumela layo njengento yokusika eyinselele.

Ukuze ngokuphumelelayo i-molybdenum yomshini, amathuluzi okusika akhethekile, imingcele yokucubungula kanye namasu avame ukudingeka. Isibonelo, ukusebenzisa amathuluzi okusika i-carbide noma i-polycrystalline diamond (PCD), kanye nesivinini esifanelekile sokusika, amasu okuphakelayo nawokupholisa, kungasiza ukuthuthukisa ukusebenza kahle kwe-molybdenum.

Ukwengeza, kwezinye izinhlelo zokusebenza ze-molybdenum, ikakhulukazi lapho kucutshungulwa izimo eziyinkimbinkimbi noma izingxenye ezinembe kakhulu, izinqubo ezithuthukisiwe zokwenza imishini ezifana ne-electrical discharge machining (EDM) noma i-laser cutting zingakhethwa.

Sekukonke, nakuba ubulukhuni nokuqina kwe-molybdenum iletha izinselele zomshini, ngamathuluzi afanele namasu, ingenziwa ngomshini ngempumelelo ukuze kukhiqizwe izingxenye zekhwalithi ephezulu zezinhlobonhlobo zezimboni, i-aerospace, nezinhlelo zokusebenza zesayensi .

I-Molybdenum ngokuvamile ibhekwa njengensimbi ye-ductile. Ine-degree of malleability eyivumela ukuthi yakheke, yakheke futhi idwetshwe ezinhlobonhlobo zomumo nezingxenye. Le ductility ingumphumela we-molybdenum's metallic bonding kanye ne-crystal structure, eyivumela ukuthi ikhubazeke ngaphansi kwezimo ezithile ngaphandle kokuphuka.

Kodwa-ke, kufanelekile ukuqaphela ukuthi i-ductility ye-molybdenum ingathinteka yizici ezifana nezinga lokushisa, ukungcola kanye nokuba khona kokukhubazeka. Emazingeni okushisa aphansi nangaphansi kwezimo ezithile, i-molybdenum ingaba brittle, ikakhulukazi uma ishintsha ngokushesha noma kanzima.

Eqinisweni, i-ductility ye-molybdenum iyenza ifanele izinqubo ezihlukahlukene zokwakha nokukhiqiza, okuhlanganisa ukugoqa, ukufoja nokudweba. Kodwa-ke, njengezinsimbi eziningi, i-ductility ye-molybdenum ingaphazanyiswa izimo zokucubungula kanye nezici zemvelo.

Yebo, i-molybdenum ingagotshwa, kodwa ngenxa yamandla ayo aphezulu nobulukhuni, imishini ekhethekile namasu ayadingeka. Inqubo yokugoba i-molybdenum ngokuvamile ihilela ukusebenzisa amandla alawulwayo ukuze kukhubaze insimbi ibe yisimo osifunayo ngaphandle kokuyenza iphuke noma iqhekeke.

Ukuze igobe ngempumelelo i-molybdenum, ivamise ukushiselwa emazingeni okushisa aphezulu ukuze inciphise amandla ayo futhi ikhulise i-ductility yayo, iyenze ibe lula futhi kulula ukuyikhubaza. Le nqubo, ebizwa ngokuthi ukugoba okushisayo, ingenza i-molybdenum ibe yizimo ezihlukahlukene, njengezinduku, amashidi nezingxenye zangokwezifiso.

Ukugoba okubandayo kwe-molybdenum, okubandakanya ukubumba insimbi ekamelweni lokushisa, nakho kungenzeka, kodwa kudinga amandla abalulekile namathuluzi akhethekile ukuze kuzuzwe ukugoba okufunayo ngaphandle kokubangela imifantu noma okunye ukukhubazeka.

Ezilungiselelweni zezimboni nezokukhiqiza, i-molybdenum ivamise ukusetshenziselwa ukwenza izingxenye zezinhlelo zokusebenza ezikhethekile, njengezimboni ze-aerospace, electronics, kanye ne-semiconductor. Kodwa-ke, ngenxa yemvelo yayo eyinselele, i-molybdenum yokugoba kufanele yenziwe ochwepheshe abanolwazi besebenzisa imishini efanele kanye nezinyathelo zokuphepha ukuze kuqinisekiswe ubuqotho bensimbi kanye nekhwalithi yomkhiqizo ophelile.

Ingxoxo: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com