molybdenum round rod for High-themperature sintering and heat heat treatment

Phekolo ea mocheso ea molybdenum hangata e kenyelletsa lits'ebetso tse ntlafatsang thepa ea eona ea mochini joalo ka ductility, ho tiea le matla. Mekhoa e atileng haholo ea kalafo ea mocheso oa molybdenum e kenyelletsa ho fokotsa khatello ea maikutlo le khatello ea maikutlo:

1. Annealing: Hangata molybdenum e anneal ho fokotsa boima ba eona le ho eketsa ductility ea eona. Ts'ebetso ea ho koala hangata e kenyelletsa ho futhumatsa molybdenum ho mocheso o itseng (hangata ho pota 1200-1400 ° C) ebe o e pholisa butle ho mocheso oa kamore. Ts'ebetso ena e thusa ho imolla khatello ea maikutlo le ho tsosolosa sebopeho sa molybdenum, ho ntlafatsa ductility le ho tiea.

2. Khatello ea maikutlo: Likarolo tsa Molybdenum tse kileng tsa sebetsa ka mokhoa o batang haholo kapa machining li ka imolla khatello ea maikutlo ho fokotsa khatello ea kelello ea ka hare le ho ntlafatsa botsitso ba dimensional. Mokhoa ona o kenyelletsa ho futhumatsa molybdenum mocheso o itseng (hangata o pota-potileng 800-1100 ° C) le ho o tšoara ka mocheso oo nako e itseng pele o o pholile butle-butle. Ho imolla khatello ea maikutlo ho thusa ho fokotsa ho khopama le ho fokotsa kotsi ea ho phatloha ha likarolo tsa molybdenum.

Ke habohlokoa ho hlokomela hore mokhoa o khethehileng oa phekolo ea mocheso bakeng sa molybdenum e ka fapana ho itšetlehile ka motsoako oa motsoako, ts'ebeliso e reriloeng le thepa e lakatsehang. Ka hona, ho kgothaletswa ho buisana le setsebi sa thepa kapa ho bua ka tataiso e khethehileng ea phekolo ea mocheso oa molybdenum ho netefatsa phekolo e nepahetseng bakeng sa kopo e fanoeng.

Ho sila ha molybdenum ho kenyelletsa mokhoa oa ho kopanya phofo ea molybdenum le ho e futhumatsa mocheso o ka tlase ho sebaka sa eona sa ho qhibiliha, ho etsa hore likaroloana tsa phofo ka bomong li kopane. Ts'ebetso ena e etsa hore ho thehoe mohaho o tiileng oa molybdenum o nang le matla a ntlafetseng le ho teteana.

Sintering process hangata e kenyelletsa mehato e latelang:

1. Powder Pressing: Sebelisa hlobo kapa die ho hatella phofo ea molybdenum ka sebopeho se batlang. Ts'ebetso ea compaction e thusa ho theha sebopeho se lumellanang ho ba phofo.

2. Ho futhumatsa: Phofo e kopantsoeng ea molybdenum e ntan'o futhumatsoa sebakeng se laoloang ho ea mocheso o ka tlaase ho ntlha ea ho qhibiliha ea molybdenum. Hangata mocheso ona o phahame ka ho lekaneng hore likaroloana tsa phofo li kopane hammoho ka ho hasana, ho etsa sebopeho se tiileng.

3. Densification: Nakong ea ts'ebetso ea sintering, sebopeho sa molybdenum se teteana e le likaroloana tse kopanetsoeng hammoho. Sena se fella ka ho eketseha ha sekhahla le matla a likarolo tsa sintered molybdenum.

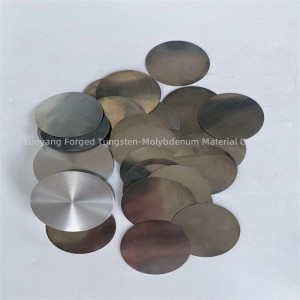

Sintering e atisa ho sebelisoa ho hlahisa likarolo tsa molybdenum tse nang le libopeho tse rarahaneng le litlhoko tse phahameng tsa ho teteana, tse kang lisebelisoa tsa ho futhumatsa, likarolo tsa sebōpi, liketsoana tsa sintering, joalo-joalo Mokhoa ona o hlahisa likarolo tse matla le tse tšoarellang tsa molybdenum tse nang le lisebelisoa tse ntlafetseng tsa mechine tse loketseng likopo tse phahameng tsa mocheso.

Wechat: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com