heavy alloy tungsten threaded electrode E phahameng thata le segokanyipalo

Tlhahiso ea li-electrode tsa tungsten tse nang le likhoele li kenyelletsa mehato e 'maloa ea bohlokoa ho netefatsa sehlahisoa sa boleng bo holimo, se tšoarellang. Lintlha tse latelang ke kakaretso ea mekhoa e tloaelehileng ea tlhahiso ea li-electrode tsa tungsten:

1. Khetho ea thepa e tala: Ts'ebetso e qala ka ho khetha lisebelisoa tsa boleng bo holimo tsa tungsten. Tungsten e tsebahala ka ho thatafala ha eona ho ikhethang le ntlha e phahameng ea ho qhibiliha, e etsa hore e be e loketseng bakeng sa li-electrode tse nang le likhoele moo ho tšoarellang le ho hanyetsa mocheso ho hlokahalang.

2. Tokiso ea phofo: Etsa lisebelisoa tse tala tsa tungsten tse khethiloeng hore e be phofo e ntle ka ho fokotsa hydrogen kapa ho fokotsa ammonium paratungstate (APT). Phofo ena ke thepa e ka sehloohong bakeng sa tlhahiso ea li-electrode tse nang le thread.

3. Ho kopanya le ho kopanya: phofo ea Tungsten e kopantsoe le likarolo tse ling tsa motsoako ho fumana thepa e lakatsehang, e kang ho eketseha ho thata le ho teteana. Phofo e tsoakiloeng e ntan'o hatelloa ka sebopeho se lakatsehang ho sebelisoa mekhoa e phahameng ea khatello e kang ho hatella isostatic (CIP) kapa ho bōpa.

4. Sintering: Phofo e entsoeng ka tungsten e kopantsoeng e kenngoa ts'ebetsong ea mocheso o phahameng oa mocheso sebakeng se laoloang (hangata sebakeng sa vacuum kapa hydrogen). Sintering e thusa ho kopanya likaroloana tsa tungsten ho etsa sebopeho se teteaneng le se matla.

5. Machining le threading: Ka mor'a ho sintering, thepa ea tungsten e etsoa ka mochine ho fihlela boholo ba ho qetela 'me e kenngoa ka khoele ho etsa sebopeho se lakatsehang sa electrode. Theknoloji ea machining e nepahetseng e sebelisoa ho netefatsa ho nepahala ha likarolo tsa khoele.

6. Kalafo ea holim'a metsi: Li-electrode tse nang le likhoele li ka fumana phekolo ea holim'a metsi tse kang ho sila, ho bentša kapa ho roala ho matlafatsa ts'ebetso ea tsona hammoho le ho senya le ho thibela ho bola.

7. Taolo ea Boleng: Nakong eohle ea ts'ebetso ea tlhahiso, mehato ea ho laola boleng e kenngoa ts'ebetsong ho netefatsa hore li-electrode tsa threaded li kopana le boima bo hlokahalang, boima, ho nepahala ha dimensional le lintlha tse ling tsa bohlokoa tsa parameter.

Ka ho latela mehato ena ea tlhahiso, bahlahisi ba ka hlahisa li-electrode tsa tungsten tse nang le li-electrode tse thata haholo, tse teteaneng le tse tšoarellang, tse etsang hore li tšoanelehe bakeng sa likopo tse hlokang liindasteri tse kang welding, metalworking le electronic discharge machining (EDM).

Li-electrode tse nang le likhoele tsa Tungsten li sebelisoa lits'ebetsong tse fapaneng tsa indasteri ka lebaka la boima ba tsona bo phahameng, ho tiea le ho tšoarella nako e telele. Lisebelisoa tse ling tse tloaelehileng li kenyelletsa:

1. Resistance welding: Tungsten threaded electrode e sebelisoa ts'ebetsong ea ho tjheseletsa e le lintlha tsa ho kopana ho tsamaisa hona joale le ho hlahisa mocheso ho hokahanya likarolo tsa tšepe. Ho thatafala ha Tungsten le ho hanyetsa mocheso ho etsa hore e tšoanelehe ho mamella mocheso o phahameng le likhatello tsa mochini tse kopanang le ts'ebetso ea ho tjheseletsa.

2. Motlakase oa Ts'ebetso ea Motlakase (EDM): Ho EDM, li-electrode tsa tungsten tse entsoeng ka tungsten li sebelisoa e le lisebelisoa tsa lisebelisoa bakeng sa ho bōpa le ho etsa lisebelisoa tsa ho tsamaisa thepa. Ho thatafala ha Tungsten le ho hanyetsa ho apara ho etsa hore e be khetho e babatsehang bakeng sa ho hlahisa likarolo tse rarahaneng tse entsoeng ka mokhoa o nepahetseng ka mokhoa oa EDM.

3. Spark corrosion: Li-electrode tse nang le likhoele tsa Tungsten li sebelisoa ts'ebetsong ea spark corrosion kapa ho bōptjoa e le lisebelisoa tsa elektrode bakeng sa ho theha libopeho tse rarahaneng le likarolo holim'a lisebelisoa tsa tšepe. Tšebeliso e phahameng ea Tungsten le mocheso oa mocheso li thusa ho tlosa thepa hantle le ho sebetsa ka mokhoa o nepahetseng lits'ebetsong tsa khoholeho ea tlhase.

4. Metal Form and Stamping: Li-electrode tse nang le likhoele tsa Tungsten li sebelisoa ts'ebetsong ea ho etsa tšepe le ho etsa setempe ho thusa ho theha, ho otla kapa ho khaola maqephe a tšepe le likaroloana. Ho thatafala ha Tungsten le ho tšoarella ha eona ho etsa hore e tšoanelehe ho mamella matla a mochini a amehang ts'ebetsong ea ho etsa tšepe.

5. Khalase le Ceramic Processing: Li-electrode tse nang le likhoele tsa Tungsten li boetse li sebelisoa ka likhalase le lisebelisoa tsa ho sebetsa ka ceramic bakeng sa ho phunya, ho khaola kapa ho bōpa lintho tsena tse brittle. Ho thatafala ha Tungsten le ho se sebetse ha hae ho etsa hore e be e loketseng bakeng sa ho sebetsa ka nepo indastering ea likhalase le tsa ceramic.

6. Aerospace le Tšireletso: Li-electrode tsa Tungsten tse entsoeng ka marang-rang li sebelisoa mekhoeng e sa tšoaneng ea tlhahiso le tlhokomelo likarolong tsa lifofane le ts'ireletso, ho kenyelletsa le li-welding, machining le lisebelisoa tsa tšepe, tse hlokang ts'ebetso e phahameng le lisebelisoa tse tšoarellang tsa lisebelisoa.

Ka kakaretso, ho thatafala ho hoholo, ho tiea, le ho tšoarella ha li-electrode tsa tungsten li etsa hore li tšoanelehe bakeng sa lits'ebetso tse fapaneng tsa indasteri, haholo lits'ebetso tse kenyelletsang mocheso o phahameng, khatello ea mochini le litlhoko tsa machining tse nepahetseng.

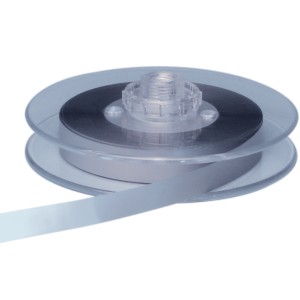

| Lebitso la Sehlahiswa | Tungsten Threaded Electrode |

| Lintho tse bonahalang | W1 |

| Tlhaloso | Customized |

| Bokaholimo | Letlalo le letšo, alkaline e hlatsoitsoe, e bentšitsoe. |

| Theknoloji | Sintering process, machining |

| Meltng point | 3400 ℃ |

| Botenya | 19.3g/cm3 |

Wechat: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com