Ibhola ye-tungsten ephezulu, iintsimbi zokuloba zeTungsten

I-Molybdenum crucibles idla ngokuveliswa kusetyenziswa enye yeendlela ezimbini eziphambili zokuvelisa: I-metallurgy yomgubo: Le ndlela ibandakanya ukuxuba umgubo we-molybdenum, ukuyicinezela kwimilo enqwenelekayo ye-crucible, kwaye emva koko ufaka umgubo odibeneyo kwi-vacuum ephezulu yobushushu okanye umoya we-hydrogen. Le nkqubo inceda ukufezekisa ubuninzi obufunekayo kunye nokunyaniseka kwesakhiwo se-crucible. Ukutshiza: Kule ndlela, intonga ye-molybdenum okanye intonga isetyenzisiwe usebenzisa izixhobo zokusika kunye nezixhobo ze-CNC ukukrola imilo enqwenelekayo ye-crucible. Le ndlela isoloko isetyenziselwa ukuvelisa iicrucible ezincinci okanye ezimile ngokwesiko. Kuzo zombini iimeko, iinkqubo ezongezelelweyo ezifana nokuphathwa kokushisa, ukugqitywa kwendawo, kunye nokuhlolwa kokulawulwa komgangatho kunokwenziwa ukuze kuqinisekiswe ukuba i-crucible yokugqibela idibana neenkcukacha ezifunekayo. Ezi nkqubo zivelisa umgangatho ophezulu we-molybdenum crucibles ezifanelekileyo kwizicelo ezahlukeneyo zokushisa, ezifana nokunyibilika kunye nokuphosa isinyithi, i-ceramics ye-sintering, kunye nezinye iinkqubo zonyango lokushisa.

I-Molybdenum crucibles isetyenziswa ngokubanzi kwizicelo zokushisa okuphezulu, ngakumbi kumashishini afana ne-metallurgy, imveliso yeglasi kunye ne-sintering material. Nazi ezinye iindlela zokusetyenziswa okuthe ngqo: Ukunyibilikiswa nokusatywa: Izikhonkwane ze-molybdenum zihlala zisetyenziselwa ukunyibilikisa nokujula iintsimbi ezinobushushu obuphezulu kunye nengxubevange njengegolide, isilivere, neplatinam. Iqondo eliphezulu lokunyibilika kwe-Molybdenum kunye ne-thermal conductivity egqwesileyo yenza ukuba ibe yinto efanelekileyo yokumelana nokushisa okugqithisileyo okubandakanyekayo kwinkqubo yokunyibilika kwesinyithi. I-Sintering: Ii-crucibles ze-Molybdenum zisetyenziselwa ukucoca i-ceramic kunye ne-powders yensimbi, apho amaqondo okushisa aphezulu afunekayo ukuphumeza ukuxinana kunye nokukhula kweenkozo. I-inertness ye-Molybdenum kunye nokukwazi kwayo ukumelana nobushushu obuphezulu ngaphandle kokuphendula kunye nezinto ezicutshungulwayo zenza kube yinto efanelekileyo yokukhetha izicelo ze-sintering. Ukwenziwa kweglasi: Iibhobho ze-molybdenum zisetyenziselwa ukuveliswa kweeglasi ezikhethekileyo kunye neeramics zeglasi. Ukuzinza okuphezulu kwe-thermal ye-Molybdenum kunye nokungangenisi kuqinisekisa ukuba ayingcolisi izinto ezinyibilikayo, okwenza kube yinto ebalulekileyo yenkqubo yokwenza iglasi. Ukuveliswa kwe-Semiconductor: Kwishishini le-semiconductor, i-molybdenum crucibles isetyenziselwa ukukhula kunye nokucubungula i-crystals enye, njenge-silicon kunye nezinye izinto ze-semiconductor. Ukucoceka okuphezulu kunye nokuchasana nokusebenza kweekhemikhali kwenza ukuba i-molybdenum ilungele ezi zicelo. Ngokubanzi, i-molybdenum crucibles ixabiswa ngenxa yokumelana nobushushu obuphezulu, ukunganyangeki kweekhemikhali, kunye nokuqina, okubenza babaluleke kwiinkqubo ezahlukeneyo zoshishino kunye nezenzululwazi ezibandakanya izinto ezishushu kakhulu kunye nezisebenzayo.

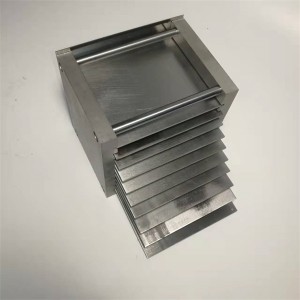

| Igama lemveliso | Ilabhoratri ye-Mo1 isebenzisa i-molybdenum crucible purity 99.95% |

| Izinto eziphathekayo | Mo1 |

| Inkcazo | Customized |

| Umphezulu | Ulusu olumnyama, ialkali ihlanjiwe, igudisiwe. |

| Ubuchwephesha | Inkqubo ye-Sintering, machining (i-tungsten rod hollowing processing) |

| Indawo yokunyibilika | 2600℃ |

| Ukuxinana | 10.2g/cm3 |

Wechat: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com