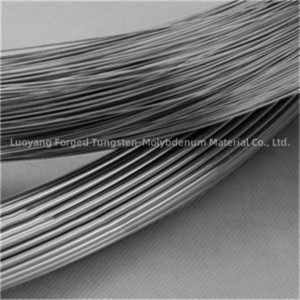

Molybdenum Wire.

| Type | Supplying state | Inokurudzirwa application | |

| 1 | Y - Cold processingR - Kupisa kushandiswa H - Kupisa kurapwa D - Kutambanudza | C - Kemikari kuchenesa E - Electro polishing S - Kururamisa | Grid electrode |

| 2 | Mandrel waya | ||

| 3 | Leading wire | ||

| 4 | Kucheka waya | ||

| 5 | Spraying coating | ||

Chitarisiko: Chigadzirwa hachina hurema hwakaita senge crack, split, burrs, breakage, discolor, waya yenzvimbo yekupa nyika neC, E ichena sirivha, hapafanirwe kuve nekusvibiswa uye pachena oxidation.

Kuumbwa kwekemikari: Type1, Type2, Type3 uye Type4 molybdenum waya 'makemikari ekuumbwa kunofanirwa kuenderana nekutevera zvinotemerwa.

| Kemikari yakagadzirwa(%) | ||

| Mo | O | C |

| ≥99.95 | ≤0.007 | ≤0.030 |

Type5 molybdenum wire kemikari yekemikari inofanirwa kuenderana nezvinotevera.

| Mo(≥) | Zvisina kuchena zvemukati (%) (≤) | ||||||

| 99.95 | Fe | Al | Ni | Si | Ca | Mg | P |

| 0.006 | 0.002 | 0.003 | 0.003 | 0.002 | 0.002. | 0.002 | |

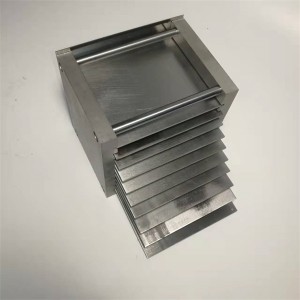

Maererano nemadhayamita akasiyana, pfapfaidzo molybdenum waya dzine marudzi mashanu: Ø3.175mm, Ø2.3mm, Ø2.0mm, Ø1.6mm, Ø1.4mm.

Kushivirira kwedhayamita kwemhando dzewaya dzemolybdenum kunze kweRudzi 5 rwewaya yekupfapfaidza molybdenum inofambirana nezvinodiwa zveGB/T 4182-2003.

Nyora meseji yako pano uye titumire kwatiri