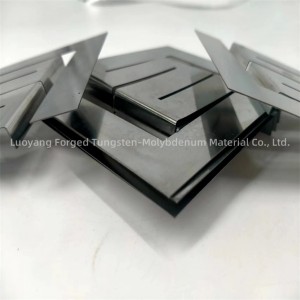

likhoele tse bentšitsoeng tse hloekileng tsa molybdenum liboutu tsa molybdenum

Ho hlahisa lithupa le liboutu tsa molybdenum ho kenyelletsa mehato e 'maloa ea bohlokoa ho fihlela thepa le litekanyo tse hlokahalang. Mona ke lethathamo la mokhoa oa ho e etsa:

1. Khetho ea lintho tse bonahalang: Qala ka lisebelisoa tse tala tsa molybdenum tse phahameng, ho etsa bonnete ba hore li finyella litekanyetso tse hlokahalang tsa bohloeki bakeng sa lithupa le liboutu. Hangata thepa e tla ka mokhoa oa lithupa tsa molybdenum kapa melamu.

2. Ho theha: Thepa ea molybdenum e entsoe ka molamu o hlokahalang oa khoele kapa foromo ea bolt ho sebelisoa mekhoa e kang machining, forging kapa extrusion. Mohato ona o kenyelletsa ho bōptjoa ka mokhoa o nepahetseng ho finyella litekanyo tse khethehileng, litekanyo le litlhaloso tsa khoele tsa motsoako.

3. Phekolo ea mocheso: Lithupa tse entsoeng ka molybdenum tse entsoeng ka likhoele le liboutu li ka ba le ts'ebetso ea kalafo ea mocheso ho ntlafatsa thepa ea bona ea mochini, joalo ka ho ntlafatsa matla, ductility le ho hanyetsa mocheso o phahameng.

4. Phekolo ea holim'a metsi: Likarolo li ka 'na tsa e-ba le ts'ebetso ea ho phekola holimo ho finyella phello e bentšitsoeng. Sena se ka kenyelletsa ho bentša ka mochini, ho bentša ka lik'hemik'hale kapa mekhoa e meng ea ho fetola bokaholimo ho ntlafatsa chebahalo le boreleli ba holim'a lithupa le liboutu.

5. Taolo ea Boleng: Nakong eohle ea ts'ebetso ea tlhahiso, mehato ea taolo ea boleng e kenngoa ts'ebetsong ho netefatsa hore likarolo li kopana le litlhaloso tse hlokahalang tsa dimensional, thepa ea mochine le ho qeta holimo. Sena se ka kenyelletsa tlhahlobo e sa senyeheng, tlhahlobo ea boholo le tlhahlobo ea thepa ho netefatsa boleng ba karolo e felileng.

Ho iketsetsa boholo, sebopeho le bokaholimo bo bentšitsoeng ba lithupa le liboutu tsa molybdenum ho hloka boiphihlelo ba ho sebetsa ka litšepe tse refractory le lisebelisoa tse ikhethileng bakeng sa ho etsa le ho qeta. Ho bohlokoa ho sebetsa le moetsi kapa mofani oa thepa ea nang le boiphihlelo ba ho hlahisa likarolo tsa boleng bo holimo tsa molybdenum ho netefatsa ts'ebetso le ts'epahalo ea sehlahisoa sa ho qetela maemong a hlokang.

Ka lebaka la thepa e ikhethang ea molybdenum, lithupa le liboutu tsa molybdenum li ka sebelisoa maemong a fapaneng a mocheso le maemo a thata. Mona ke lisebelisoa tse ling tse tloaelehileng bakeng sa lithupa le liboutu tsa molybdenum:

1. Likopo tse Phahameng tsa Mocheso: Lithupa le liboutu tsa Molybdenum li sebelisoa libakeng tse phahameng tsa mocheso tse kang ho haha sebōpi, sebaka sa lifofane, le liindasteri tse ling moo ho hanyetsa mocheso o phahameng le matla a mochine a leng bohlokoa.

2. Litikoloho tsa Vacuum le tse phahameng: Ka lebaka la litšobotsi tsa tsona tse fokolang tsa ho ntša metsi le botsitso bo phahameng ba mocheso, likarolo tsena li ka sebelisoa libakeng tse se nang metsi le tse hloekileng. Hangata li sebelisoa lits'ebetsong moo tšilafalo le mesi ea mosi e lokelang ho fokotsoa.

3. Tlhahiso ea Semiconductor: Lithupa le li-bolts tsa Molybdenum li sebelisoa indastering ea semiconductor bakeng sa lisebelisoa tse khethehileng le lisebelisoa tse sebelisoang ho hlahisa likarolo tsa semiconductor. Ho hanyetsa mocheso oa bona o phahameng le thepa e tlaase ea khase e etsa hore e tšoanelehe bakeng sa lits'ebetso tsena.

4. Indasteri ea Khalase le ea Ceramics: Likarolo tsena li sebelisoa lits'ebetsong tse kang ho qhibiliha ha likhalase le ho etsa mekhoa ea indasteri ea khalase le ea ceramics ho fana ka tšehetso ea mohaho le ho hanyetsa mocheso o phahameng.

5. Sefofane le Tšireletso: Lithupa le liboutu tsa Molybdenum li sebelisoa sebakeng sa sefofane le lits'ireletso tse kang ho haha lienjiniere tsa lifofane, likarolo tsa limisaele le maemo a mang a mocheso o phahameng le maemo a khatello ea maikutlo.

6. Lisebelisoa tse sebetsang hantle: tse sebelisetsoang lisebelisoa tse phahameng tsa ts'ebetso le mechine e hlokang ho hanyetsa mocheso o phahameng, matla le ho tšoarella.

Lintho tse khethehileng tsa Molybdenum, tse kenyelletsang sebaka se phahameng sa ho qhibiliha, matla le ho hanyetsa ho bola, li e etsa thepa ea bohlokoa bakeng sa ho sebelisoa libakeng tse thata ho pholletsa le mefuta e fapaneng ea liindasteri. Lithupa le liboutu tsa molybdenum ke karolo ea bohlokoa lits'ebetsong moo lisebelisoa tsa setso li kanna tsa se mamelle maemo a feteletseng.

| Lebitso la Sehlahiswa | likhoele tse bentšitsoeng tse hloekileng tsa molybdenum liboutu tsa molybdenum |

| Lintho tse bonahalang | Mo1 |

| Tlhaloso | Customized |

| Bokaholimo | Letlalo le letšo, alkaline e hlatsoitsoe, e bentšitsoe. |

| Theknoloji | Sintering process, machining |

| Meltng point | 2600 ℃ |

| Botenya | 10.2g/cm3 |

Wechat: 15138768150

WhatsApp: +86 15138745597

E-mail : jiajia@forgedmoly.com