Yepamusoro tembiricha yakakwenenzverwa molybdenum denderedzwa molybdenum chinangwa cheindasitiri yekushandisa

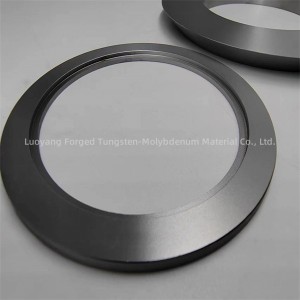

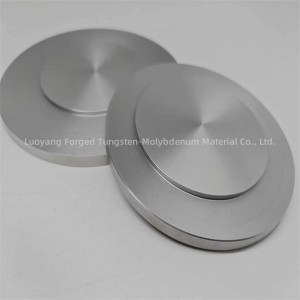

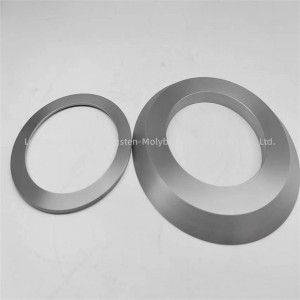

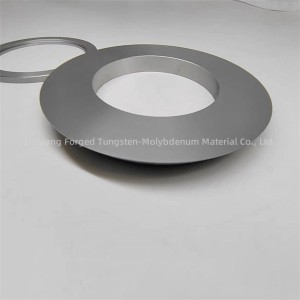

Molybdenum target material ndeye maindasitiri anonyanya kushandiswa munzvimbo dzepamusoro-tekinoroji dzakadai semiconductor kugadzira, nhete yemafirimu deposition tekinoroji, indasitiri yephotovoltaic, uye michina yekufungidzira yekurapa. Yakagadzirwa ne-high-purity molybdenum, ine nzvimbo yakanyanyisa yakanyunguduka, yakanaka magetsi uye inopisa conductivity, iyo inogonesa zvinangwa zve molybdenum kuti zvirambe zvakagadzikana mukupisa kwepamusoro kana kudzvinyirira kwakanyanya. Kuchena kwezvinhu zvinonangwa zvemolybdenum zvinowanzoita 99.9% kana 99.99%, uye zvinotsanangurwa zvinosanganisira denderedzwa tarisiro, maplatifomu, uye zvinotenderedzwa.

| Dimensions | Sekuda kwako |

| Nzvimbo Yekwakabva | Henan, Luoyang |

| Brand Name | FGD |

| Application | Medical, Indasitiri,semiconductor |

| Shape | Round |

| Surface | Yakanatswa |

| Kuchena | 99.95% Min |

| Material | Pure Mo |

| Density | 10.2g/cm3 |

| Main components | Mo>99.95% |

| Kusachena kwemukati≤ | |

| Pb | 0.0005 |

| Fe | 0.0020 |

| S | 0.0050 |

| P | 0.0005 |

| C | 0.01 |

| Cr | 0.0010 |

| Al | 0.0015 |

| Cu | 0.0015 |

| K | 0.0080 |

| N | 0.003 |

| Sn | 0.0015 |

| Si | 0.0020 |

| Ca | 0.0015 |

| Na | 0.0020 |

| O | 0.008 |

| Ti | 0.0010 |

| Mg | 0.0010 |

| Material | Test Temperature(℃) | Kukora kwendiro(mm) | Pre experimental kupisa kurapwa |

| Mo | 1100 | 1.5 | 1200 ℃/1h |

|

| 1450 | 2.0 | 1500 ℃/1h |

|

| 1800 | 6.0 | 1800 ℃/1h |

| TZM | 1100 | 1.5 | 1200 ℃/1h |

|

| 1450 | 1.5 | 1500 ℃/1h |

|

| 1800 | 3.5 | 1800 ℃/1h |

| MLR | 1100 | 1.5 | 1700 ℃/3h |

|

| 1450 | 1.0 | 1700 ℃/3h |

|

| 1800 | 1.0 | 1700 ℃/3h |

1. Fekitari yedu iri muLuoyang City, Henan Province. Luoyang inzvimbo yekugadzira ye tungsten uye molybdenum migodhi, saka isu tine mabhenefiti akakwana mumhando uye mutengo;

2. Kambani yedu ine vashandi vehunyanzvi vane makore anopfuura gumi nemashanu echiitiko, uye isu tinopa zvakanangwa mhinduro uye mazano kune ega ega zvinodiwa nemutengi.

3. Zvose zvezvigadzirwa zvedu zvinoongororwa zvakasimba zvehutano zvisati zvatengeswa kunze kwenyika.

4. Kana ukagamuchira zvinhu zvisina kukwana, unogona kutibata nesu kuti tidzorere mari.

1. Oxide

(molybdenum sesquioxide)

2. Kuderedza

(Chemical kuderedza nzira yekudzikisa molybdenum poda)

3. Kusanganisa nekunatsa alloys

(Kumwe kwehunyanzvi hwedu hwekutanga)

4. Kudzvanya

(Kusanganisa nekutsikirira simbi hupfu)

5. Sinter

(Powder particles dzinodziiswa munzvimbo inodzivirira gasi kuburitsa yakaderera porosity sintered blocks)

6. Tora chimiro

(Iyo density uye simba remagetsi rezvigadzirwa zvinowedzera pamwe nedhigirii rekugadzira)

7. Kurapa kwekupisa

(Kuburikidza nekurapa kwekupisa, zvinokwanisika kuenzanisa kushushikana kwemagetsi, kukanganisa zvinhu zvemukati, uye kuona kuti simbi iri nyore kugadzirisa mune ramangwana)

8. Machining

(Professional machining mutsara wekugadzira unovimbisa huwandu hwekukodzera kwezvakasiyana zvigadzirwa)

9. Kuvimbiswa kwehutano

(Kutora mhando, chengetedzo, uye nharaunda manejimendi masisitimu kuti ive nechokwadi uye nekuenderera mberi nekugonesa chigadzirwa uye sevhisi mhando)

10.Recycle

(Chemical, thermal, uye mechanic treatment yezvigadzirwa zvine chekuita nezvakawanda zvakasara uye zvigadzirwa zvakadzokororwa zvinogona kubatsira kuchengetedza zviwanikwa)

Zvinangwa zveMolybdenum zvinowanzo shandiswa muX-ray machubhu ekufungidzira kwekurapa, kuongororwa kwemaindasitiri, uye kutsvagisa kwesainzi. Zvikumbiro zvezvinangwa zvemolybdenum zvinonyanya kugadzira magetsi eX-rays ekufungidzira kwekuongorora, senge computed tomography (CT) scans uye radiography.

Zvinangwa zveMolybdenum zvinofarirwa kune yakakwira kunyungudika, izvo zvinovatendera kuti vamire kutonhora kwakanyanya kunogadzirwa panguva yekugadzirwa kweX-ray. Vanewo maitiro akanaka ekupisa, kubatsira kubvisa kupisa uye kuwedzera hupenyu hwe X-ray tube.

Pamusoro pekufungidzira kwekurapa, zvibodzwa zve molybdenum zvinoshandiswa pakuedza kusiri-kuparadza mumaindasitiri ekushandisa, sekutarisa welds, pombi uye zvinhu zvemuchadenga. Iwo anoshandiswawo munzvimbo dzekutsvagisa dzinoshandisa X-ray fluorescence (XRF) spectroscopy yekuongorora zvinhu uye yekutanga kuzivikanwa.

Molybdenum inowanzo shandiswa sechinhu chinonangwa mune mammography nekuda kwehunhu hwayo hwakanaka hwekufungidzira mazamu. Molybdenum ine nhamba yeatomu yakaderera, zvinoreva kuti X-rays yainoburitsa ndiyo yakanaka yekufungidzira matishu akapfava sezamu. Molybdenum inogadzira maitiro eX-rays pamazinga akaderera esimba, zvichiita kuti ive yakanaka yekutarisa misiyano isinganzwisisike mukuwanda kwematishu emazamu.

Mukuwedzera, molybdenum ine yakanaka yekupisa conductivity properties, iyo inokosha mumichina ye mammography apo inodzokororwa X-ray inowanzoitika. Iko kukwanisa kubvisa kupisa zvinobudirira kunobatsira kuchengetedza kugadzikana uye kushanda kwe X-ray tubes pamusoro penguva yakareba yekushandiswa.

Pakazere, kushandiswa kwe molybdenum sechinhu chinonangwa mune mammography kunobatsira kukwidziridza kunaka kwekufungidzira kwemazamu nekupa yakakodzera X-ray zvivakwa zveichi application chaiyo.

A sputter target chinhu chinoshandiswa mune yemuviri vapor deposition (PVD) process kugadzira mafirimu matete kana machira pa substrates. Munguva yekupopota, danda reiyoni rine simba guru rinobhomba kunangwa kwekupopotera, zvichiita kuti maatomu kana mamorekuru abudiswe kubva pane zvinenge zvichinangwa. Zvimedu zvakapfapfaidzwa izvi zvinozoiswa pasubstrate kuti iite firimu rakatetepa rine mutsara wakafanana neicho chinangwa chekupopota.

Sputtering targets inogadzirwa kubva kumhando dzakasiyana-siyana, kusanganisira simbi, alloys, oxides uye mamwe makomisheni, zvichienderana nezvinodiwa zvefirimu rakaiswa. Sarudzo ye sputtering target material inogona kukanganisa zvakanyanya zvimiro zveicho firimu, senge magetsi conductivity, optical properties kana magnetic properties.

Zvinangwa zveSputtering zvinoshandiswa zvakanyanya mumaindasitiri akasiyana semiconductor kugadzira, optical coating, uye matete firimu solar maseru. Sputtering targets 'chaiyo kutonga pamusoro peiyo firimu dhizaini inovaita kuti vaome mukugadzirwa kwemhando yepamusoro yemagetsi uye optical zvishandiso.

Pane zvakati wandei zvinotariswa zvinosanganisirwa mukusarudza nekushandisa molybdenum tarisiro yekushanda kwakanyanya:

1. Kuchena uye kuumbwa: High-purity molybdenum target materials inosarudzwa kuti ive nechokwadi chekuenderana uye yakavimbika sputtering performance. Iko kuumbwa kwechinangwa che molybdenum kunofanirwa kuenderana nezvinodiwa zvekuisa firimu, sezvinodiwa zvemufirimu uye maitiro ekunamatira.

2. Chimiro chezviyo: Chenjerera kune chimiro chezviyo chechinangwa che molybdenum sezvo chichakanganisa maitiro ekuputika uye kunaka kwefirimu yakaiswa. Yakanaka-grained molybdenum zvinangwa zvinovandudza sputtering kufanana uye kuita kwemafirimu.

3. Target geometry uye saizi: Sarudza iyo yakakodzera inotarirwa geometry uye saizi kuti ienderane neiyo sputtering system uye maitiro ezvinodiwa. Iyo inonangwa dhizaini inofanirwa kuve nechokwadi chekuita sputtering uye yunifomu firimu deposition pane substrate.

4. Kutonhora uye kupisa kupisa: Kutonhora kwakakodzera uye nzira dzekupisa kupisa dzinofanira kushandiswa kugadzirisa zvinopisa zvinopisa panguva yekuputika. Izvi zvinonyanya kukosha kune zvinangwa zve molybdenum, sezvo zvinotarisana nematambudziko ane chokuita nekupisa.

5. Sputtering parameters: Optimize sputtering parameters dzakadai sesimba, kumanikidzwa, uye gasi kuyerera kuti uwane inodiwa firimu zvinhu uye deposition rates apo kuderedza kukukurwa kwechinangwa uye kuve nechokwadi chenguva yakareba chinangwa chekuita.

.

Nekufunga nezvezvinhu izvi uye kushandisa maitiro akanakisa pakusarudza nekushandisa molybdenum tarisiro, optimal sputtering performance inogona kuwanikwa, zvichikonzera yemhando yepamusoro yakaonda firimu deposition kune akasiyana maapplication.