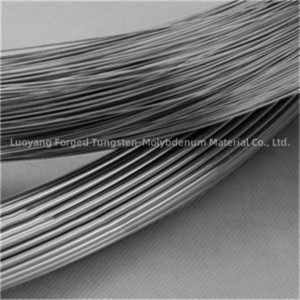

intambo ye-tungsten eyenziwe ngokwezifiso yokugqoka i-vacuum

Indlela yokukhiqiza ye-tungsten wire yokugcoba i-vacuum ngokuvamile ihlanganisa lezi zinyathelo ezilandelayo:

Ukukhetha impahla eluhlaza: Khetha impushana ye-tungsten yekhwalithi ephezulu njengempahla eluhlaza yokukhiqiza intambo ye-tungsten. Ukuxutshwa kwempushana: Impushana ye-Tungsten ixutshwa nezibophezelo nezinye izithasiselo ukuze kwakhiwe ingxube ye-homogeneous, bese icindezelwa ibe yifomu eliqinile kusetshenziswa ubuchwepheshe bokucindezela. I-Sintering: Ingxube ye-tungsten ehlanganisiwe ingaphansi kwamazinga okushisa aphezulu endaweni elawulwayo ukuze ifake izinhlayiya ndawonye ukuze zakhe intambo ye-tungsten eqinile. Umdwebo: Intambo ye-tungsten e-sintered ibe isidwetshwa ngochungechunge lwama-dies ukuze kutholwe ububanzi obufunekayo kanye nokuqedwa kwendawo okubushelelezi. I-Annealing: Intambo ye-tungsten edwetshiwe ingabanjwa (inqubo yokwelapha ukushisa) ukuze kwandiswe i-ductility yayo futhi iqede noma yikuphi ukucindezeleka okusalayo. Ukwelapha Okungaphezulu: Intambo ye-Tungsten ingaba nokwelashwa okwengeziwe kwendawo, njengokuhlanza, ukupholishwa noma ukunamathiswa, ukuze kuthuthukiswe ukufaneleka kwayo kwezinhlelo zokusebenza ze-vacuum coating.

Lezi zinyathelo zingase zihluke kuye ngezidingo ezithile zenqubo ye-vacuum coating kanye nezakhiwo ezifunwayo ze-tungsten filament.

Intambo ye-Tungsten ivame ukusetshenziswa ezinqubweni zokumboza i-vacuum ngenxa yephuzu layo eliphezulu lokuncibilika, ukuqhutshwa kwe-thermal okuhle kakhulu, nokucindezela komhwamuko ophansi emazingeni okushisa aphezulu. Uma isetshenziswa njengento yokushisisa noma i-filament ohlelweni lokumboza i-vacuum, i-tungsten filament ingakhiqiza ngempumelelo ukushisa ukuze kuhwamuke izinto zokumboza njengezinsimbi noma izitsha zobumba. Le nqubo yokuhwamuka ibangela ukuthi izinto zokumboza zifakwe ngokulinganayo endaweni engaphansi kwe-substrate, zenze ukunamathela okuncane, okufanayo. Ikhono le-Tungsten wire ukugcina ubuqotho besakhiwo kanye nokumelana nokuguquka emazingeni okushisa aphezulu kuyenza ifaneleke ezinhlelweni zokufaka i-vacuum coating, lapho ukulawulwa kwezinga lokushisa nokuzinza kubalulekile ukuze kuzuzwe imiphumela engaguquki yokuhlanganisa. Ngaphezu kwalokho, ukucindezela komhwamuko ophansi we-tungsten kuqinisekisa ukungcoliswa okuncane kwendawo ye-vacuum ngesikhathi sokushisisa nokuhwamuka.

Sekukonke, izici eziqinile ze-tungsten wire kanye nokumelana nezinga lokushisa eliphezulu kuyenza ibe ukukhetha okuthembekile kumasistimu wokuvala i-vacuum, okusiza ukukhiqiza ikhwalithi ephezulu, ukunamathela okufanayo ezinhlotsheni ze-substrate ehlukahlukene.

| Igama Lomkhiqizo | I-Tungsten wire yokugqoka i-vacuum |

| Okubalulekile | W1 |

| Ukucaciswa | Kwenziwe ngokwezifiso |

| Ubuso | Isikhumba esimnyama, i-alkali egeziwe, epholishiwe. |

| Icebo | Sintering inqubo, machining |

| Iphuzu elincibilikayo | 3400 ℃ |

| Ukuminyana | 19.3g/cm3 |

Ingxoxo: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com