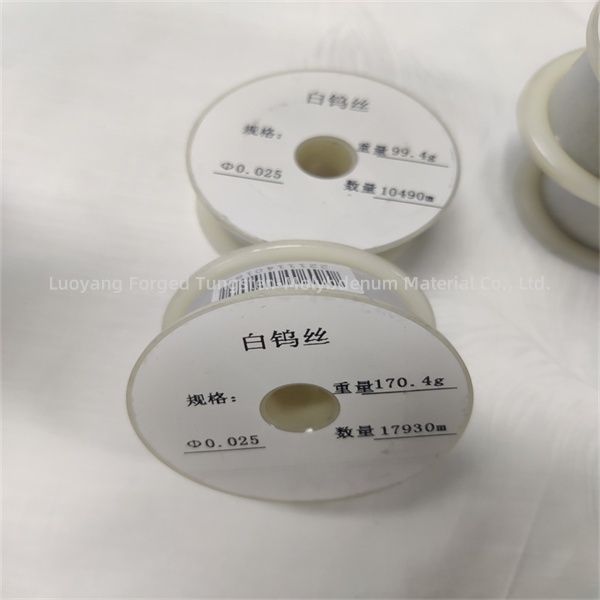

0.025mm tungsten waya 99.95% yakachena tungsten filament

Pamusoro pekushandiswa mumagirobhu emwenje, tungsten waya inoshandiswa zvakanyanya sechinhu chinoburitsa chiedza mune zvimwe zvigadzirwa zvemagetsi sematerevhizheni, masikirini ekuratidzira, lasers, vacuum midziyo yemagetsi, uye machubhu emagetsi. Iyo tungsten waya yemwenje-emitting zvikamu mumidziyo iyi inogona kuburitsa kupenya kwakanyanya, kugadzikana kwakanaka, uye hupenyu hurefu hwemwenje masosi, kusangana neakasiyana maapplication.

| Diameter | Customizable |

| Nzvimbo Yekwakabva | Henan, Luoyang |

| Brand Name | FGD |

| Application | Medical, Heating chinhu, Indasitiri |

| Shape | Straight |

| Surface | Yakanatswa |

| Kuchena | 99.95% Min |

| Material | Akachena W |

| Density | 19.3g/cm3 |

| MOQ | 1kg |

| Iyo dhayamita yezvinhu zvesilikad ,mm | Huremu hwe200mm sirika chikamu, mg | Minimum urefu, m |

| 5≤d≤10 | 0.075~0.30 | 300 |

| 10≤d≤60 | >0.30~10.91 | 400 |

| 60<d≤100 | >10.91~30.30 | 350 |

| 100<d≤150 | >30.30~68.18 | 200 |

| 150<d≤200 | >68.18~121.20 | 100 |

| 200<d≤350 | >121.20~371.19 | 50 |

| 350<d≤700 | / | Yakaenzana nehurefu hwe75g mukurema |

| 700<d≤1800 | / | Yakaenzana nehurefu hwe75g mukurema |

| Iyo dhayamita yesirika ld, μm | Huremu hwe200mm sirika chikamu, mg | Huremu hwe200mm silk segment kutsauka | Diameter kutsauka % | |||

| 0 level | I level | II level | I level | II level | ||

| 5≤d≤10 | 0.075~0.30 | / | ±4 | ±5 | / | / |

| 10≤d≤18 | ~0.30~0.98 | / | ±3 | ±4 | / | / |

| 18≤d≤40 | ~0.98~4.85 | ±2 | ±2.5 | ±3 | / | / |

| 40<d≤80 | >4.85~19.39 | ±1.5 | ±2.0 | ±2.5 | / | / |

| 80<d≤300 | ~19.39~272.71 | ±1.0 | ±1.5 | ±2.0 | / | / |

| 300<d≤350 | >272.71~371.19 | / | ±1.0 | ±1.5 | / | / |

| 350<d≤500 | / | / | / | / | ±1.5 | ±2.0 |

| 500<d≤1800 | / | / | / | / | ±1.0 | ±1.5 |

1. Fekitari yedu iri muLuoyang City, Henan Province. Luoyang inzvimbo yekugadzira ye tungsten uye molybdenum migodhi, saka isu tine mabhenefiti akakwana mumhando uye mutengo;

2. Kambani yedu ine vashandi vehunyanzvi vane makore anopfuura gumi nemashanu echiitiko, uye isu tinopa zvakanangwa mhinduro uye mazano kune ega ega zvinodiwa nemutengi.

3. Zvose zvezvigadzirwa zvedu zvinoongororwa zvakasimba zvehutano zvisati zvatengeswa kunze kwenyika.

4. Kana ukagamuchira zvinhu zvisina kukwana, unogona kutibata nesu kuti tidzorere mari.

1.Kutorwa kwezvinhu zvakasvibiswa

2.chemical treatment

3. Kuderedza kune tungsten powder

4.Kudzvanya uye sintering

5. Kudhirowa

6.Annealing

7. Kurapa kwepamusoro

8. Kudzora Kwehutano

9. Packaging

1. Zvigadzirwa zvemagetsi nemidziyo yekutsvaira: Waya yeTungsten inoshandiswa seyemagetsi emitter uye chinhu chekudziya chepfuti dzemaerekitironi dzinopisa mumashandisirwo akadaro. Iwo anowanzo shandiswa mumidziyo yevacuum senge inopisa erekitironi machubhu, erekitironi maikorosikopu, uye gasi ionization zvishandiso.

2. Munda wekuvhenekesa: Nekuda kwekugona kwayo kubudisa chiedza chakajeka pakupisa kwepamusoro uye kuramba kwayo kuputsika, tungsten wire inoshandiswa zvakanyanya sechiedza chechiedza mumagetsi echinyakare incandescent.

3. Resistance heater: Kunyungudika kwakakwirira uye kupisa kwekushisa kwetambo ye tungsten kunoita kuti ive chinhu chakanaka chekudzivirira kupisa. Anowanzo shandiswa mudzimba uye mumaindasitiri emagetsi ekudziya emagetsi senge chitofu chemagetsi, mahovhoni, uye ma iron.

4. Welding nekucheka: Tungsten wire inowanzoshandiswa se electrode zvinhu mu-high-energy welding uye kucheka maitiro akadai se argon arc welding, laser cutting, uye electron beam welding. Nzvimbo yayo yakakwira yekunyungudika uye kushorwa kwecorrosion kunoita kuti ive sarudzo yakanaka yekutanga arc uye kuburitswa kwazvino mune aya maitiro.

5. Chemical reactors: Mune mamwe makemikari reactors, tungsten waya dzinoshandiswa sechikafu uye zvinhu zvinotsigira kuvandudza kuita kwekuita uye kugadzikana.

Pamusoro pezvishandiso zviri pamusoro, tungsten waya inoshandiswa zvakanyanya muindasitiri yemachira, aerospace, indasitiri yenyukireya, uye minda yekurapa.

Iyo dhayamita yetambo ye tungsten inoda kutariswa zvinoenderana neiyo chaiyo application mamiriro. Kazhinji, iyo dhayamita yakakwenenzverwa, iyo tungsten tambo ichabvaruka zvishoma, asi simba rekutakura mutoro uye hupenyu hwesevhisi huchadzikirawo. Nokudaro, zvakakosha kusarudza maererano nezvinodiwa chaizvo.

Izvo zvinyorwa zve tungsten wire zvine simba guru pakushandiswa kwayo. Yakachena tungsten ine nani-yepamusoro-tembiricha simba uye corrosion kuramba pane tungsten alloy. Nokudaro, mumamiriro ezvinhu apo kuchena kwepamusoro uye kushorwa kwepamusoro kunodiwa, zvinokurudzirwa kusarudza yakachena tungsten waya; Tungsten alloy ine simba riri nani uye ductility, ichiita kuti ive yakakodzera kune mamwe maapplication akakosha senge spark machining, vacuum yemagetsi michina, uye mamwe minda.

Nguva yekunyunguduka kwetambo ye tungsten yakadziirwa muvacuum inoenderana nekunyungudika kwe tungsten. Uye kupisa kwetambo ye tungsten mumhepo kunoburitsa tungsten oxide. Iyo yekunyunguduka kwe tungsten ndeye 3410 madhigirii. Nzvimbo yakanyunguduka ye tungsten oxide, WO3, ndeye 1400-1600 madhigirii. Pasi pemamiriro ekushanda akajairika, tembiricha yefilament inosvika 2500 madhigirii, uye WO3 inokurumidza kunyungudika pakupisa uku, zvichiita kuti filament ikurumidze kunyungudika mumhepo.