poto inonyunguduka tungsten crucible yehuni yekupisa yakanyanya

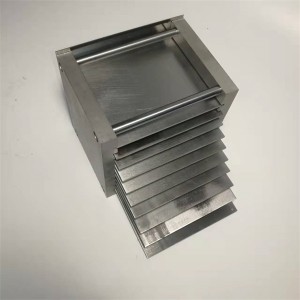

Tungsten crucible imhando yechigadzirwa chesimbi tungsten, inonyanya kukamurwa kuva marudzi maviri: sintering uye stamping. Iyo nzira yekugadzirira ye tungsten crucible inosanganisira spinning type, stamping type, etc. Aya maitiro anoita kuti tungsten crucible iwedzere density, yakaderera pamusoro roughness, yakanaka tensile simba uye kuoma, nepo mutengo wekugadzira wakadzikira, uye mutengo wechigadzirwa zvakare wakaderera. .

Iko kushandiswa kwakakura kwe tungsten crucibles kunobatsira kubva kune yavo yakanakisa yemuviri uye kemikari zvimiro, zvinosanganisira yakakwira kunyungudika, simba repamusoro, yakanaka corrosion kuramba, uye kupfeka kuramba. ,

| Dimensions | Sekuda kwako |

| Nzvimbo Yekwakabva | Luoyang, Henan |

| Brand Name | FGD |

| Application | Indasitiri |

| Surface | Yakanatswa |

| Kuchena | 99.95% Min |

| Material | Tungsten yakachena |

| Density | 19.3g/cm3 |

| melting point | 3400 ℃ |

| Nzvimbo yekushandisa | Vacuum environment |

| Kushandisa tembiricha | 1600-2500 ℃ |

| Main components | W>99.95% |

| Kusachena kwemukati≤ | |

| Pb | 0.0005 |

| Fe | 0.0020 |

| S | 0.0050 |

| P | 0.0005 |

| C | 0.01 |

| Cr | 0.0010 |

| Al | 0.0015 |

| Cu | 0.0015 |

| K | 0.0080 |

| N | 0.003 |

| Sn | 0.0015 |

| Si | 0.0020 |

| Ca | 0.0015 |

| Na | 0.0020 |

| O | 0.008 |

| Ti | 0.0010 |

| Mg | 0.0010 |

| Material | 100% recrystallization tembiricha ℃ | (Annealing nguva: 1 awa)) |

|

| Deformation degree =90% | Deformation degree = 99.99% |

| Akachena W | 1350 | - |

| WVM | - | 2000 |

| WL10 | 1500 | 2500 |

| WL15 | 1550 | 2600 |

| WRe05 | 1700 | - |

| WRe26 | 1750 | - |

1. Fekitari yedu iri muLuoyang City, Henan Province. Luoyang inzvimbo yekugadzira ye tungsten uye molybdenum migodhi, saka isu tine mabhenefiti akakwana mumhando uye mutengo;

2. Kambani yedu ine vashandi vehunyanzvi vane makore anopfuura gumi nemashanu echiitiko, uye isu tinopa zvakanangwa mhinduro uye mazano kune ega ega zvinodiwa nemutengi.

3. Zvose zvezvigadzirwa zvedu zvinoongororwa zvakasimba zvehutano zvisati zvatengeswa kunze kwenyika.

4. Kana ukagamuchira zvinhu zvisina kukwana, unogona kutibata nesu kuti tidzorere mari.

1. Gadzirira tungsten poda

(Chekutanga, gadzira tungsten hupfu uye woivhara kuti iparadzanise yakaomarara uye yakanaka tungsten hupfu)

2. Batch yakasanganiswa

(Batch processing ye tungsten poda ine makemikari akafanana asi kubva kune akasiyana maitiro ekugadzira)

3. isostatic kudzvanya

(Isa iyo yakasanganiswa tungsten poda mumudziyo wakavharwa wakazadzwa nemvura, uye zvishoma nezvishoma uitsigire kuburikidza nepressurization system kudzikisa chinhambwe pakati pemamorekuru, kuwedzera density, uye kugadzirisa humiro hwechinyorwa pasina kushandura chimiro chayo)

4. Rough billet machining

(Mushure mekupedza iyo isostatic kudzvanya, rough billet process inoitwa)

5. Intermediate frequency sintering

(Isa iyo yakagadziridzwa rough billet muchoto chepakati frequency sintering yekushanda sintering)

6. Kugadzirwa kwemotokari kwakanaka

(Kushandura sintered chigadzirwa kuti uwane chaiwo hukuru uye maumbirwo)

7. Ongorora kurongedza

(Ongorora iyo yakagadziriswa tungsten crucible uye ipake iyo mushure mekupfuura ongororo)

Quartz girazi rinonyunguduka: Tungsten crucibles zvakare inoshandiswa zvakanyanya muquartz magirazi ekunyungudutsa mavira. Seimwe yemidziyo yakakosha yekunyungudutsa girazi requartz, kusimba kwavo kwekushisa kwepamusoro uye kusagadzikana kwekuora kunoita kuti girazi requartz rinyunguduke uye kuumba chimiro chinodiwa munzvimbo dzekushisa kwepamusoro.

Iyo deformation ye crucible inokonzerwa nekusaenzana kwekuwedzera kwezvikamu zvakasiyana zve crucible nekuda kwekupisa kwakanyanya uye kusina kuenzana. Kukurumidza uye kusina kuenzana kupisa kwe crucible kunofanira kudziviswa.

Inokurudzirwa tembiricha yemhando ndeye 1600-2500 madhigirii Celsius.