Molybdenum mandrel iplagi yokugqobhoza umbhobho yentsimbi engenamthungo

Ukuveliswa kweeplagi ze-molybdenum mandrel ngokuqhelekileyo kubandakanya indibaniselwano ye-machining, ukwenza isinyithi kunye neenkqubo zokugqiba. Oku kulandelayo ngamanyathelo aqhelekileyo abandakanyekayo kwindlela yokuvelisa:

Ukukhetha izinto ezikrwada: Khetha umgangatho ophezulu weentonga ze-molybdenum okanye iintonga njengemathiriyeli ekrwada yokuveliswa kweeplagi ze-mandrel. I-Molybdenum yakhethwa ngenxa yendawo ephezulu yokunyibilika, amandla kunye nokumelana nokubola, okwenza ukuba ilungele izicelo ezifuna ukushisa okuphezulu kunye neempawu zoomatshini. Machining: Intonga molybdenum ngoomatshini ukwenza imilo yokuqala iplagi mandrel. Oku kunokubandakanya ukujika, ukungqusha okanye ukugrumba ukufumana imilinganiselo efunekayo kunye neempawu zomhlaba. I-CNC (ulawulo lwamanani ekhompyutheni) ivumela ukubunjwa okuchanekileyo kunye nokusika. Metal Ukuqulunqa: A ngoomatshini molybdenum blank ke ixhomekeke kwinkqubo yokwenza isinyithi ezifana ukugoba, swaging okanye extrusion ukudala iimpawu ezithile kunye contours iplagi mandrel. Ngokomzekelo, ukuba i-tapered okanye i-conical shape iyadingeka kwiplagi ye-mandrel, iindlela zokwenza isinyithi zisetyenziselwa ukufikelela kwijometri efunekayo. Unyango lobushushu: Emva kokuqulunqa kunye nokubunjwa, iplagi ye-molybdenum mandrel inokungena kwinkqubo yonyango yokushisa ukunyusa iimpawu zayo zoomatshini ezifana namandla kunye nokuqina. Ukushisa okuphezulu kwe-annealing okanye i-sintering ingasetyenziselwa ukwandisa i-microstructure kunye nokuphelisa uxinzelelo olushiyekileyo. UKUGQIBELA: Iiplagi ze-Molybdenum mandrel ziqhuba umsebenzi wokugqiba ukuqinisekisa ukuchaneka komgangatho, ukugudisa komphezulu kunye nokuphelisa naziphi na iziphene. Oku kunokubandakanya ukupolisha, ukugaya okanye ezinye iindlela zokulungisa umphezulu ukuze kuphunyezwe ukugqitywa komphezulu ofunekayo kunye nokunyamezela kwejometri. Ukulawulwa komgangatho: Kuyo yonke inkqubo yokuvelisa, amanyathelo okulawula umgangatho aphunyezwa ukuhlola kunye nokuqinisekisa ukuchaneka komgangatho, ukunyaniseka kwezinto eziphathekayo kunye nomgangatho jikelele weeplagi ze-molybdenum mandrel. Iindlela zovavanyo ezingonakalisiyo, i-dimensional metrology kunye nokuhlolwa okubonakalayo kunokusetyenziswa ukuqinisekisa ukuthotyelwa kwemigaqo. Ngokulandela la manyathelo emveliso, abavelisi banokuvelisa iiplagi ze-molybdenum mandrel ezineempawu kunye neempawu zokusebenza ezifunekayo kwisicelo sabo.

Iiplagi zeMolybdenum mandrel ziqhele ukusetyenziswa kumbhobho ongenamthungo kunye neshishini lokuvelisa umbhobho. Ezi plugs zifakwe kwi-workpieces engenanto (iityhubhu okanye imibhobho) ngexesha lenkqubo yokuvelisa ukuqinisekisa ukuchaneka kobukhulu kunye nokuthintela iziphene ezifana ne-ovality okanye ukugungqa. Isixhobo se-molybdenum sikhethwe ngenxa yamandla aphezulu kumaqondo aphezulu, ukuchasana nokubola, kunye nokukwazi ukumelana nokushisa okuphezulu kunye noxinzelelo olubandakanyekayo kwinkqubo yokuvelisa umbhobho. izicelo ezithile iiplagi molybdenum mandrel zibandakanya: Imveliso umbhobho ingenamthungo: iiplagi Molybdenum mandrel zisetyenziswa kwimveliso imibhobho ingenamthungo njengezixhobo ezenza ukugcina ububanzi ngaphakathi kunye nomgangatho womphezulu workpiece. Ezi iiplagi mandrel zibalulekile ukukhokela nokuxhasa workpiece ukufikelela imilinganiselo efunwayo kunye nokugqiba umphezulu njengoko ingena thermal ukugqobhoza, ukolula kunye neenkqubo zokuqengqeleka. I-Hot rolling kunye nokubhoboza: Ngexesha lokutshisa kunye nokubhoboza inkqubo, iiplagi ze-molybdenum mandrel zisetyenziselwa ukuthintela ukubunjwa kwemibimbi, i-eccentricity kunye neziphene zomhlaba kwimibhobho engenamthungo. Ngokubonelela ngenkxaso yangaphakathi kunye nokubunjwa, iiplagi ze-mandrel zinceda ukuqinisekisa ukuveliswa komgangatho ophezulu, iimveliso ezifanayo kunye nemilinganiselo ehambelanayo. Ubume bobushushu obuphezulu: Ukusebenzisa iiplagi ze-molybdenum mandrel kunenzuzo ngokukodwa kwiindawo zokuvelisa ubushushu obuphezulu, apho indawo ephezulu yokunyibilika kwezinto kunye neempawu ezibalaseleyo ze-thermal zivumela ukuba zimelane neemeko ezinzima ezidibana nazo ngexesha lokuvelisa umbhobho.

Ngokubanzi, iiplagi ze-molybdenum mandrel zidlala indima ephambili ekuqinisekiseni ukuchaneka kwe-dimensional, umgangatho ophezulu kunye nengqibelelo ye-tubing engenamthungo, ekugqibeleni inceda ukuvelisa ukusebenza okuphezulu kumashishini ahlukeneyo afana neenqwelo, i-aerospace, i-oyile kunye negesi, njl isebe lemveliso.

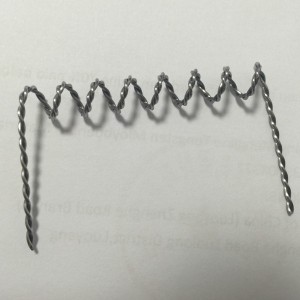

| Igama lemveliso | Molybdenum mandrel iplagi |

| Izinto eziphathekayo | Mo |

| Inkcazo | Customized |

| Umphezulu | Ulusu olumnyama, ialkali ihlanjiwe, igudisiwe. |

| Ubuchwephesha | inkqubo Sintering, machining |

| Indawo yokunyibilika | 2600℃ |

| Ukuxinana | 10.2g/cm3 |

Wechat: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com