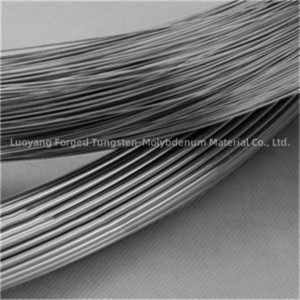

Molybdenum waya yeEDM (Electrical Discharge Machining) yekucheka.

Kugadzirwa kwewaya yemolybdenum yeEDM (Electrical Discharge Machining) yekucheka kunosanganisira matanho akakosha, imwe neimwe yakakosha pakuona kuti waya yemhando yepamusoro, chaiyo, uye maitiro ekuita. Heino mhedziso yeyakajairwa maitiro ekugadzira:

Molybdenum Powder Kugadzirwa

Kucheneswa: Molybdenum ore inonatswa kuti ibudise molybdenum oxide, iyo inobva yaderedzwa kuva molybdenum powder.

Kusanganisa: Hupfu hunosanganiswa kuti huwane makemikari anodiwa.

Upfu Metallurgy

Kudzvanya: Iyo molybdenum poda inotsikirirwa kuita fomu yakamanikana pasi pekumanikidza kwakanyanya.

Sintering: Iyo poda yakasanganiswa inodziiswa muchoto pazasi pekunyungudika kwayo kuti ibatanidze zvidimbu pamwechete, zvichigadzira huremu hwakasimba.

Metal Drawing

Swaging/Hot Drawing: Iyo sintered molybdenum inotanga kuumbwa kuita matanda kuburikidza neinopisa dhizaini kana kufambisa dhizaini, iyo inoderedza dhayamita yayo uye inowedzera urefu hwayo pasina kuchinja huwandu hwayo.

Wire Drawing: Tsvimbo dzinowedzerwazve kuburikidza nenhevedzano yekufa kuti zvishoma nezvishoma kuderedza dhayamita yadzo kusvika kuhukuru hunodiwa hwe EDM wire. Iyi nzira inoitwa pasi pemamiriro ezvinhu anodzorwa kudzivirira kuparara kwewaya uye kuve nechokwadi yunifomu dhayamita.

Kuchenesa uye Kugadzirisa

Kuchenesa: Waya yakadhonzwa inocheneswa kubvisa chero mafuta ekuzora, maokisi, kana zvimwe zvinosvibisa kubva pamusoro payo.

Annealing: Waya inozovharwa, nzira yekurapa kupisa iyo inobvisa kushushikana kwemukati kunokonzerwa panguva yekudhirowa, ichiwedzera ductility yayo uye magetsi conductivity.

Kuongorora uye Packaging

Kudzora Hunhu: Iyo yekupedzisira waya inoedzwa dzakaomesesa yemhando yekudzora bvunzo kuti ione dhayamita, simba rekusimba, mhando yepamusoro, uye zvivakwa zvemagetsi.

Spooling uye Packaging: Kana yatenderwa, waya inoputirwa pamareel ehurefu hwakatarwa uye yakarongedzwa kuti itumirwe, kuve nechokwadi chekudzivirirwa kubva mukukuvadzwa uye kusvibiswa.

Iyi nzira yekugadzira inonyatso kudzorwa uye inotariswa kuti ive nechokwadi chekuti molybdenum waya inosangana nezvinodiwa zvakaomesesa zvinodiwa kuti ishande uye chaiyo EDM yekucheka zvikumbiro.

Precision Metal Cutting

Complex Geometries: Yakanakira kucheka zvimiro zvakaomarara uye zvakanaka maficha mumasimbi akaomarara uye alloys anonetsa muchina nemaitiro echinyakare.

Tight Tolerances: Inogonesa kugadzirwa kwezvikamu zvine hupamhi hwepamusoro uye kushivirira kwakasimba, kwakakosha kune aerospace, mota, uye nemaindasitiri einjiniya.

Mold and Die Kugadzira

Mold Manufacturing: Inoshandiswa mukugadzira molds epurasitiki jekiseni kuumba, kufa casting, uye kugadzira, zvichibvumira kugadzirwa kweakadzama uye akaoma kunzwisisa mold dhizaini.

Die Manufacturing: Yakakosha pakugadzira zvitambi zvinofa, extrusion inofa, uye mamwe marudzi ekufa anoshandiswa mukugadzira simbi.

Aerospace uye Zvemotokari Zvikamu

Aerospace Zvikamu: Inogadzira zvinhu zvine simba uye nemazvo anodiwa kune aerospace application, zvinosanganisira zvikamu zveinjini, giya rekumhara, uye chiridzwa.

Zvikamu zveMotokari: Inoshandiswa kugadzira akakosha emota zvinhu, senge jekiseni nozzles, gearbox zvikamu, uye zvikamu zvine yakaoma geometries.

Medical Device Manufacturing

Zvishandiso Zvekuvhiya: Inogonesa kugadzirwa kwezvishandiso zvakaomarara zvekuvhiya uye zvishandiso, zvichibatsirwa kubva mukugona kwewaya kugadzira machekwa nemaumbirwo chaiwo.

Maimplants: Yakakodzera kugadzira maimplants ekurapa anoda kunyatsojeka uye biocompatibility.

Electronics uye Semiconductor Indasitiri

Semiconductor Equipment: Inoshandiswa mukugadzira semiconductor zvishandiso uye zvikamu, uko kurongeka uye kutendeseka kwezvinhu zvakakosha.

Circuit Board Production: Inobatsira mukugadzirwa kweakadhindwa edunhu mabhodhi (PCBs) uye mamicroelectronic zvishandiso, zvichigonesa kugadzirwa kwemapatani akanaka uye ruzivo.

Molybdenum wire's versatility uye yepamusoro zvivakwa inoita kuti ive sarudzo inosarudzika yekucheka kweEDM pane izvi zvakasiyana-siyana zvekushandisa, kutyaira hunyanzvi uye kunyatsoita mukugadzira.

| Tsanangudzo | Tsanangudzo |

|---|---|

| Diameter | 0.1mm - 0.3mm (zvakajairwa saizi) |

| Material | Molybdenum yakachena |

| Melting Point | Inenge 2623°C (4753°F) |

| Tensile Simba | 700-1000 MPa (zvichienderana nedhayamita) |

| Electrical Conductivity | High |

| Surface Finish | Yakapfava, yakachena, isina kana kukanganisa |

| Spool Size | Inosiyana (semuenzaniso, 2000m, 2400m per spool) |

| Application | Inokodzera yakakwirira-chaiyo EDM yekucheka |

| Features | High durability, kushanda zvakanaka mukucheka |

| Kugarisana | Inoenderana neakasiyana EDM michina |

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com