Molybdenum mandrel fur ee daloolin tuubooyinka birta aan kala go 'lahayn

Soo saarista molybdenum mandiqado ku xidhan sida caadiga ah waxay ku lug leedahay isku darka mashiinada, samaynta biraha iyo hababka dhamaystirka. Kuwa soo socda waa tillaabooyinka caadiga ah ee ku lug leh habka wax-soo-saarka:

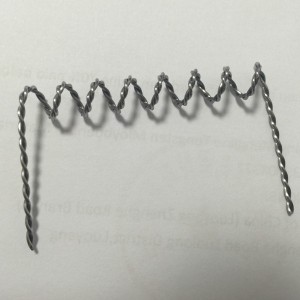

Xulashada alaabta ceeriin: Dooro ulo molybdenum tayo sare leh ama ulo sida alaabta ceeriin ee wax soo saarka ee furayaasha mandrel. Molybdenum waxaa loo doortay barta dhalaalka sare, xoogga iyo caabbinta daxalka, taas oo ka dhigaysa mid ku habboon codsiyada u baahan heerkul sare iyo qalab farsamo. Makiinada: Usha molybdenum-ka waxa lagu farsameeyaa si ay u samaysato qaabka bilowga ah ee furka mandrel. Tani waxay ku lug yeelan kartaa rogid, wax-shiidid ama hawlgallo qodis si loo helo cabbirrada loo baahan yahay iyo guryaha dusha sare leh. CNC (lambarada kombuyuutarka) farsamaynta ayaa u oggolaanaysa qaabaynta saxda ah iyo goynta. Samaynta Birta: Molybdenum-ka bannaan ee mishiinaysan ayaa markaa la marsiiyaa habka samaynta birta sida foorarid, rogid ama extrusion si loo abuuro muuqaalada gaarka ah iyo jaangooyooyinka furka mandrel. Tusaale ahaan, haddii qaab duuban ama koobi ah loo baahan yahay furka mandrel, farsamooyinka samaynta biraha ayaa loo isticmaalaa si loo gaaro joomatari la doonayo. Daawaynta kulaylka: Ka dib samaynta iyo qaabaynta, furka molybdenum mandrel waxa uu mari karaa habka daawaynta kulaylka si kor loogu qaado sifooyinka farsamada sida xoogga iyo adkaanta. Heerkulka sare ee nuugista ama sintering ayaa loo isticmaali karaa in lagu wanaajiyo qaab-dhismeed yar oo meesha laga saaro culaysyada haraaga ah. DHAMMAAN: Baakadaha molybdenum mandrel waxay maraan qalliin dhammaystiran si loo hubiyo saxnaanta cabbirka, simanaanta dusha sare iyo baabi'inta cillad kasta. Tan waxa ku jiri kara dhalaalid, shiidid ama hababka kale ee diyaarinta dusha sare si loo gaadho dhamaystirka dusha sare ee loo baahan yahay iyo dulqaadka joomatari. Xakamaynta Tayada: Inta lagu jiro habka wax soo saarka oo dhan, tallaabooyinka xakamaynta tayada ayaa lafuliyaa si loo baadho loona xaqiijiyo saxnaanta cabbirka, hufnaanta alaabta iyo tayada guud ee xirmooyinka molybdenum mandrel. Hababka baaritaanka aan burburin, cabbir cabbirka iyo kormeerka muuqaalka ayaa laga yaabaa in loo isticmaalo si loo hubiyo u hoggaansanaanta tilmaamaha. Marka la raaco tillaabooyinkan wax-soo-saarka, wax-soo-saarayaashu waxay soo saari karaan mashiinnada molybdenum-ka ee leh sifooyinka iyo sifooyinka waxqabadka looga baahan yahay codsigooda loogu talagalay.

Baakadaha molybdenum mandrel waxaa caadi ahaan loo isticmaalaa tuubooyinka iyo warshadaha wax soo saarka tuubooyinka. Furayaashan waxa lagu dhex geliyaa qaybo bannaan oo bannaan (tubooyinka ama tuubooyinka) inta lagu jiro habka wax-soo-saarka si loo hubiyo saxnaanta cabbirka oo looga hortago cilladaha sida ugxan-sidaha ama gabow-la'aanta. Qalabka molybdenum-ka ayaa loo doortay xooggiisa sare ee heerkulka sare, caabbinta daxalka, iyo awoodda u adkeysiga heerkulka sare iyo cadaadiska ku lug leh habka wax soo saarka tuubooyinka. Codsiyada gaarka ah ee xirmooyinka molybdenum-ka waxaa ka mid ah: Soo saarista tuubooyinka aan cillad lahayn: Molybdenum mander-ka waxaa loo isticmaalaa soo saarista tuubooyinka aan xuduudda lahayn sida samaynta qalab lagu ilaaliyo dhexroorka gudaha iyo tayada dusha sare ee shaqada. Furayaashan mandrel waxay muhiim u yihiin inay hagaan oo ay taageeraan shaqada shaqada si loo gaaro cabbirka la rabo iyo dhammaadka dusha sare sida ay u mareyso daloolinta kuleylka, fidinta iyo geeddi-socodka rogid. Dulitaanka kulul iyo daloolinta: Inta lagu jiro habka rogrogmada kulul iyo daloolinta, molybdenum mandiqadaha mandrel ayaa loo isticmaalaa si looga hortago samaynta laalaabkii, eccentricity iyo cilladaha dusha sare ee tuubooyinka aan fiicnayn. Bixinta taageerada gudaha iyo qaabeynta, mashiinnada mandrel waxay caawiyaan hubinta wax soo saarka tayada sare leh, alaabta la midka ah oo leh cabbir joogto ah. Heerkulka Heerkulka Sare: Isticmaalka molybdenum mander-ka waxay si gaar ah faa'iido ugu leedahay deegaanka wax soo saarka heerkulka sare, halkaas oo maaddada barta dhalaalaysa ee sare iyo sifooyinka kulaylka ee aad u fiican ay u ogolaato inay u adkeysato xaaladaha aadka u daran ee la kulma inta lagu jiro wax soo saarka tuubooyinka.

Isku soo wada duuboo, molybdenum mandiqadaha mandiqada waxay door muhiim ah ka ciyaaraan hubinta saxnaanta cabbirka, tayada dusha sare iyo hufnaanta tuubooyinka aan kala go 'lahayn, ugu dambayntii waxay gacan ka geystaan soo saarista waxqabadka sare ee warshadaha kala duwan sida baabuurta, hawada hawada, saliidda iyo gaaska, iwm.

| Magaca Alaabta | Molybdenum mandrel fur |

| Qalab | Mo |

| Tilmaamid | La habeeyay |

| Dusha sare | Maqaar madow, alkali waa la dhaqay, oo la safeeyey. |

| Farsamada | Habka sintering, machining |

| dhibic dhalaalaysa | 2600 ℃ |

| Cufnaanta | 10.2g/cm3 |

Wechat: 15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com