molybdenum round rod for High-temperature sintering and heat treatment industry

Kurapa kwekupisa kwe molybdenum kunowanzo sanganisira maitiro anovandudza ma mechanic zvimiro senge ductility, kuoma, uye simba. Iwo anowanzo zivikanwa molybdenum kupisa kurapa maitiro anosanganisira annealing uye kunyaradza kushushikana:

1. Annealing: Molybdenum inowanzovharwa kuderedza kuoma kwayo uye kuwedzera ductility yayo. Iyo annealing process inowanzo sanganisira kudziyisa molybdenum kune imwe tembiricha (kazhinji inotenderedza 1200-1400 ° C) uye wozoitonhodza zvishoma nezvishoma kusvika kune kamuri tembiricha. Iyi nzira inobatsira kudzoreredza kushushikana kwemukati uye kudzokorodza chimiro che molybdenum, kuvandudza ductility uye kuoma.

2. Kushungurudzika kwekunetseka: Zvikamu zveMolybdenum zvakapinda zvakanyanya kutonhora kushanda kana machining zvinogona kuderedza kushungurudzika kuderedza kushushikana kwemukati uye kuvandudza kugadzikana kwedimensional. Maitiro acho anosanganisira kudziyisa molybdenum kune imwe tembiricha (kazhinji inotenderera 800-1100 ° C) uye kuibata iyo tembiricha kwenguva yakati isati yatonhodza zvishoma nezvishoma. Kusununguka kwekushushikana kunobatsira kuderedza kukanganisa uye kuderedza njodzi yekutsemuka kwezvikamu zve molybdenum.

Zvakakosha kucherechedza kuti iyo chaiyo yekupisa kupisa maitiro e molybdenum inogona kusiyana zvichienderana nekuumbwa kwealloy, chinangwa chekushandisa uye chinodiwa zvinhu zvinhu. Naizvozvo, zvinokurudzirwa kubvunza nyanzvi yezvekushandisa kana kutaura kune chaiyo molybdenum kupisa nhungamiro yekurapa kwakakodzera kurapwa kwakapihwa.

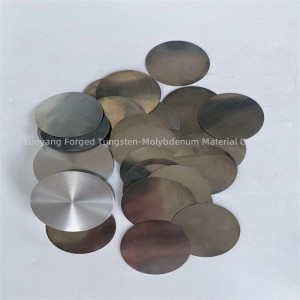

Kunyunguduka kwe molybdenum kunosanganisira kugadzirwa kwe molybdenum poda nekuipisa kusvika patembiricha iri pazasi pekunyungudika kwayo, zvichiita kuti zvidimbu zvehupfu zvibatane. Iyi nzira inoguma mukuumbwa kwechimiro chakasimba chemolybdenum chine simba rakagadziridzwa uye density.

Iyo sintering process inowanzo sanganisira zvinotevera matanho:

1. Kutsikirira kwehupfu: Shandisa mold kana kufa kudzvanya molybdenum poda muchimiro chaunoda. Iyo compaction process inobatsira kugadzira chimiro chakabatana muhupfu.

2. Kupisa: Iyo yakasanganiswa molybdenum poda inobva yapiswa mumhepo inodzorwa kusvika kune tembiricha iri pazasi pekunyungudika kwemolybdenum. Tembiricha iyi inowanzokwira zvakakwana kuti zvidimbu zvehupfu zvibatane kuburikidza nekupararira, zvichigadzira chimiro chakasimba.

3. Densification: Munguva ye sintering process, iyo molybdenum chimiro chinodzikisira sezvimedu zvega zvinobatana pamwechete. Izvi zvinoguma nekuwedzera kuwanda uye kusimba kwe sintered molybdenum zvikamu.

Sintering inowanzoshandiswa kugadzira zvikamu zve molybdenum zvine maumbirwo akaoma uye zvakanyanya kusimba zvinodiwa, zvakadai sekupisa zvinhu, zvikamu zvechoto, zvikepe zvinopisa, nezvimwewo. Nzira yacho inobudisa zvikamu zvakasimba uye zvakasimba zve molybdenum zvine mashizha akagadziridzwa akakodzera kushandiswa kwepamusoro-kupisa.

Wechat:15138768150

WhatsApp: +86 15236256690

E-mail : jiajia@forgedmoly.com