molybdenum lakane molybdenum poleiti molybdenum gasket

Ho hlahisa lishiti le li-gaskets tsa molybdenum hangata ho kenyelletsa mehato e latelang ea bohlokoa:

1. Tlhahiso ea phofo ea Molybdenum: Mokhoa ona o qala ho hlahisa phofo ea molybdenum ka ho fokotsa hydrogen ea molybdenum oxide le theknoloji e meng. Sena se etsa hore ho thehoe phofo e phahameng ea molybdenum.

2. Powder compaction: Phofo ea molybdenum e ntan'o hatelloa ka mokhoa o tiileng ho sebelisa mekhoa e kang ho hatella ho batang kapa ho hatella isostatic. Mohato ona o thusa ho theha 'mele o motala ka sebōpeho le boholo bo lakatsehang.

3. Sintering: 'Mele o motala o chesoa ka mocheso o phahameng sebakeng se laoloang, hangata sebakeng sa vacuum kapa hydrogen. Sintering e thusa ho kopanya likaroloana tsa molybdenum hammoho, ho theha letlapa le matla le le teteaneng la molybdenum kapa thepa ea gasket.

4. Ho roala ho chesang: E le ho hlahisa lipoleiti tsa molybdenum, thepa ea sintered molybdenum e chesa ho phutha ho finyella botenya bo hlokahalang le ho qeta holimo. Ts'ebetso ena e kenyelletsa ho futhumatsa thepa ho mocheso o phahameng le ho e fetisa ka leloala ho fokotsa botenya le ho ntlafatsa thepa ea eona ea mochine.

5. Machining: Letlapa la molybdenum le kolobisitsoeng le etsoa ka mochine ho finyella litekanyo tsa ho qetela le ho qeta holimo ho hlokahalang bakeng sa kopo e khethehileng. Sena se ka kenyelletsa lits'ebetso tse kang ho seha, ho sila kapa ho sila.

6. Taolo ea boleng: Ho pholletsa le ts'ebetso ea tlhahiso, mehato ea ho laola boleng e kenngoa ts'ebetsong ho netefatsa hore lipoleiti tsa molybdenum le li-gaskets li finyella lintlha tse hlokahalang, ho kenyelletsa le ho nepahala ha dimensional, boleng ba holim'a metsi, le thepa ea thepa e kang matla le ductility.

Ka ho latela mehato ena ea tlhahiso, bahlahisi ba ka hlahisa lipoleiti tsa boleng bo phahameng ba molybdenum le li-gaskets tse loketseng mocheso o phahameng le likopo tsa khatello, ho fana ka tiiso e tšepahalang le ts'ebetso libakeng tse hlokang.

Lipoleiti tsa Molybdenum le li-gaskets li na le mefuta e mengata ea lisebelisoa, haholo-holo liindastering moo mocheso o phahameng le maemo a khatello e phahameng a tloaelehileng. Litšebeliso tse ling tse khethehileng tsa lipoleiti tsa molybdenum le li-gasket li kenyelletsa:

1. Sebōpi se phahameng sa mocheso: Lipoleiti tsa Molybdenum li sebelisoa e le lisebelisoa tse futhumatsang, lithebe tsa mocheso le likarolo tsa mohaho libōping tse phahameng tsa mocheso le thepa ea phekolo ea mocheso. Sebaka se phahameng sa ho qhibiliha sa Molybdenum le mocheso o motle oa mocheso li etsa hore e be e loketseng lits'ebetso tsena.

2. Sefofane le Tšireletso: Li-gaskets tsa Molybdenum li sebelisoa sebakeng sa sefofane le lits'ebetsong tsa ts'ireletso ho fana ka tiiso e ka tšeptjoang ka mocheso o phahameng le maemo a khatello e phahameng, joalo ka lienjineng tsa lifofane, litsamaiso tsa rocket propulsion le lisebelisoa tsa sesole tse sebetsang hantle.

3. Ho fehla motlakase: Lipoleiti le likhase tsa Molybdenum li sebelisoa litsing tsa ho fehla motlakase, ho kenyeletsoa le lifeme tsa matla a nyutlelie, bakeng sa likaroloana tsa reactor, litsamaiso tsa mouoane oa mocheso o phahameng oa mocheso, le lisebelisoa tse ling tsa bohlokoa tse hlokang ho tiisoa ka botšepehi le ho hanyetsa ho bola.

4. Ts'ebetso ea lik'hemik'hale: Li-gaskets tsa Molybdenum li sebelisoa lisebelisoa tsa ho sebetsana le lik'hemik'hale, tse kang li-reactors, likepe le tsamaiso ea liphaephe, ho fana ka tiiso e sebetsang hantle libakeng tse senyang le tse phahameng tsa mocheso.

5. Ho etsa lihlahisoa tsa semiconductor: Lipampiri tsa Molybdenum li sebelisoa ha ho etsoa lisebelisoa tsa semiconductor 'me li sebelisoa e le li-substrates, lijana tsa mocheso le likarolo tsa lisebelisoa tsa ho sebetsa ka mocheso o phahameng ka ho fetisisa tlhahiso ea semiconductor.

Lits'ebetsong tsena, lipoleiti tsa molybdenum le li-gaskets li fana ka thepa e ntle ea mocheso le mochini, hammoho le ho hanyetsa kutu le mocheso o phahameng, e leng se etsang hore e be tse loketseng ho sebelisoa libakeng tse thata tsa indasteri.

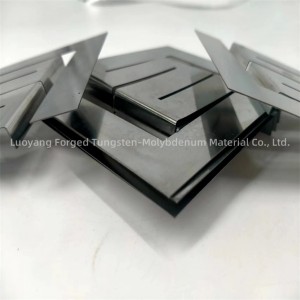

| Lebitso la Sehlahiswa | Letlapa la Molybdenum Molybdenum Gasket |

| Lintho tse bonahalang | Mo1 |

| Tlhaloso | Customized |

| Bokaholimo | Letlalo le letšo, alkaline e hlatsoitsoe, e bentšitsoe. |

| Theknoloji | Sintering process, machining |

| Meltng point | 2600 ℃ |

| Botenya | 10.2g/cm3 |

Wechat: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com