Bolo ea tungsten e phahameng, boima ba ho tšoasa litlhapi ba Tungsten

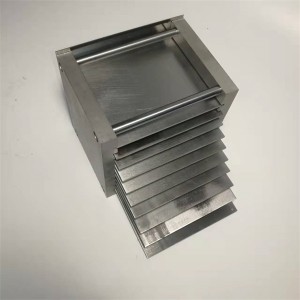

Li-crucible tsa molybdenum hangata li etsoa ho sebelisoa e 'ngoe ea mekhoa e 'meli e meholo ea tlhahiso: Metapo ea phofo: Mokhoa ona o kenyelletsa ho kopanya phofo ea molybdenum, ho e hatella hore e be sebopeho se lakatsehang sa crucible, ebe o tšela phofo e kopantsoeng ka har'a vacuum e phahameng ea mocheso kapa hydrogen. Ts'ebetso ena e thusa ho fihlela boima bo hlokahalang le botšepehi ba sebopeho sa crucible. Machining: Ka mokhoa ona, molamu kapa molamu oa molybdenum o sebelisoa ka lisebelisoa tsa ho seha le lisebelisoa tsa CNC ho betla sebopeho se lakatsehang sa crucible. Mokhoa ona o atisa ho sebelisoa ho hlahisa li-crucible tse nyenyane kapa tse entsoeng ka tloaelo. Maemong ana ka bobeli, mekhoa e eketsehileng e kang ho phekola mocheso, ho qeta holimo, le ho hlahloba boleng ba boleng ho ka etsoa ho netefatsa hore crucible ea ho qetela e kopana le litlhaloso tse hlokahalang. Mekhoa ena e hlahisa li-crucibles tsa boleng bo phahameng tsa molybdenum tse loketseng mefuta e fapaneng ea mocheso o phahameng, joalo ka ho qhibiliha le ho lahlela litšepe, li-ceramics tsa sintering, le mekhoa e meng ea phekolo ea mocheso.

Li-crucible tsa molybdenum li sebelisoa haholo lits'ebetsong tsa mocheso o phahameng, haholo indastering e kang metallurgy, tlhahiso ea likhalase le sintering ea thepa. Litšebeliso tse ling tse khethehileng ke tsena: Ho qhibilihisa le ho etsa lintho tse entsoeng ka tšepe: Lithako tsa molybdenum hangata li sebelisetsoa ho qhibilihisa le ho etsa litšepe tse nang le mocheso o phahameng oa mocheso le motsoako o kang khauta, silevera, le platinum. Sebaka se phahameng sa ho qhibiliha sa Molybdenum le mocheso o motle oa mocheso o etsa hore e be thepa e loketseng bakeng sa ho mamella mocheso o feteletseng o amehang ts'ebetsong ea ho qhibiliha ha tšepe. Sintering: Li-crucibles tsa Molybdenum li sebelisoa bakeng sa ho chesoa ka li-ceramic le li-powders tsa tšepe, moo mocheso o phahameng o hlokahalang ho finyella ho teteana le ho hōla ha lijo-thollo. Inertness ea Molybdenum le bokhoni ba eona ba ho mamella mocheso o phahameng ntle le ho sebetsana le thepa e ntseng e sebetsoa ho etsa hore e be khetho e nepahetseng bakeng sa lits'ebetso tsa sintering. Ho etsa likhalase: Li-crucible tsa molybdenum li sebelisoa ha ho etsoa likhalase tse khethehileng le lirafshoa tsa khalase. Ho tsitsisa ha mocheso o phahameng oa Molybdenum le ho se sebetse ho netefatsa hore ha e silafatse thepa e qhibilihisitsoeng, e leng se etsang hore e be karolo ea bohlokoa ea mokhoa oa ho etsa likhalase. Tlhahiso ea semiconductor: Ka indasteri ea semiconductor, li-crucible tsa molybdenum li sebelisoa bakeng sa kholo le ts'ebetso ea likristale tse le 'ngoe, tse kang silicon le lisebelisoa tse ling tsa semiconductor. Bohloeki bo phahameng le ho hanyetsa lik'hemik'hale ho etsa hore molybdenum e be e loketseng bakeng sa lisebelisoa tsena. Ka kakaretso, li-crucible tsa molybdenum li nkoa e le tsa bohlokoa ka lebaka la ho hanyetsa mocheso o phahameng, ho se sebetse ha lik'hemik'hale, le ho tšoarella nako e telele, e leng se etsang hore e be tsa bohlokoa mefuteng e fapaneng ea mekhoa ea indasteri le ea saense e kenyelletsang lisebelisoa tse chesang haholo le tse sebetsang hantle.

| Lebitso la Sehlahiswa | Mo1 laboratori e sebelisang bohloeki ba molybdenum crucible 99.95% |

| Lintho tse bonahalang | Mo1 |

| Tlhaloso | Customized |

| Bokaholimo | Letlalo le letšo, alkaline e hlatsoitsoe, e bentšitsoe. |

| Theknoloji | Sintering process, machining (tungsten rod hollowing process) |

| Meltng point | 2600 ℃ |

| Botenya | 10.2g/cm3 |

Wechat: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com