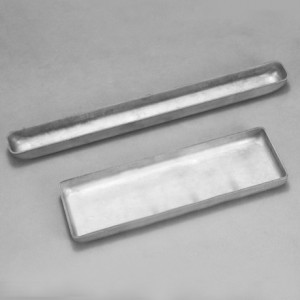

Tantalum screws uye nzungu tantalum fasteners

Iyo nzira yekugadzira ye tantalum bolts uye nzungu inoteedzera zvemhando yepamusoro zviyero kuti ive nechokwadi chekugara uye kuvimbika kwezvigadzirwa. Vanogona kumira zvakanyanya kupisa uye kumanikidza, uye kuchengetedza kuita kwakagadzikana kunyangwe munzvimbo dzakanyanyisa. Naizvozvo, mabhaudhi etantalum nenzungu anowanzo shandiswa mukushandisa zvakanyanya maindasitiri nesainzi, senge aerospace, zvivakwa zvenyukireya, nekugadzira michina yekurapa yepamusoro. ,

| Dimensions | Sekuda kwako |

| Nzvimbo Yekwakabva | Luoyang, Henan |

| Brand Name | FGD |

| Application | Indasitiri,semiconductor |

| Kuchena | 99.95% |

| Melting point | 2996℃ |

| Density | 16.65g/cm3 |

| Kuoma | HV250 |

| λ/nm | f | W | F | S* | CL | G |

| 271.5 | 0.055 | 0.2 | NA | 30 | 1.0 | |

| 260.9(D) | 0.2 | NA | 23 | 2.1 | ||

| 265.7 | 0.2 | NA | 2.5 | |||

| 293.4 | 0.2 | NA | 2.5 | |||

| 255.9 | 0.2 | NA | 2.5 | |||

| 264.8 | 0.2 | NA | x | |||

| 265.3 | 0.2 | NA | 2.7 | |||

| 269.8 | 0.2 | NA | 2.7 | |||

| 275.8 | 0.2 | NA | 3.1 | |||

| 277.6 | 0.2 | NA | 58 |

1. Fekitari yedu iri muLuoyang City, Henan Province. Luoyang inzvimbo yekugadzira ye tungsten uye molybdenum migodhi, saka isu tine mabhenefiti akakwana mumhando uye mutengo;

2. Kambani yedu ine vashandi vehunyanzvi vane makore anopfuura gumi nemashanu echiitiko, uye isu tinopa zvakanangwa mhinduro uye mazano kune ega ega zvinodiwa nemutengi.

3. Zvose zvezvigadzirwa zvedu zvinoongororwa zvakasimba zvehutano zvisati zvatengeswa kunze kwenyika.

4. Kana ukagamuchira zvinhu zvisina kukwana, unogona kutibata nesu kuti tidzorere mari.

1. kugadzirira zvinhu mbishi

(Sarudza zvinhu zvakakodzera zvewaya kana bhodhi kuti uve nechokwadi chekuti zvinhu zvinosangana nezvinodiwa.)

2. Wire processing / stamping

(Waya inogadziridzwa kuita screw blanks kuburikidza nemichina inotonhora yemusoro; Sheets resimbi rinoroverwa kuita ma blank blanks pachishandiswa punch press. Iyi nhanho ndeyekugadzira chimiro chakakosha chebhaudhi nenzungu).

3. kupisa kurapwa

(Kupisa kunobata iyo isina chinhu, sekudzima, kupisa, nezvimwewo, kuwedzera kuomarara uye kuomarara, kuve nechokwadi chemichina yekusimbisa)

4. Kukungurutsa shinda/kurova mazino

(Screw blanks yakarukwa uchishandisa muchina wekutenderedza; Iyo nzungu isina chinhu inogadziriswa neshinda dzemukati pamushini wekutepa)

5.Surface Treatment

(Marapirwo epamusoro senge electroplating, oxidation, phosphating, nezvimwe zvinoitiswa zvinoenderana nezvinodiwa kuti uwedzere corrosion resistance uye aesthetics.

6. kuona

(Shandisa mageji, zviridzwa zvemaziso, nezvimwewo kuongorora zvizere zvigadzirwa zvakapedzwa zvehukuru, huchokwadi hweshinda, hurema hwepamusoro, nezvimwe, kuti uve nechokwadi chemhando)

7. Kuongorora uye Packaging

(Bvisa zvigadzirwa zvisingaenderane nemuchina unozunguza skrini, wozvironga zvinoenderana nezvakatsanangurwa, wobva wazvigadzirisa kana kuzvirongedza nemaoko)

8. kutonga kwehutano

(Sampling yekuyedzwa kwekuita kwemakanika, senge tensile kuyedza, torque kuyedzwa, nezvimwewo, kuona kuti chigadzirwa chinosangana neindasitiri uye zviyero zvevatengi)

Zvinangwa zveMolybdenum zvinowanzo shandiswa muX-ray machubhu ekufungidzira kwekurapa, kuongororwa kwemaindasitiri, uye kutsvagisa kwesainzi. Zvikumbiro zvezvinangwa zvemolybdenum zvinonyanya kugadzira magetsi eX-rays ekufungidzira kwekuongorora, senge computed tomography (CT) scans uye radiography.

Zvinangwa zveMolybdenum zvinofarirwa kune yakakwira kunyungudika, izvo zvinovatendera kuti vamire kutonhora kwakanyanya kunogadzirwa panguva yekugadzirwa kweX-ray. Vanewo maitiro akanaka ekupisa, kubatsira kubvisa kupisa uye kuwedzera hupenyu hwe X-ray tube.

Pamusoro pekufungidzira kwekurapa, zvibodzwa zve molybdenum zvinoshandiswa pakuedza kusiri-kuparadza mumaindasitiri ekushandisa, sekutarisa welds, pombi uye zvinhu zvemuchadenga. Iwo anoshandiswawo munzvimbo dzekutsvagisa dzinoshandisa X-ray fluorescence (XRF) spectroscopy yekuongorora zvinhu uye yekutanga kuzivikanwa.

Kufananidza screws nenzungu kunosanganisira kuona kuti tambo dzema screws nenzungu dzinoenderana. Heano matanho akajairwa ekufananidza screws nenzungu:

1. Sarudza saizi yekukurisa: Edza dhayamita nehurefu hwesiruu kuti uone saizi yayo. Common screw sizes anosarudzwa pachishandiswa nhamba inoteverwa nechidimbu, senge #8-32 kana #10-24.

2. Ziva mhando dzeshinda: Zvipiriso nenzungu zvinogona kuva nemhando dzeshinda dzakasiyana, dzakadai seshinda dzakakora kana shinda dzakatsetseka. Izvo zvakakosha kuti mhando yeshinda ye screw ienderane nati inoenderana.

3. Ongorora kukwirira kweshinda: Kukwirira kweshinda kunoreva nhambwe iri pakati peshinda dziri padyo pascuru kana nati. Ita shuwa kuti screws nenzungu zvine shinda yakafanana pitch yekuona kuti zvinosangana nemazvo.

4. Funga zvekushandisa uye kusimba: Sarudza masiruuru nenzungu dzakagadzirwa kubva mumidziyo inowirirana uye ine mareti esimba akafanana kuti ive nechokwadi chekuti inokwanisa kumirisana nechaitarisirwa.

5. Edzai kukwana: Usati wasarudzwa kwekupedzisira, edza masiruru nenzungu kuti uone kuti zvinopindirana zvakanaka uye zvakachengeteka.

Nekutevera nhanho dziri pazasi, unogona kunyatsofananidza screws nenzungu kune yako chaiyo application.

Kana uchifunga nezve dhizaini yekugadzira tantalum mabhaudhi nenzungu, pane akati wandei akakosha nyaya dzinofanirwa kucherechedzwa nekuda kweiyo tantalum yakasarudzika zvivakwa:

1. Material Compatibility: Tantalum isimbi isingadziviriri, saka zvakakosha kuve nechokwadi kuti zvinhu zvinoshandiswa nuts nemabhaudhi zvinoenderanawo netantalum. Kushandisa zvinhu zvisingaenderani ne tantalum zvinogona kukonzera galvanic corrosion uye kukanganisa kutendeseka kwejoint.

2. Thread lubrication: Tantalum ine tsika yekupfeka, inova nzira yekunamatira zvinhu uye kutamisa pakati penzvimbo inotsvedza. Kuti uderedze dambudziko iri, kukwirisa kwakakodzera kweshinda kunofanirwa kutariswa paunenge uchigadzira tantalum mabhaudhi uye nzungu kudzivirira kusakara uye kuve nechokwadi chegungano rakatsetseka uye disassembly.

3. Simba reshinda: Tantalum isimbi yakapfava, saka kusimba kwechinhu kunofanirwa kutariswa pakugadzira shinda. Izvo zvakakosha kuve nechokwadi kuti iyo tambo fomu uye kubatanidzwa zvinopa simba rakakwana kune yakarongedzerwa application uchidzivirira zvakanyanya kushushikana kushushikana.

4. Thread form: Thread form, ingava metric, yunifomu, kana mamwe mazinga, inofanira kunyatsosarudzwa kuti ive nechokwadi chekuenderana nezvikamu zvekusangana uye kusangana nezvinodiwa chaizvo zvechikumbiro.

5. Surface Finish: Mabhaudhi eTantalum uye nzungu dzinofanirwa kunge dzakatsetseka uye dzakafanana pamusoro pekupedzisira kuti kuderedze mukana wekupfeka uye kuve nechokwadi chekuisa chisimbiso chakakodzera kana chisimbiso chinoratidzwa kune zvinwiwa kana magasi.

Nekugadzirisa nyaya idzi mu tantalum bolt uye nut thread dhizaini, unogona kuve nechokwadi chekuvimbika uye kuita kwemasisitimu ako ekutsanya mumashandisirwo etantalum.